“Sub-optimal fragmentation is immediately associated with inefficient excavation and haulage,” said Richards. “Undue damage to crusher parts is another impact. Excessive energy usage, crusher downtime due to wear and tear outside of planned maintenance and delivering out-of-specification product are directly linked to operational performance.”

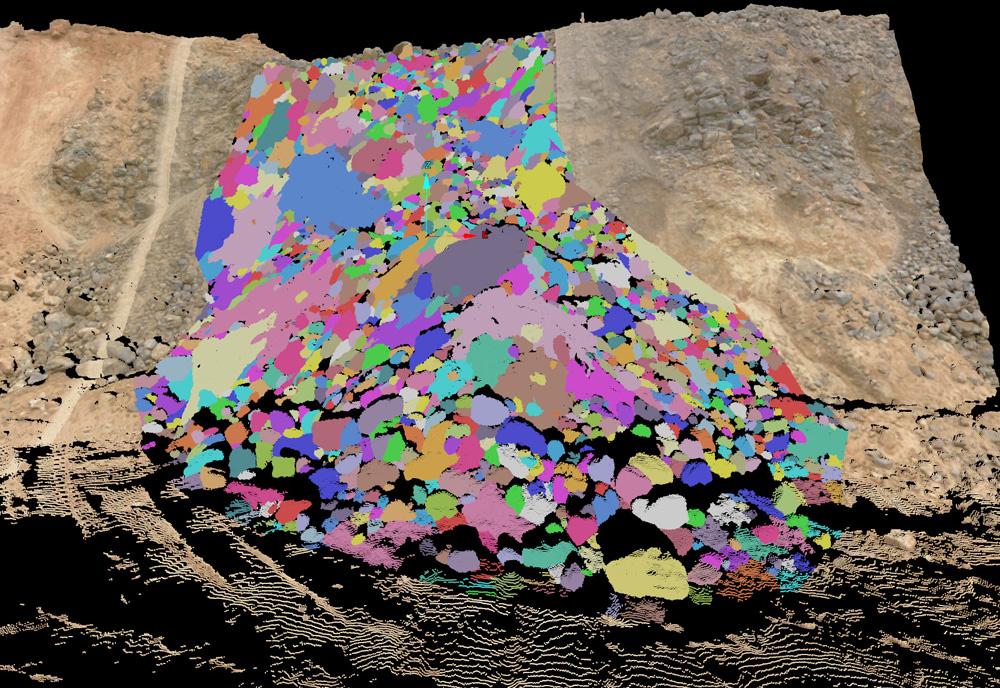

PointStudio Fragmentation Analysis is designed to allow KPIs (key performance indicators) to be achieved consistently. Individual rocks can now be modelled from scanning of muck piles and draw points to provide accurate fragmentation S-curves from blasting or caving operations.

The new tool allows blast engineers and surveyors to quickly assess the condition of blasted rock, ideally before the material heads to the crushing process. Oversize rocks can be isolated for more effective haulage and processing.

Richards said that a simple scan > analyse > report workflow provides a table where rocks outside of spec can be identified and dealt with before the material gets anywhere near the plant.

“A unique feature allows editing rocks or fines in the 3D view and characterising any that are not correctly defined,” he added.

Maptek states that visual and tabular reporting is understandable at a glance so rock can be fed with optimal dimensions for crushing