Supplying asphalt of the right quality and quantity at the right time is a challenge that requires a perfectly aligned plant solution. When high recycling ratios must also be met while complying with low emission rates, Benninghoven’s hot-gas generator technology is an attractive option. It allows operators to turn 100% reclaimed asphalt into a new asphaltic mixture while complying with Germany’s new TA-Luft standard. This was adapted to the latest technological developments and approved by the German Federal Cabinet on 16 December 2020, following a consultation process lasting several years.

The hot-gas generator technology means that a fresh asphaltic mixture can be made up of 90 + X% re-used asphalt – more than any other recycling system on the market. Benninghoven can also integrate the hot-feed system into existing asphalt-mixing plants as a retrofit solution. However, an example from southern Germany shows why investing in an entirely new asphalt-mixing plant can pay off handsomely.

From the plant’s top platform, 43 metres (m) off the ground, the Kinzigtal valley in the Black Forest looks truly resplendent. The new BA RPP 4000 is 55m tall and makes a majestic impression, even when viewed from the ground. The new asphalt-mixing plant owned by Knäble Straßenbau (Knäble), a medium-sized company from Biberach (Baden), is remarkable in many respects. One of the things that makes it unique is that the BA RPP 4000 replaces a Benninghoven TBA 3000 plant which had reliably supplied asphaltic mixtures to Knäble’s two asphalt crews for ten years. This is not a long time for an asphalt plant, as most Benninghoven plants have 30 to 40 years of service life.

So why did the road construction company, with its rich tradition, invest in new technology rather than a retrofit solution? “As it happens, our planning did start with a retrofit. Ultimately, it was mainly the market environment and our requirements in terms of the technology and its capacity that swayed us toward a brand-new plant,” explains managing director Nicolas Knäble, a member of the fourth generation of the founding family. Another benefit of this approach was that the company did not lose a single day of production. The ‘old’ TBA 3000 kept making the necessary asphaltic mixture until the Benninghoven technicians gave the green light to switch over to the BA RPP 4000 after installation and testing.

From a strategic perspective, Knäble’s investment in the BA RPP 4000 plant is hugely important to the medium-sized road construction company, as the federal state of Baden-Württemberg, where Knäble operates, is committed to maximum recycling. This means that as much reclaimed asphalt as permitted by law is added in when making a new asphaltic mixture. “Re-using materials saves energy and makes a major contribution to climate action,” says the state’s Minister of Transport, Winfried Hermann. The stipulation already led to Baden-Württemberg recycling 2.5 million tonnes of asphalt in 2018, 23% of the volume re-used in Germany and well above average.

The TA-Luft standard (Technical Instructions on Air Quality Control) has now also been adopted. The strict limit values defined in this standard can be met with the Benninghoven plant’s recycling drum using counterflow action with a hot-gas generator. This makes BA RPP plants tailor-made for Knäble’s requirements. ‘RPP’ stands for ‘Recycling Priority Plant’ - a plant that prioritises the material flow for the recycling process and predominantly makes asphalt with higher RAP content.

To integrate the sustainable recycling technology throughout, Knäble wanted a higher mixing capacity of 320 tonnes per hour (tph) instead of the previous level of 240tph. The firm also wanted more user-friendly technology. In the end, Knäble decided to invest in a new BA RPP 4000 plant. The plant also includes two EVO JET 3 burners, one each for the virgin mineral dryer drum and recycling drum. Besides oil and coal dust, these burners can also burn natural gas very efficiently. In the future, this will allow Knäble to respond flexibly to price fluctuations on the energy market and always use the cheapest fuel.

All in all, Knäble is making a genuine investment in the future with its new asphalt-mixing plant. The family-owned company from the central Black Forest region enjoys a rich tradition and employs around 150 staff. The company’s two asphalt crews mostly produce asphaltic mixtures on local road construction sites using Vögele feeders and finishers and Hamm rollers. A Kleemann screening plant and Wirtgen milling machines also form part of the machinery fleet.

Achieving high recycling rates and low emissions simultaneously is only possible by using the counterflow principle combined with a hot-gas generator. Why? Since the old asphalt is heated up, added virgin mineral does not need to be overheated when it is put into the mixing process to reach the necessary temperature, between 140°C and 180°C for warm mix asphalt. The method thus saves a lot of energy as well as emissions.

It is the use of the Benninghoven hot-gas generator that makes the process possible. While direct firing would ‘burn’ the RAP with its bitumen content, the hot-gas generator only heats it indirectly, bringing it gently to its ideal application temperature. The technique also pushes emissions down below the limit stipulated by the TA-Luft, not least because most of the hydrocarbons contained in the exhaust gas stream are burned off simultaneously. Continuous emissions measurements on Knäble’s plants prove that limit values can be constantly held. “Compared with running the old plant, our average recycling rate has increased from 25% to 60%,” reports a proud Myriam Knäble, wife of the managing director. “And, with the hot-gas generator, we’re saving 770 tonnes of CO2 a year.”

This is a huge benefit, particularly considering the introduction of CO2 certificates in Germany. Since the start of the year, companies that bring fuels onto the market have been required to buy emission allowances, better known as CO2 certificates. Initially, they will be charged €25 per tonne of CO2 released through burning heating oil, natural gas, gasoline, and diesel. The federal government will set emission certificate prices during the introductory phase, which lasts until 2025. The price per tonne of CO2 will be €25 in 2021 and increase in stages to €55 by 2025. In 2026, certificates are to be auctioned in a price range of €55-65 for the first time, after which they are expected to be traded freely on the market. Putting a price on CO2 is part of the German government’s Climate Action Programme 2030. Since energy providers pass the costs incurred onto their customers, companies that are energy-efficient and thus have low-emission, environmentally friendly operations will stand to benefit even more in future.

The Benninghoven hot-gas generator is a sophisticated solution that is enjoying increasing popularity in many parts of Europe. At Knäble, too, the technology delivers what Benninghoven promises – a recycling rate of 90 + X%. “We’ve already hit 96% when making the asphaltic mixture for the base,” says Nicolas Knäble. “The quality we achieved when rehabilitating the B 33 federal highway where it passes through Hasslach is spot on. The days of working reclaimed asphalt being a challenge are long gone. Instead, we now need to make sure that we’ve got enough material on stock for our orders that require a specific RAP rate. This is why we’re focusing specifically on bidding for tenders that will get us some reclaimed asphalt, so we don’t run out of the ‘black gold.’”

Although there are now many asphalt-mixing plants capable of producing asphalt containing RAP, the current requirements in the road construction industry are becoming increasingly demanding. For instance, customers are keen on their asphalt having specific properties, such as their colour, elasticity, or stability. Additives are used to achieve these properties, and Knäble has integrated three separate, fully automated systems for their composition. Knäble has a double-dosing unit for powder and granulate, a separate feed system for bulk materials such as Trinidad asphalt or rubber granulate, and a multi-variable RAP feed system that can feed up to 40% reclaimed asphalt into the process cold or non-adhesive bulk materials. This gives Knäble a lot of flexibility.

“These options take our efficiency and productivity to the next level,” Nicolas Knäble says. “With our old plant, two men had to feed several 15-kilogram sacks into the mixer for each batch.” The mixer on the new TBA 3000 plant can produce three tonnes of asphaltic mixture every 45 seconds. “For recipes containing Trinidad asphalt or rubber granulate, i.e., that could only be managed with a bag feed unit in the past, we couldn’t even get close to the maximum possible mixing capacity of 240 tonnes per hour as these special recipes needed a batch time of at least 60 seconds, e.g., due to longer swelling times. The high degree of automation and the four-tonne mixer means that we’re now reaching up to 320 tonnes an hour and are achieving a high mixing capacity even with special recipes with longer batch times.”

Besides the inherently user-friendly plant design, Knäble has also put other aspects in place to ensure first-class working conditions for the plant operator and the entire team. For instance, an elevator takes both personnel and materials up to the top level, allowing all checks and maintenance tasks to be done comfortably. Knäble staff can also look forward to a particular highlight down on the ground: The asphalt-mixing plant’s command centre, at the heart of which is a BLS 3000 Benninghoven control system, is housed in a separate building that is kept at a pleasant temperature throughout the year. From here, staff can keep an eye on all relevant areas of the plant via a CCTV system without leaving their workstations. “If you look at what’s been created here, it’s almost a shame that I’ll be able to retire soon,” says a regretful Reinold Helmut, the plant operator.

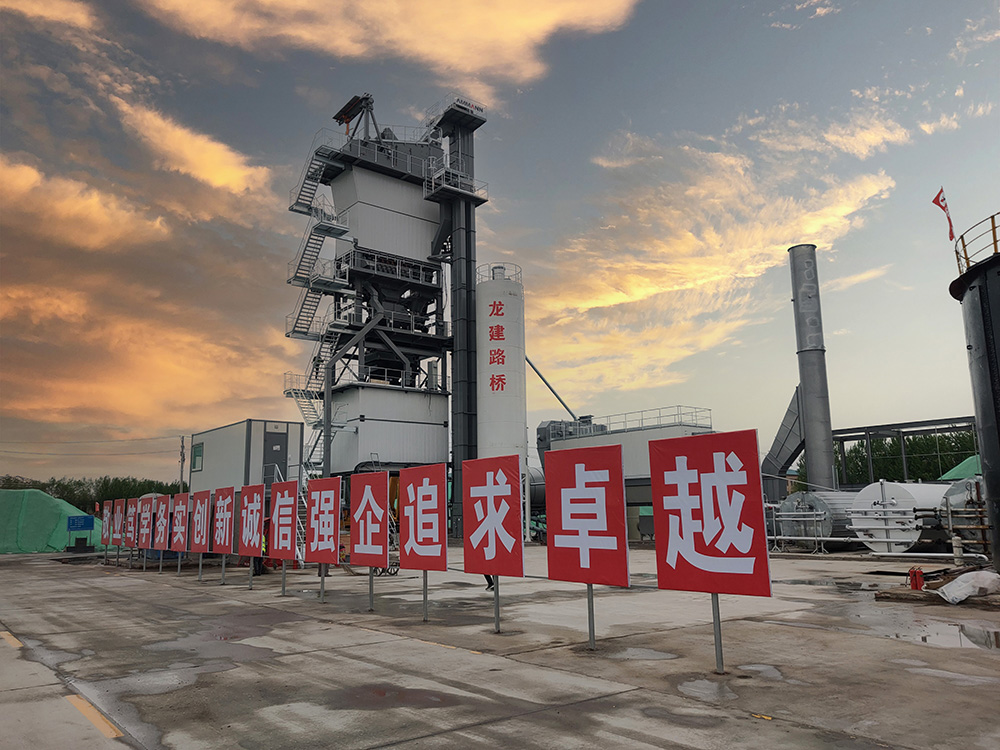

Northeast China is the coldest spot in the country. The annual construction season is much shorter than in other parts of China, so highly efficient and productive equipment is essential.

The construction season, shortened as it is, now includes the A2 section of the Beijing-Harbin Expressway expansion project. Providing mix for this key project is an Ammann ABP 400 Universal asphalt plant. Purchasing the plant, and handling the project, was Longjian Road & Bridge Group (Longjian) and some of its subsidiaries. The plant was installed and commissioned in May 2020. It continues to produce more asphalt for the expansion.

The expressway connects very diverse cities. At one end is Beijing, the capital city with a population of more than 21 million. At the other end is Harbin, known as the ‘Ice City’, with a population of 10 million. Harbin is in the Heilongjiang Province. The expressway is one of the busiest of the six major southbound routes in the province and must be kept open during the expansion.

There was a great deal of optimism around the Beijing-Harbin Expressway project. It was even listed as one of the Top 100 projects in Heilongjiang Province. But it was delayed due to the impact of coronavirus. To get the project back on track, Longjian put the ABP 400 Universal to work. The challenge was to meet production demands that would get the A2 section on schedule.

Longjian is one of the largest, most comprehensive construction groups in northeast China. The company is mainly engaged in highway, bridge, tunnel and municipal construction and engineering. It has tackled various crucial transportation infrastructure projects at home and abroad, with 28 self-invested and 44 holding subsidiaries – and more than 3,000 pieces of construction equipment.

Subsidiary Longjian Equipment Engineering operates 13 asphalt-mixing plants and six pavers.

On 1 September 2020, the 18.5km pavement of the K1172+000-K1190+500 section was finished – right on schedule. It is the most difficult and urgent section of the Beijing-Harbin Expressway project.

As the pace of the project heated up, the Ammann ABP 400 Universal set a single-day production record in the Heilongjiang Province with 8544 tonnes of asphalt in only 21 hours.

In addition, the ABP 400 Universal became the province’s first asphalt-mixing plant with a capacity of 400 tonnes per hour to use natural gas. This confirmed that high production and low fuel consumption could be achieved simultaneously, drawing high praise from the leaders of Heilongjiang Province, Harbin City and governmental transportation departments.

Tian Yulong, chairman of Longjiang Road & Bridge Group, believes that advanced technology is the driving force behind the success of the Ammann asphalt-mixing plant. He thinks it is the foundation of its excellent performance and reliability. He made the statement after assessing the advantages of the plant installation, which saves both time and effort. He also praised detailed reports that meet all needs for production data, efficient energy usage that lowers production costs, sound reduction efforts that create a better working environment, and the as1 Control System – which he described as both powerful and convenient.

With a commitment to “first-class equipment, first-class management and first-class service,” Longjian has purchased another Ammann ABP 400 Universal plant for another section of the A1, the Suihua-Daqing Expressway. In addition, two more of the Ammann ABP 400 Universal plants have been acquired for the A9 and A5 sections of the Harbin-Zhaoyuan Expressway.

The four Ammann ABP 400 Universal plants being utilised by Longjian help make it a strong and powerful construction company in the northeast region and throughout China.

A powerful CSM 4000 asphalt-mixing plant from Lintec is driving the construction of a new airport runway in the harsh surroundings of Western Siberia. Urengoydorstroy, a construction materials supplier, owns the plant providing asphalt each day to the runway rebuilding job at Novy Urengoy Airport, located 4km south of Novy Urengoy Yamalo-Nenets Autonomous Okrug.

Evgeniy Kireev, the chief engineer at Urengoydorstroy, said selecting the right machine for the project was easy.

“We needed a powerful asphalt-manufacturing plant and opted for the Lintec CSM 4000. The demand levels for the airport project are always high, and, since we started, they have increased dramatically. The construction schedule for building the new runway is extremely tight, so as work has progressed, we are even more thankful we can make use of the CSM 4000.”

The CSM 4000 is one of the most powerful units in the range of asphalt-mixing plants from Lintec. It can produce an output of up to 320 tonnes per hour, and on the Novy Urengoy Airport project, it is delivering anything from 2,500 to 3,000 tonnes to the job site each day.

Asphalt-mixing plants from Lintec were the first in the industry to utilise containerised design for optimum transportation, both in terms of speed and cost.

This modularised design makes it quick and easy to put the plants together; and similarly, when it is time to disassemble and move to the next project, the process is equally fast and efficient. Users enjoy the simplicity of the stackable design, while a single, lockable door provides access to the plant tower for maximum security.

Kireev said the technology and design of the CSM 4000 delivered tangible savings on the job site.

“We’ve been using the plant since last summer, and its automated production technology really reduces the manpower we need to commit to asphalt production,” he said. “In addition, we’re really impressed with the quality of asphalt the plant produces, especially given the speed at which it operates.”

The reconstruction of the runway at Novy Urengoy Airport is part of a major upgrade to the regional aviation hub.

Other work in the €40 million infrastructure scheme includes developing a new terminal building covering 18,000m², which will welcome up to 1.45 million passengers a year. Work is being overseen by a local government body, the Airports of Regions Management Company.