Maintaining optimum pressure in the tyres of quarry fleet machinery has many benefits, from prolonging their working life and reducing downtime and associated costs, to improving fleet fuel efficiency and site health and safety. Guy Woodford reports on leading global tyre manufacturers’ innovations in this area, and on other latest product news.

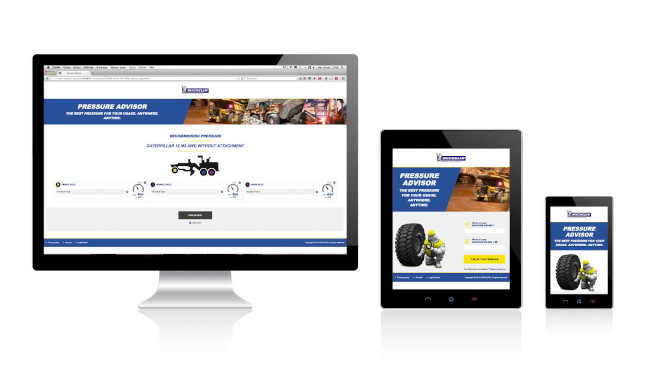

To help customers achieve all-important optimum tyre pressures on their earthmoving/quarry loading and hauling machinery models,

“If you know your machine model’s weight, you can directly use the tool. You can otherwise calculate the weights or ask your service provider to do it for you,” says Lionel Mathat, Michelin - Europe marketing manager OTR Tyres. “If you want to go further, the tool allows you to customise the weight per tyre. If you are involved in really very aggressive or intensive applications, such as marble block handling in a quarry, you have to consult one of our experts for help with this.”

The Michelin Pressure Advisor tool is, Mathat continues, a worldwide service, soon to be available in various languages. “The feedback we have from customers and dealers is very positive, as the tool provides what was a really important missing piece of information. It’s very easy to use. Ideal for people who don’t have the time to look in detail at tyre pressure, perhaps by rooting out machine documentation, but are looking for good advice.”

Emphasising why correct tyre pressure is one of the most important factors to improve a tyre’s longevity, Mathat adds: “If your tyre is 20 per cent under required inflation, you reduce by more than 20% the longevity of the tyre. You can have the best tyre in the world, but if you’re not careful about pressure, you lose money.”

First reported in Aggregates Business magazines’ September-October 2016 issues, Michelin also recently launched its new 40.00 R 57 and 53/80 R 63 XDR3 tyres for rigid dump trucks operating in surface mines. “Our customers are talking about reducing cost and downtime,” says Mathat, stressing that a revolutionary new trend pattern, four new rubber compounds (MB4, MB, MC4, MC) and corrosion isolating steel cables, combine to give a minimum 10% increase in the XDR3’s tyre life compared to its predecessor, the XDR 2. Tyre cost per hour is, therefore, also said to be reduced.

Based in Hanover, Germany,

“We are constantly evaluating the needs of our customers in order to better serve the fields we are active in. Indeed, we are developing and bringing new products to the earthmoving market on a regular basis,” explains Straten. “We launched the first Continental earthmoving products in 2015. These were the first sizes of the EM-Master and the RDT-Master dedicated to machines running in construction or other surface applications. In 2016, we introduced with the ScoopMaster, DrillMaster, DumperMaster, and UndergroundMaster, four additional product lines for underground mining applications. In total, there are more than 30 products that will be available for our customers until the end of 2017. This is a great milestone for us, aligned with our growth strategy.”

Straten is clear on how he believes Continental CST’s tyres for the quarrying sector differ from those of its competitors. “Our main advantage is that we are a full service provider that offers customised solutions for all areas from a single source. Very often the best solution for different vehicles isn’t the one-fits-all-approach. Therefore we bundle our forces from the automotive and the rubber group with the goal to improve customer operations. We call this approach ‘One Continental.’ It allows us to react very quickly to new market developments and customers’ requirements. To exemplify this: Every tyre from the new ContiEarth range already comes with a pre-mounted sensor able to measure tyre pressure and temperature. We all know that the right tyre pressure is essential for safe and efficient operations. This intelligent solution facilitates the tyre management and reduces the cost for the customer.”

Turning his attention to market development and competition, Straten says the market for earthmoving tyres in general can be “very cyclical”, as it depends strongly on the economic situation and factors like the price of raw materials and the level of spending on infrastructure projects. As Continental CST is a globally operating company, Straten sees the company’s main competitors differing from region to region.

Of the impact of telematics on Continental’s quarrying tyre range and performance, Straten says: “A major task for the coming years will be the optimisation of the processes in place at our customer’s sites in order to drive down operating cost. Here, the quote “If you can’t measure it, you can’t manage it” is definitely apt. Intelligent tyres and tyre management systems are needed to provide the necessary data which enables better customer operations management. A first move is our ContiPressureCheck sensor fitted in the tyre, providing data about the tyre pressure and temperature.

“As a solutions provider offering the most comprehensive package to its customers, we foster our approach by delivering the earthmoving product lines directly as iTires, where this sensor is pre-mounted. This is the first step in the direction of ‘intelligent rubber’. We will see further techniques in the upcoming years aiming to drive down operating cost.”

Lindsay Hart, European tyre sales manager at Titan Tyres, sees tyres as quarry and mining machine operators’ one touch point with the surface beneath their vehicle – playing an integral role in both safety and performance. Yet with machinery becoming ever larger and more powerful, Hart believes many people still don’t take the time to specify the perfect tyres for their vehicle.

“Just as racing teams are careful to select the right tyres for their car to ensure they can knock a few vital seconds off the time of a lap, so quarry managers should consider the benefits of upgrading their tyres to fully unlock the potential of new machinery,” argues Hart.

“Tyre dealers will of course be able to assist by advising on the exact specifications that will suit your vehicles, but one style worth asking to see is the low sidewall (LSW) tyre.”

Hart says LSW tyres include a new technology which works by using larger wheels and lower aspect tyres to increase performance. Results include reducing the effect of bouncing and road loping at higher speeds, while also improving lateral stability when working on hillside conditions and around sharp curves.

“To return to the racing analogy, LSW in a construction environment works in much the same way as it does on a sports car,” Hart continues. “You will likely be used to seeing the combination of bigger rims and low profile tyres out on the track, all of which have been designed to help the car stick to the road so that it can get around the track as quickly as possible.

“In a quarry environment it works to very good effect – because the tyre is exactly the same diameter as standard, it will fit the machinery at hand – with benefits for both handling and performance thanks to the fact that the tyres flex less on the road.

Not only that but fuel economy can be improved, making your machinery cheaper to run and helping you to turn a healthier profit.”

Hart argues that ultimately the tyre itself, when selected correctly, will support the continued performance of the vehicles, enabling their capacity to be managed and ensuring they provide the very best value for money.

“Whether you have top of the range machinery or ageing vehicles, kitting them out with the correct tyres will maximise performance, and therefore profit,” she concludes.

Balkrishna Industries (

Available in sizes 18.00 R 33 and 24.00 R 35, the SR 47 has been specially designed for rigid dumpers operating in the toughest material transport applications such as rock quarrying.

The SR 51 and SR 53 are said to be ideal for loaders and dozers operating at rough sites such as quarries and mines. Long tyre life can be expected, says BKT, due to the SR 51’s extra deep tread (L-5 classified) and cut resistant compound.

Basoglu, a retreading firm, is based in the town of Devrek in Zonguldak Province, northern Turkey and, thanks to a good supply of premium new tyres, a professional service through dedicated vans and premium retreaded tyres, it is able to serve big and modern fleets. Recently, through the product RINGTREAD Blackline, Basoglu has been successfully supplying important international long haulage fleets.

Dirkap is based in the Cappadocia region in central Turkey, where, thanks to the high level of quality of its retreaded tyres, it is a key supplier for those fleets seeking reliable and high-performing retreads in order to effectively cut down the total cost of ownership of their operations.

As both new partners were particularly keen to see where the key products used in their business are developed and produced, Necdet Basoglu, with his assistant, Recep Guner, and Bilal Dirlik and Zafer Cetinel - the owners of Dirkap – visited the two Marangoni plants in Ferentino and Rovereto, Northeast Italy. During their visit, they had the opportunity to see how Marangoni works, to meet the engineers and all the people who work on the products and personally check every stage of the manufacturing process.