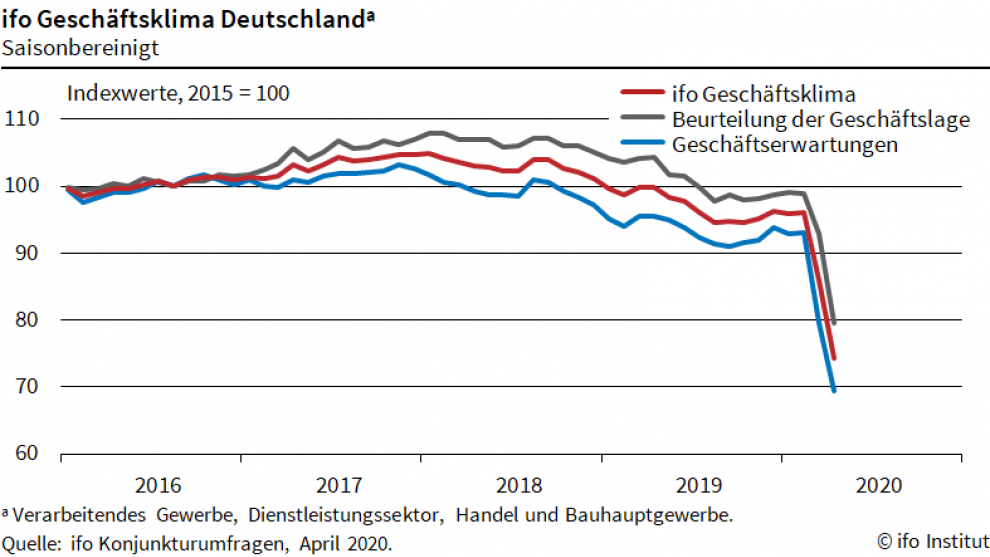

In April 2020 the ifo index for economic activity in Germany fell to the lowest level in its 29-year history.

At the time, the mood among German companies was described as "catastrophic". Is the aggregates and construction materials sector an exception? After all, the Federal Ministry of the Interior, Construction and Home Affairs (BMI) and the Federal Ministry of Transport and Digital Infrastructure (BMVI) gave the green light at the end of March for the continuation of work in building and road construction as well as hydraulic engineering. The fact that construction has continued through the COVID-19 pandemic means that demand for building materials will remain.

The construction industry and its supplier industries should at least take comfort from the wide range of activities they are engaged in. Nevertheless, the ifo index has measured a negative trend, even in the construction industry in terms of future expectations. Apart from the suspicion that funds may not be available to pay for construction work paid in the near future, parts of the construction supply industry depend on components from Asia. Part of this pessimism about the future could, therefore, stem the possibility of breaking supply chains.

In the area of raw mineral and mass building materials production, such supply chain breaks are not a concern as long as they can be made available from German domestic companies. But artificial restrictions also slow down this convenient option. So does the mood change here too? Dr. Gerd Hagenguth, president of the Federal Association of Mineral Raw Materials (MIRO), gives his view on this question and how the German raw materials and building materials industry coming through the crisis?

How do you rate the maintenance of the construction process under conditions even in the Corona high phase?

Dr. Gerd Hagenguth: It's best not to imagine what it would have meant if this area of activity had been paralaysed as it is a major pillar of the domestic economy. Building and delivering building materials doesn't just mean keeping streets, roads or houses maintained. It also means keeping the functionality of other areas including supply and disposal, mobility, the safety of employees and much more. Starting again is difficult enough, and this is why such a stop should not be underestimated from a psychological perspective.

In terms of the psychological aspect our view is that with all the massive cuts that some very hard-hit sectors have to bear, it is not acceptable if other sectors break out into a lament about not being able to generate sales growth compared to the previous year due to corona-related restrictions. A sense of proportion should be preserved here.

What is the situation for companies in the stone industry - did Corona-relevant changes have to be made?

Under more stringent hygiene and health protection measures, our factories in the domestic stone industry are currently continuing to produce in order to meet the continuing demand for building materials. Where close proximity between plant employees and collectors is inevitable, new protective measures have been taken, including additionally installed cut-off wheels and the contactless exchange of forms on the scales.

Larger plants have also made organisational adjustments. They have regrouped and separated their workforces to maintain normal operations in the event of a Corona failure with the unaffected units. The sale of stone products to private end customers was stopped many times for security reasons. With these measures, our industry companies are securing the necessary capacities for ongoing construction projects. We are aware of our social responsibility. Without the necessary replenishment, construction work would also stall. That is exactly what we need to prevent right now!

Has this unprecedented situation led to a greater understanding of the need for areas of cooperation, such as interaction with the authorities?

Unfortunately, this desirable development is rather unconfirmed - even if there may be unknown isolated cases. The relevant laws relating to our sector do not have any exceptions that make it easier. This would have to be legally established first, which would be possible. Various laws to deal with the Corona crisis have been rapidly approved. We have therefore agreed - in accordance with the requirements of the BDI [Federation of German Industries] and others - to ensure that an investment-related backlog can be quickly prevented by law. In the case of approval procedures, digital public participation should be possible today, wherever there are possibilities.

There is still a lot of room for improvement in terms of cutting red tape. I suspect that will only become apparent when the actual economic consequences of the shutdown hit after a time lag but with great force. In my view, it would be much better to encourage all government branches and industries that we actually still have in Germany. I do not mean subsidies or the like here, but above all recognition, process simplification and acceleration instead of further restrictions or additional cost burdens. We need mutual trust when we start pulling the cart back on the road to success. In short: wherever we could have economic independence, we must not lose sight of it.

Can you expand on your comment about the need to avoid "further restrictions or additional cost burdens" on the aggregates sector?

I can do that with a current example. As we learn from our member associations, country-specific costs for fee notices sometimes develop in such a way that one can speak of a real explosion. In Brandenburg, for example, the cost of applications for forest conversion was increased by 40%. Mandatory security deposits come on top of this, and it cannot be explained logically. It borders on highway robbery and does not promote entrepreneurial commitment due to unproductive hurdles that are too high in advance.

What is the significance of industry associations like MIRO in such times?

In my opinion, a very decisive one, at every level! The bundled know-how at our state and regional associations has impressed with an exemplary Corona information offensive. Due to country specifics, the topic is best dealt with there. In addition, a lot of work was done to clarify tariff issues, such as short-time worker regulation. I would like to take this opportunity to compliment our association members. As service providers for their members, they mastered this functional test in an exemplary manner. My fellow MIRO executives, vice presidents Christian Strunk and Thorsten Tonndorf, see it the same way and expressly praise the actors on the front line.

At the same time, our federal association campaigned with parliamentarians and ministries for the interests of our industry at the federal level. We have clearly seen that our range of actions is working as desired, and this confirms our work for the future.

Due to the ban imposed on public assembly, some general meetings of the MIRO associations were postponed until late summer and autumn. Even the 11th steinexpo, which is the most important technical industry event supported by MIRO with technical and ideal support, has had to be postponed to next year.

Do you think such postponements are generally problematic?

I think the time factor - in contrast to the dimmed manufacturing economy - is a negligible factor in this context. Maybe a meeting that is scheduled later will turn out to be an advantage in the end, because we can then deal with an advanced level of the challenges without having to constantly stay in the subjunctive. At least that's my personal hope.

If you were a politician, what would you do first when you return to normality post-lockdown, and which scenario do you think is the most likely, V, U or L? A V scenario: Only short-term cuts and a "return to normal" in a few weeks. A U scenario: Larger government intervention measures and liquidity support are required, as a longer blockade of business activity leads to liquidity problems for many companies. Or an L scenario: Longer-lasting recession with a high number of bankruptcies?

Well, politicians, including Chancellor Angela Merkel, have shown one thing in this phase: they can still make quick decisions, even if they are rather uncomfortable. In doing so, she relied on the expertise of selected scientists and worked comparatively factually. The return to normality and the time afterwards should also be characterised by a willingness to make decisions - at all levels from the municipality to the federal government. Sitting and waiting to see which direction the wind blows has never been a good idea. Political actors are elected precisely because they are trusted to assume responsibility in the sense of maintaining a functioning community.

In the future, uncomfortable courses will have to be set in order to achieve the sustainable protection of our economy. We are, of course, ready for implementation. It's not going to be an easy path - I'm currently assuming a U scenario. In order to not artificially stretch the valley, we have to meet as support partners and solve deadlocked situations in a new way.

Interview republished with the kind approval of MIRO's GP (Rock Prospects) in-house publication.