The new technology is ideal for screening applications challenged with high-moisture content and can handle capacities of up to 3,500 tonnes per hour while minimising water usage.

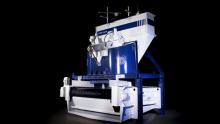

The XL-Class runs in an elliptical motion of up to 6g in a high-moisture iron ore screening application to ensure stratification in all phases of screening. The new vibrating screen also features a robust elliptical exciter drive that offers a bearing life of up to 75,000 hours.

“We are dedicated to using innovative technological solutions to enhance our customers’ daily processes,” said Denilson Moreno, Haver & Boecker Niagara sales manager. “Our new XL-Class design is a prime example of that. The vibrating screen’s unique elliptical movement maintains unrivalled screening performance when processing high-moisture materials.”

Iron ore, for example, contains up to 15% moisture, and often behaves like a pasty, clay-like material, prone to blinding on a screen deck.

The elliptical movement motion and increased acceleration of the XL-Class ensures that the material is stratifying without blinding or contamination.

The elliptical motion XL-Class vibrating screen is available in a wide-range of sizes, in either a single module or tandem design.