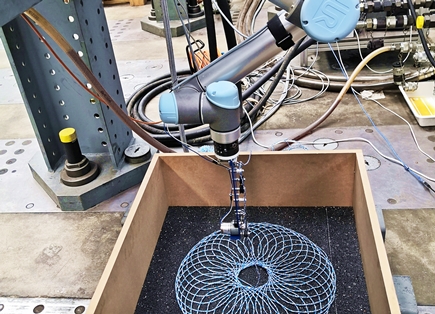

The scientists at the Swiss Federal Laboratories for Materials Testing and Research (Empa) are investigating how roads could be reinforced with simple means and recycled easily after use. Their tools are a robot and a few meters of string. A robotic arm lays out a string in a mandala-like pattern on a bed of gravel.

Empa says this new type of mechanical reinforcement is intended to change the typical structure of the road surface and therefore to help save valuable resources in future or even to recycle road surfaces altogether.

The idea originates from a project of the Gramazio Kohler Research lab at ETH Zurich, which was actually started as an art and research project. Pillars piled up purely from strings and gravel demonstrated that outstanding stability can be achieved by simply interlocking the gravel with a thread – without any cement as a binder. Laboratory tests showed that gravel pillars with a height of 80cm and a diameter of 33cm can withstand a pressure of 200kN (kilonewtons), which corresponds to a load of 20 tonnes.

Asphalt also consists of rocks of various sizes in addition to the liquid binder bitumen. Martin Arraigada and Saeed Abbasion from Empa's Concrete & Asphalt lab transferred this concept to road construction.

"We want to find out how a recyclable pavement could be produced in the future," said Arraigada. "To do this, we are using digitalised construction methods in road construction for the first time."

The researchers say that a string-reinforced road surface that does not require bitumen has a number of advantages. Since bitumen is extracted from crude oil, air pollutants are released during production and also later during use. Bitumen also makes asphalt susceptible to cracking and deformation and impermeable to rainwater – this too could be overcome. For the researchers, it is also conceivable that rock could be used that is otherwise not suitable for road construction, but is less rare. Finally, the new process also allows for a rollable and recyclable pavement.

The two Empa researchers are using various experimental setups to test different solutions, with the robotic arm playing a central role. It places the standard string in a programmed pattern on the layers of gravel stacked on top of each other. For the mechanical tests, five of these layers of gravel and thread are placed on top of each other in a test box, with the floor of the box covered with a rubber mat that fixes the whole package to the ground. It simulates the deformable bed, to which the pavement is applied.

The gravel-thread package is then loaded with a rotating plate and with pressure. The Empa team says this load test shows that, by entangling the individual gravel stones with the thread, the package can withstand a pressure of 5 kN – half a tonne – without the stones moving much. Normally, the binder bitumen performs this task in asphalt. Dynamic load tests with rolling pressure, similar to the extreme conditions road pavements have to withstand, are soon to be carried out.

In parallel to their lab experiments, the researchers model everything in 3D on the computer using the Discrete Element Method (DEM). They says this should reveal the displacement of individual stones and the tensile forces acting on the thread – something that cannot be investigated in the lab. In addition, different patterns and mesh widths and their effects on the stability of the pavement will also be examined in more detail.

Arraigada and Abbasion's research has not yet resulted in a final product that is ready to be used in road construction, but Empa says their investigations provide a lot of innovative potential to get closer to a recyclable and possibly rollable road pavement with simple means.