When speaking with contractors and quarry operators about wear parts selection, many are surprised by the impact these parts can have on overall crusher performance and plant profitability. The heart of the plant’s productivity is the crusher, and therefore it must produce at its optimal level. While wear parts in crushing and screening circuit typically contribute less than 10% to plant’s operating costs1, the impact of the right crusher wear selection to profitability can be substantial. In fact, selecting crusher wears based on their impact on productivity and therefore profitability, makes more sense from a business point of view, than only taking the pure cost of the crusher wears into account.

Five key questions to ask

How do you know that you are not maximizing your crusher’s optimal potential?

- Are you producing enough of some specific end-product fraction (desired yield vs. non-saleable product)?

- Is your cost-per-ton at the desired level?

- Is the wear pattern of your crushing chamber smooth and straight?

- Is your crusher’s power consumption steady (no power spikes)?

- Is the scrap percentage of your current wears low?

If your answer to any of these questions is no, changing the chamber design can have a positive impact on your crushing operation.

What drives profitability

The main cost elements in a crushing operation are rock material, drilling, blasting, crushing, loading, hauling and SG&A (selling, general and administrative expenses). In an example case study where the utilization rate is 80%, and the share of waste is 35%, crushing accounts for roughly one fourth of the total costs and the other listed elements make up the rest.

It is important to note that the crushing circuit is the only one of these elements that is producing sales. Another critical point is that these other elements generate three times more costs, and even more importantly, these costs are generated regardless of the performance of the crushing circuit! This means that most of the costs are incurred no matter the crusher utilization rate or the share of desired yield.

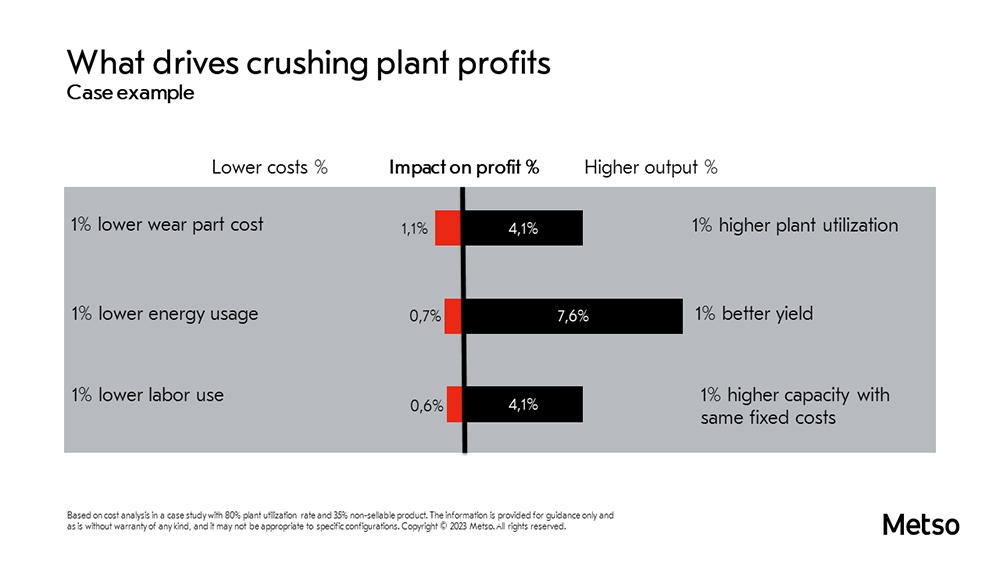

Here’s why it makes more sense to put more emphasis on improving crusher performance rather than focusing only on the cost of wears. In the case study mentioned earlier, we found out that when the cost of wear parts is reduced by 1%, it could have up to a 1.1% positive impact on the profits.

However, what happened if you could, not only impact the utilization rate, but also generate an increase in plant output? In the case study example, one percent higher plant utilization could bring up to 4.1% more profit; 1% more saleable product could mean up to 7.6% profit improvement; and 1% higher crushing capacity (no changes in fixed costs) — could mean up to 4.1% improvement in profit2.

Getting your crusher economy right

Metso has the same desire as you; getting your crusher to perform optimally so that you get the best possible return on your investment. Some of the factors Metso considers when designing different chamber configurations are:

- feed type,

- feed grading,

- desired product grading,

- crusher closed side setting,

- crusher operating speed.

For example, feed material that is either too small or too large can cause abnormal wear and shorten wearlife, leading to the need to change wears more often and resulting in a reduction in production time. In short, the better the chamber profile meets the requirements of the specific application, the better the crusher performance. To be able to identify the right chamber profile for your application requirements, these data points from your operation are needed.

Metso Chamber Expert service helps you to analyze and select the optimal profile from the crusher wears portfolio. Utilizing the proprietary ChamberPro simulation tool to select the optimal chamber geometry and crushing parameters, Chamber Expert service will help to optimize your production targets and the specific process.

Metso Chamber Expert service helps you to analyze and select the optimal profile from the crusher wears portfolio. Utilizing the proprietary ChamberPro simulation tool to select the optimal chamber geometry and crushing parameters, Chamber Expert service will help to optimize your production targets and the specific process.

Chamber Expert service delivers you multiple benefits. These include an optimally performing chamber and improved process performance, lower energy consumption, reduced environmental impact, cost efficiency without a major investment in new equipment, and verified wear part lifetime.

Author: Jukka Salovaara, Head of Business Development and Product Management, Aggregates Crusher Wears, Metso

Get in contact today about the Chamber Expert service: Chamber expert wear part optimization service - Metso

1 Metso Crushing and Screening Handbook 2023

2 Based on cost analysis in an example case study with 80% plant utilization rate and 35% non-sellable product. The information is provided for guidance only and as is without warranty of any kind, and it may not be appropriate to specific configurations.

Content produced in association with Metso