The company says that 250kVA generator sets are usually driven by larger engines, and to produce its latest offering it built on proven technologies developed to meet emission regulations for its certified engines, such as its high-pressure common rail technology, hardened block and piston and four-valve cylinder heads.

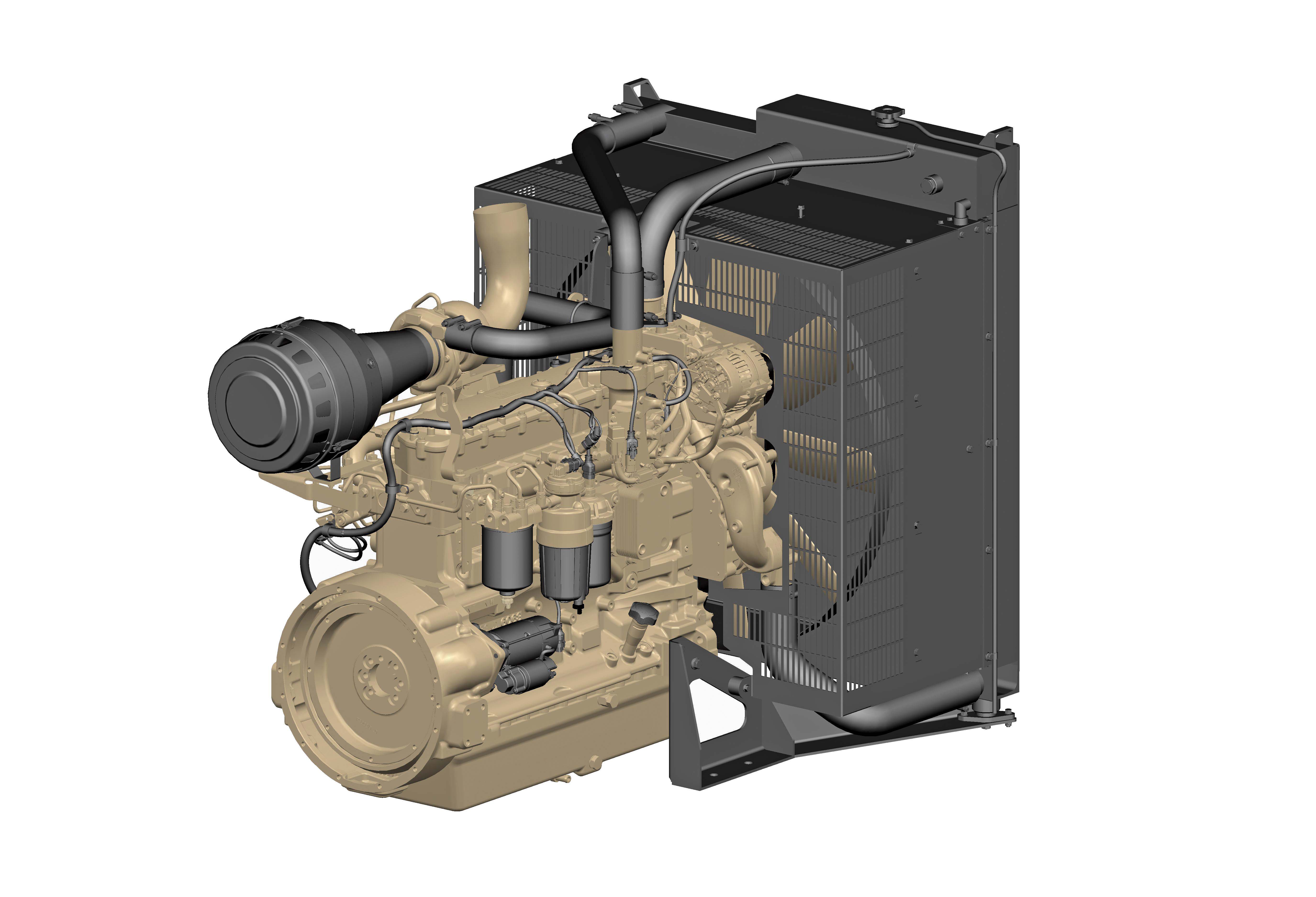

The 250kVA engine is available as a bare engine or as a power unit which includes factory-mounted cooling package and air filter.

“For OEMs, the 6.8litre engine allows them to design smaller canopies. Material, installation and transport costs are reduced, in a solution that is compact yet powerful,” says John Deere.

“With switchable speeds, 1,500 and 1,800rpm, the same engine can be used in 50Hz or 60Hz applications. This reduces the number of different engine references OEMs must store, making stock management easier and more cost-effective. The power unit version decreases development costs as well as time to market.”

In applications where multiple generators run in parallel, the engine’s electronic controls enable unit synchronisation.