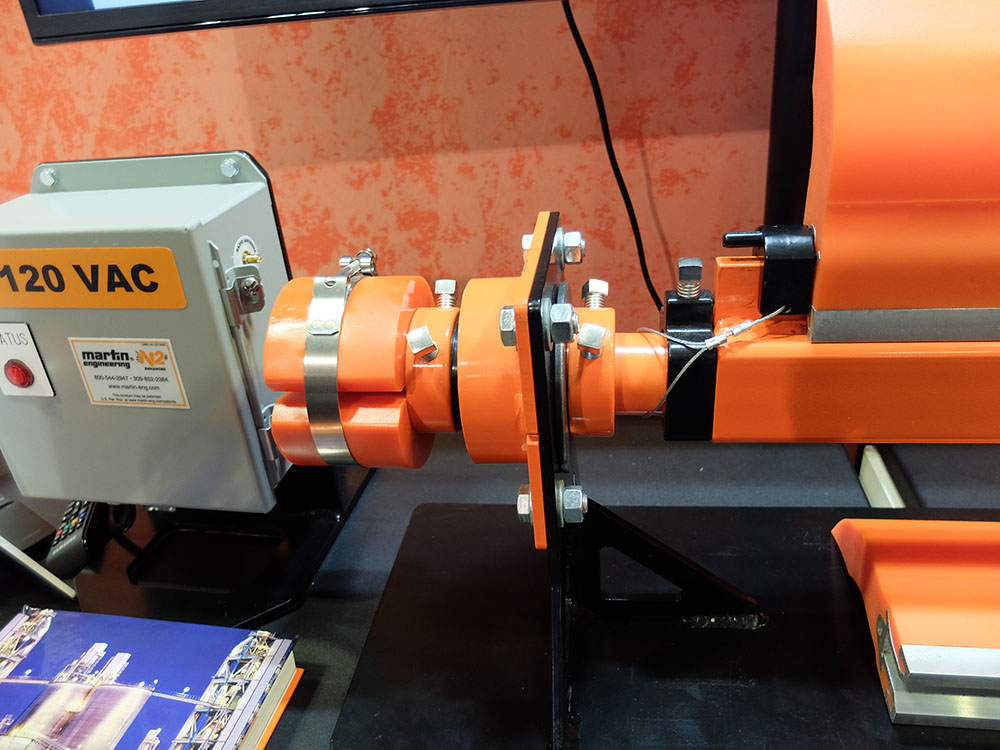

The solution features sensors that measure blade wear and also monitor belt tension. A spokesperson for the firm said: “The sensors fit on the end of the mainframe and measure wear against the belt. They can tell the life of the blade and also the belt tension.”

This can help to optimise belt life and makes a major reduction in maintenance costs. “It takes the guesswork out of maintaining the cleaners.”

The system means that service technicians only have to address scraper wear or blade tension when the sensors show maintenance is needed. This makes a significant saving in eliminating the need for maintenance teams to make periodic checks on conveyors to assess condition. The system also predicts wear so that replacement components can be ordered when they will be required, eliminating the need for stockholding. And as wear can be monitored, this also reduces the risk of unscheduled downtime and helps optimise uptime.