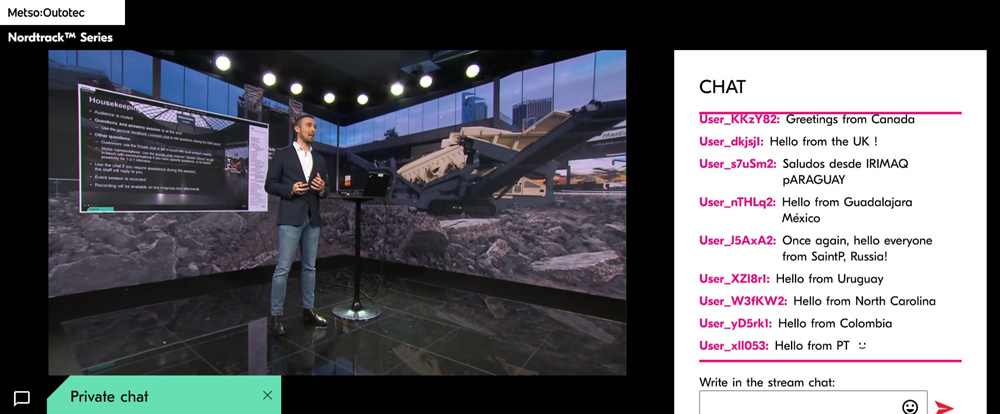

Metso Outotec recently unveiled its Nordtrack Liveroom, the company’s 360° digital event experience platform. Liveroom features 3D demonstrations of the Nordtrack mobile crushing and screening range, as well as a wealth of information on the quarrying and mining solutions giant’s aftermarket offering. The Nordtrack Liveroom launch on 17 March 2021 included the unveiling of two new units - the Nordtrack S2.5 mobile screen and the Nordtrack I908 mobile impact crusher. Afterwards, Guy Woodford caught up with Adrian Wood, Metso Outotec’s Head of Aggregates Equipment Distribution, to learn about the company’s plans over the coming year and beyond

Adrian Wood is on fine form as I chat to him on a Microsoft Teams call. It is pleasing to see him looking and sounding so well given that the Nottingham, England-based UK national, a longstanding Metso Outotec senior executive, was rushed to hospital in early January suffering from an aggressive strain of the coronavirus.

“It hit me suddenly. I couldn’t breathe. I ended up in Nottingham City Hospital for seven days,” Wood recalls. “Before being hit by the virus, I was walking 10 kilometres a day during the pandemic lockdowns. I also play golf and am generally a fit person. I’ve now had my COVID-19 vaccination and feel fine.”

Wood has much to occupy his time on a work front, with Metso Outotec launching new crushing and screening units and the exciting introduction of the Nordtrack Liveroom as aggregates business activity continues to gain momentum after a period of COVID-19-induced disruption.

“I’ve had a lot of feedback today from people that have been really impressed that they can go and look at the equipment, zoom in and get into the detail. A lot of the encouraging comments have come from technically minded people. The team that has developed Nordtrack Liveroom deserve a lot of credit. They have worked so hard to get it ready. It will become a very engaging way of showcasing our products, not just something to use during the coronavirus pandemic.

“We are very focused as a company on safety and our sustainability and global footprint. Any long-distance travel that Nordtrack Liveroom can help cut down on is a good thing. It won’t remove any of our local teams’ interaction with customers, and it may help reduce some of the currently necessary travel that I, product managers and others have to do.”

Wood explains that the Nordtrack Liveroom-launched Nordtrack S2.5 mobile screen and Nordtrack I908 impact crusher are primarily for construction customers but also work well as secondary crushing and screening models for quarrying customers looking to process overburden and fines.

The Nordtrack S2.5 mobile screen is a small size, versatile scalping screen designed for small job sites and a variety of applications. With a compact and light-weight structure, a highly efficient two-deck screen, and a wide selection of different screening media, it is the perfect solution for construction contractors with frequent changes in site locations or simply as a rental unit.

The Nordtrack I908 mobile impact crusher’s design is optimised for the smaller-sized material reduction job sites, and it accepts different kinds of feed material – from asphalt recycling to concrete crushing, as well as traditional rock crushing. The same base model with an integrated screen on the unit, the Nordtrack I908S, was introduced earlier, and it has been one of the best-selling Nordtrack units, especially in Europe.

“Our DNA, for many years, has been focused on large aggregates producers. Our portfolio is very well adjusted for those customers, so the last couple of years have filled the gaps. The launch of Metso Outotec conveyors has been part of that. If you’re buying Lokotrack equipment from Metso Outotec, for example, why would you want to go and buy conveyors from someone else? Buying conveyors as well as crushing and screening equipment from one source enhances process commitment. You can work with one company that is then clearly accountable. Our Nordtrack conveyors are, unit-wise, our top-selling product range, and a range that we will be adding to.”

Wood is also delighted with the popularity of the Nordtrack mobile crushing and screening range. “When we launched it, we were interested to see how it would go, and it’s definitely been a success.

“Germany is a market that is a perfect fit with the Nordtrack range, and its rental business has boomed during the coronavirus pandemic. Nordtrack also has good traction in certain European countries and the U.S., in particular, and Canada, South Africa, Russia, Australia, New Zealand as well as Japan have been good, too. We have very good business partners who are very savvy and really look after customers with our local experts.”

Metso Outotec expects market activity to improve in 2021 after the company recorded a slight drop in annual orders and sales in COVID-19 pandemic-hit 2020. However, this is subject to pandemic-linked developments. Company sales were worth €3.897bn compared to €4.03bn in 2019, with orders received at €4.15bn (€4.37bn in 2019). Despite the robust annual sales and orders, Metso Outotec operating profit in the full-year 2020 fell 40% to €253mn (€423mn in 2019).

“When you look at the quarrying sector, it’s a close-knit community. Our interaction with quarries has not stopped, even if site visits have not been possible in certain countries. Our aftermarket business has been strong as many quarries have been operating throughout the pandemic as they are considered a key industry in a lot of countries worldwide.

“As a company, we are committed to making our Life Cycle Services business even easier to utilise globally.

“We also need to keep the local presence and discussion going. One of the targets of the merger of Metso and Outotec has been making the new combined company even stronger in its relationship with customers; to have customer-centricity by ensuring that we are always there and available to them.”

Wood notes a significant increase in focus on product R&D (research and development) since Pekka Vauramo became CEO of Metso Outotec in November 2018.

“We definitely have seen a far bigger focus on next-generation product development, with the big sustainability part of that something that Pekka has very much brought in. From my own experience, it is very easy for a product manager to become solely focused on and interested in their products and what their competitors are doing and whether we may need to incorporate what others are doing into our own products.”

At the bauma 2019 exhibition in Munich, Germany, the world’s largest construction and quarrying equipment showcase event, a pre-Metso Outotec merger Metso staged the global launch of a claimed ground-breaking truck body innovation for off-highway trucks. Combining the benefits of rubber and high structural strength steel, Metso Outotec’s Truck Body enables mines and quarries to haul more while lowering their operating costs. The launch placed the company’s product offering into completely new territory.

“Power system trends in crushing and screening equipment are changing,” continues Wood. “We had a trend for diesel-hydraulic engines, and now there’s a shift towards diesel-electric ones. You can plug in those units in certain countries but not others, depending on supporting infrastructure.

“There has been a huge focus on driving greater power efficiency without losing production capacity. We are looking at what is the next step in powering our mobile solutions. As a company we’ve committed to efforts to limit global warming to 1.5°C, and our focus is on the development of an environmentally stable portfolio through our Planet Positive initiative. There will be exciting announcements from us in this area in the future.”