The crushers in the PRO Line are equipped with efficient, powerful diesel-electric drives. This allows for optional CO2-free operation through external power supply. The operation of the plants is intuitive via the SPECTIVE and SPECTIVE CONNECT control concepts.

MOBICAT MC 120(i) PRO Jaw Crusher

The mobile jaw crusher MOBICAT MC 120(i) PRO features a generously sized feeding unit, allowing for large quantities of material to be easily fed by an excavator or wheel loader. The high performance of the jaw crushing unit is also evident in the dimensions of the crusher inlet, measuring 1,200 x 800 mm, and the extra-long design of the movable jaw, which enables the handling of larger stones without any issues. Despite its impressive size and performance, the machine remains transportable as a single unit. Components such as the foldable side discharge belt, the feeding unit, and the rock hammer are equipped with hydraulic functions and can remain attached to the machine during transport.

MOBICONE MCO 110(i) PRO Cone Crusher

The MOBICONE MCO 110(i) PRO cone crusher is the perfect partner for linked operation with the MOBICAT MC 120(i) PRO jaw crusher. This machine has been specifically designed for the second crushing stage to meet the high demands of natural stone processing in quarries, ensuring both high quality and quantity standards. The machine can be transported as a single unit (excluding the return conveyor) on a low-loader. The simple sliding mechanism of the feeding unit brings the machine into a compact transport position, allowing for quick setup. Additionally, this sliding mechanism offers another advantage: the material discharge curve into the crusher can be easily adjusted, enabling optimal feeding.

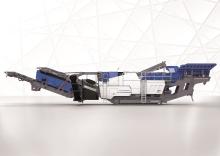

MOBIREX MR 130(i) PRO Impact Crusher

The MOBIREX MR 130(i) PRO covers a wide range of applications in both natural stone and recycling. High product quality is expected from an impact crusher, and the MR 130(i) PRO delivers on this promise with very high production output. This is ensured not only by the proven robust crushing unit with its two impact aprons and versatile strike bar options but also by the optional 8.4 m² double-deck afterscreen. This allows for the production of two classified end products without the need for an additional screening plant, all with just one machine.

Click here to find out more.

Content produced in association with Wirtgen