It is a familiar tale across the global aggregates sector. The quarry site’s productivity data is late, unreliable and requires a manual process to gather. The site manager relies on tally sheets and spreadsheets to manage his or her quarry operation, with the large data sets generated needing time to be processed and understood. All this makes it very difficult for the site manager and equipment operators to make informed real-time decisions during their shifts that optimise operational productivity and efficiency.

While the above scenario is common, it does not have to be the norm. Step forward the new operational dashboard for the aggregates industry – Trimble Insight (Insight).

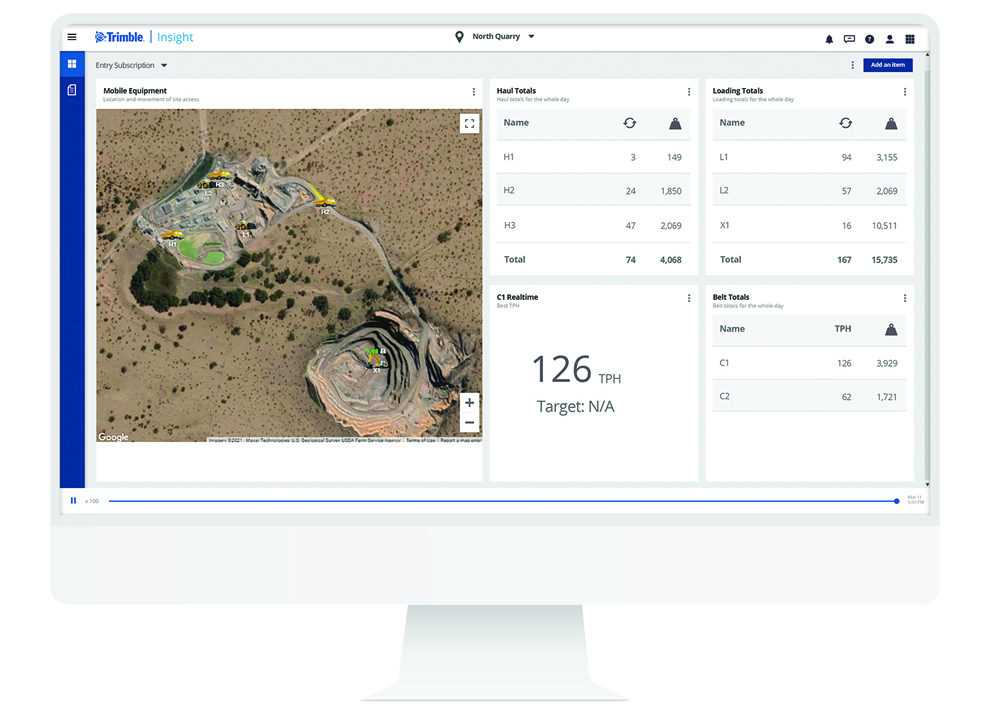

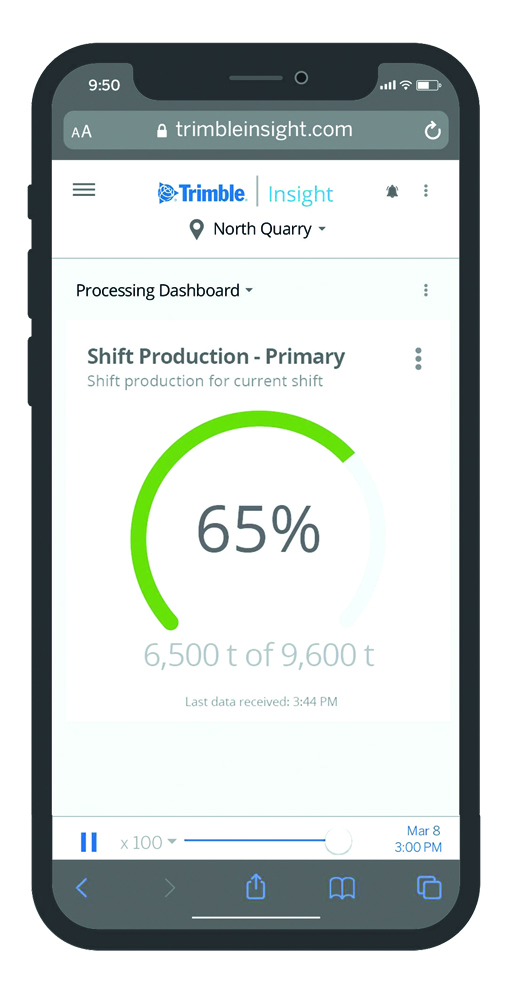

Offering actionable insights to identify, respond to and solve issues, control inventory, and increase productivity, Insight’s real-time access helps you make changes during the shift and see the immediate impact on production. Quarry managers and equipment operators can see target versus actual production, delays, downtime and more, giving quarrying professionals the confidence to make more informed decisions.

As Chris van der Loo, Trimble business area director for Weighing and Aggregates, explains, Insight draws data from Trimble LOADRITE loader, excavator, haul truck and conveyor belt scale sensors into centralised cloud storage. All quarry customer operations data is visible in one place so you can track progress against targets and take action.

“Rather than reporting data to our customer, we want to report insights they can use to make more informed decisions within their quarry operations,” says van der Loo. “Having a place to bring data together from multiple sources puts Insight in a unique position to provide these insights. We can offer an end-to-end solution for our customers.

“Insight has a new dashboard system where we can put a lot of metrics. A new scheduling concept allows you to set production and efficiency targets for a day or a shift and compare throughout the day how you are tracking towards that target. If things are going well, we won’t alert the customers. But if things aren’t going to plan, Insight will send alerts and notifications to the customer’s device, whether it’s a smartphone or computer, to let them know they need to take action to get back on track.”

Van der Loo explains that Insight alerts and notifications can be tailored to various site personnel depending on their responsibilities. “For example, a quarry manager is likely to have a different set of interests to a machine operator, or someone sitting in the C-suite.”

Using full-day or shift-production data (payload, cycle times and speed) overlaid with location, van der Loo says Insight’s animated replay provides an objective view of fleet performance. This may identify, for example, a need for alternative haul plans, incident safety reviews and operator training.

Using full-day or shift-production data (payload, cycle times and speed) overlaid with location, van der Loo says Insight’s animated replay provides an objective view of fleet performance. This may identify, for example, a need for alternative haul plans, incident safety reviews and operator training.

Ready to integrate with an existing quarry business’s systems and processes, van der Loo says Insight offers mixed fleet compatibility provided customers already use Trimble LOADRITE scales on their loading and hauling machines and conveyor belts.

“Having the ability to work across a mixed fleet is an important feature for our customers. Operators need to be trained to use systems like Insight and onboard weighing systems, and if they can be used across different branded wheeled loaders, excavators, and haul trucks, it allows operators to jump on and off a variety of machines while using the same technology.

“We anticipate that Insight will be a platform for all quarries, no matter how big or small. There is strong interest currently from major corporate construction material producers, especially in North America.

“We do have an API [Application Programming Interface] as we recognise there can be multiple technology systems being used in a quarry. We are looking for partners and invite other technology providers to come and integrate with our system via our API.”

Now available to InsightHQ-subscribed quarrying customers, the new second-generation Insight solution has three subscription levels.

“Our U.S. customers that have been working with Insight say they have been using it to validate a lot of changes they are making to their operations. They have also been using Insight to action a lot of those changes,” says van der Loo. “Some of those customers have seen up to 50% productivity improvement in tonnes produced per working hour. We also have customers using Insight in Europe and Asia-Pacific, the latter predominantly based in New Zealand and Australia.”

Citing another example of Insight’s positive impact, van der Loo says a quarry manager wanting to demonstrate the productivity and efficiency gains from a recent investment in an additional haul truck used Insight-processed data to show senior management how the extra truck was benefitting the business.

Van der Loo says using Insight-processed data to lower wheeled loader, excavator and haul truck fuel consumption during operating hours saves money, lowering quarry operators’ cost per tonne. Furthermore, he notes how lower fuel use due to, for example, Insight-prompted action to reduce engine idling time in loading bays or during shift changes or break times, lowers engine emissions, lowering a quarry site’s carbon footprint.

“Insight is targeted towards making quarrying more productive, but with productivity gains, it means machines are used to maximum capacity, with no fuel wastage,” says van der Loo. “With Insight’s alerts and notifications, they indicate, for example, when a crusher or screener is running empty while burning fuel. Insight can also notify the customer when the haul truck is running half full, again wasting fuel. There is also a heat map on the Insight dashboard that shows where haul trucks might be queueing at loading bays for excessive amounts of time.”

Emphasising how Insight is “way beyond a series of point solutions”, van der Loo cites an example of the solution’s effectiveness: “If you know your haul cycles and where your trucks are, you can align that data with the primary crusher and see when the crusher is running empty. You can quickly tell with Insight whether that’s due to a crusher problem or whether it’s a feed issue. We have a special widget within the Insight dashboard that can tell when the material is fed into the crusher. It could be that some material has been dumped in another location, creating a surge pile.

“No one else offers a single solution with sensors on the trucks, loaders, crushers, and conveyor belts that can give you production information in real time in one place.

“The full launch of Trimble Insight is just the start. We plan on developing this product much further than what it already is; that could be through more actionable insights or data brought in from other Trimble or third-party sources that add more value.”

Asked on what parts of a quarrying operation Insight may be used at some stage in future, van der Loo thinks stockpile inventory analytics would be a useful tool for customers. “We already have good data on how much material is going off a conveyor belt into a stockpile, and we give good data showing how much material is being removed from the stockpile by the loader. Given that, there is a great way to track how much real-time inventory is sitting in those stockpiles.

“Other things we will look at with Insight are digital connections beyond the quarry, whether that’s with the concrete plant, the asphalt plant, or the construction site. Trimble has an enormous amount of technology across the aggregates and civil construction continuum. Being able to make quarry material inventory levels data available to the concrete or asphalt plant or the construction site would allow them to know where to send their trucks for material. It will also allow them to trace where materials have come from and where they are located. More connectivity between the on-road haul fleets and the quarries would also be a big help.”

I am curious to know van der Loo’s thoughts on how the quarrying work site will look in a decade and how Insight will evolve to meet customers’ likely future operational needs.

“Insight allows the customer to produce exactly the right amount of material, at the right time, as efficiently as they can. We use data analytics to provide actionable insights, and in ten years, we would have collected an enormous amount of data from using this solution. Machine learning can then be utilised to move us beyond actionable insights to lasting problem eliminations. We are only just at the start of what can be done digitally in the quarrying industry.”