CDE Global has successfully installed its first AquaCycle system in France at S.A André Boureau’s new sand and gravel pit in Lanty-sur-Aube. The new mobile washing plant is said to be successfully producing commercial products while recycling 90% of the water used in the plant.

Family-owned quarry company located in the Haute-Marne region in north-east France, S.A. André Boureau began operating in 1965. Its quarries produce more than 300,000tonnes of sand, gravel and aggregates every year for use in a wide range of applications including the construction and maintenance of roads. The company’s activities include earthworks, demolition, road works, network creation, equipment hire, and the sale of sand, aggregates and building materials.

In 2014 S.A. André Boureau opened a new sand and gravel pit at Lanty-sur-Aube, a short distance from its existing quarry which has come to the end of its deposits. The company wanted to introduce modern mobile washing technology in order to maximise productivity from the new pit, and to allow the flexibility to move the wash plant as and when necessary. The company’s long-term relationship with Lheureux et Cie, a partner of

In early 2014, CDE became directly involved with S.A. André Boureau on a technical and commercial level. This was the beginning of a close collaboration between client and manufacturer which has resulted in the successful installation of the new plant specified to the exact needs of S.A. André Boureau.

Peter Brewitt, CDE business development manager for France, describes the co-creation process: “The process involved S.A. André Boureau working closely with our technical department to design a system suitable for processing their material. A detailed sieve analysis was carried out which enabled us to design a future proof system specifically for the quarry at Lanty-sur-Aube. The level of communication between Jean-Charles Gillet, Jean-Jacques Boureau and ourselves, ensured we capitalised on the extensive experience of both parties. The level of interaction and shared knowledge involved in this project will benefit both companies long into the future.”

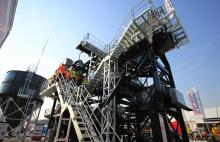

The new plant at Lanty-sur-Aube consists of a M2500 E4 mobile washing plant and an AquaCycle A200 thickener. The plant has a capacity of 100tonnes/hour and is processing 0-60mm alluvial limestone material to produce a 0-4mm washed manufactured sand as well as 4-8mm and 8-20mm washed grit. The retainings, comprised of 20-60mm gravel, are crushed and reintroduced into the installation. The 0-4mm sand product has been produced with maximum retention of +75micron material and the efficient removal of -75micron material. The AquaCycle thickener significantly reduces the area required for ponds onsite at the pit and enables the recycling of more than 90% of the water used in the washing plant, which leads to a substantial reduction in the volume of water that has to be provided for the system.

Jean-Charles Gillet, managing director of S.A. André Boureau, said: “We are concerned with reducing costs, increasing efficiency and reducing our environmental impact. The AquaCycle system guarantees that we can achieve all three of these goals while complying with environmental requirements.” Another important issue for S.A. André Boureau is the health and safety of its employees and the CDE solution has been designed to minimise spillage which ensures a clean and safe site.

Jean-Jacques Boureau, president of S.A. André Boureau, said, “This is our first time using a mobile washing plant and the process with CDE has reassured us we have made the right decision. Their technical expertise, with our input, has guaranteed that we have a washing solution that fulfils our requirements. We were highly impressed with the level of detail explored by CDE to guarantee they delivered a system that was suitable for our needs.”

S.A. André Boureau will celebrate its 50th birthday in 2015 and demonstration events at the Boureau site will take place on 29th and 30th September 2015, giving visitors an opportunity to visit the CDE washing plant and witness the new equipment in operation.