Terex claims to have created the ultimate smooth riding articulated dump truck following the launch of its new full suspension. Claire Symes reports

Advances in cab and seating designs have helped to significantly reduce vibration affecting the operators of articulated dump trucks (ADTs). Improvements to suspensions have also been made but most ADTs still feature solid beam axles across the front, leaving the cab and seat to absorb any shock.

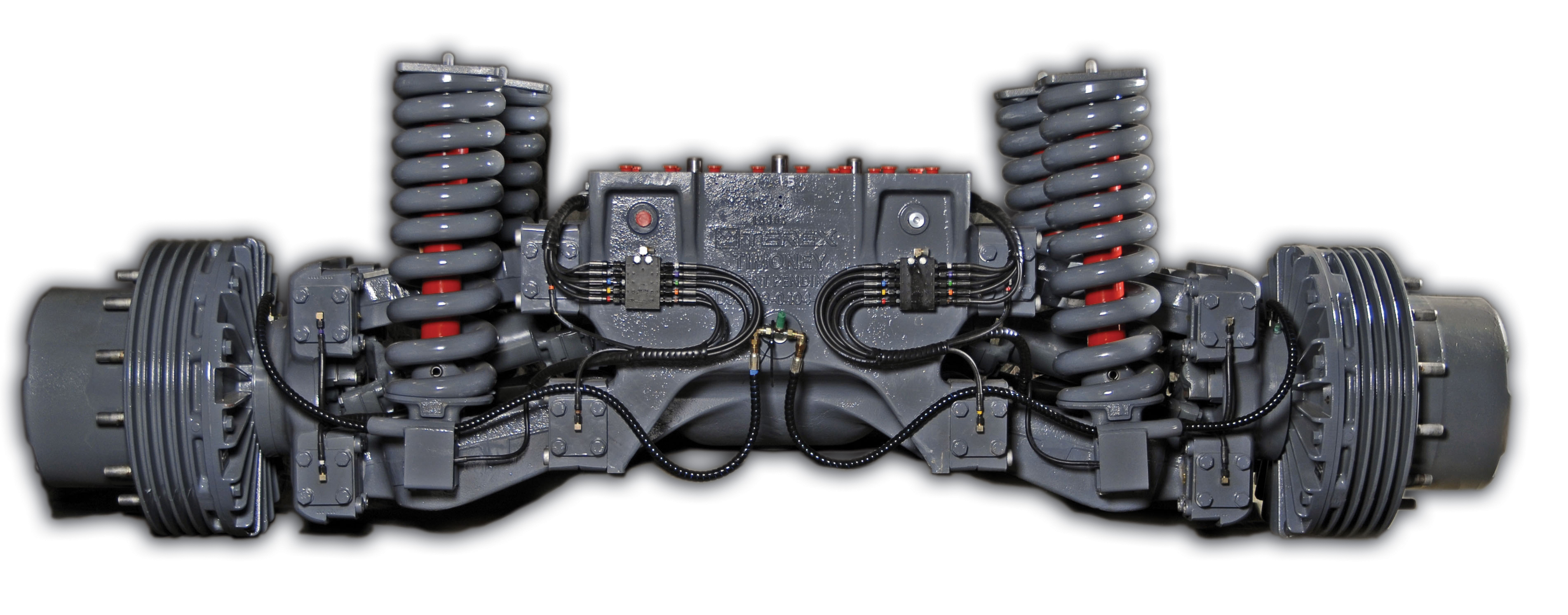

But Terex believed that the ride quality of ADTs could be further improved and started work on developing a new suspension system in 2003. The result is a fully independent front suspension - Terex claims this is a world first - that reduces vibration by 51% compared to previous models.

"Developments in engine and drive train technology for ADTs have advanced considerably over the last decade," said

The suspension system features dual rated coil springs with 210mm of travel, which Timony product manager Eoin Cashin said offer a simpler solution that struts. "The dual rating offers a softer suspension when travelling straight ahead but the spring stiffens on turning to reduce body roll," he explained.

The suspension's main pivot features double lift V seals, mounted back to back with a vent hole behind the seals and aluminium-bronze bushes.

"Most of the parts have been specially designed for the new suspension system but there are a number of specialist parts in the design, including Kone shock absorbers," said Cashin.

The prototype for the axle was tested for durability on a rig and put it through 1.8million cycles under 0 to 2G vertical loads, braking and scrub loading. "Some minor modifications were made to the design following the rig testing," said Cashin. "The real challenge with the suspension design was to fit the new technology into the space available, while keeping the design both cost effective and durable." On site testing of a TA30 fitted with the system was carried out at an open cast coal mine owned by Hoffman in Germany. According to Cashin, the testing showed that the machine offered better efficiency over the standard beam axle suspension.

Pre-production manufacture is being carried out at Timony's facilities in Ireland but it is expected that production will soon be taken in-house by Terex and carried out under licence.

From September this year, Terex's new suspension will be standard equipment on the TA30 and will be available as an option on the 23 and 25tonne capacity TA25 and TA27. According to Colver, the long term aim is to make the system standard fitment across Terex's ADT range. "Not only does the new suspension offer a better ride and improved efficiency, but with the addition of wet disc brakes as standard and other refinements, we have also been able to extend the service intervals on the TA30," said Colver.

According to Colver, interest in the new suspension system is high. He said that the machine on demonstration at Hillhead in June had already been sold to an earthworks contractor in Leicester, UK and was due to be delivered after the show closed.RSS