A new

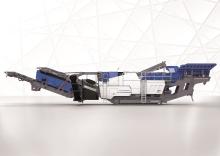

The track-driven impact crusher is used in a wide variety of recycling applications and also in natural stone.

At a quarry near Pappenheim in Bavaria, the machine has been used for crushing lime rock. With the screening unit and oversized grain recirculation feature, a defined final grain size of 0-45mm is produced, which can later be used as a substrate for road building.

“Here, it is particularly important that as much of the fine content as possible, in this case the large amount of lime, is removed from the charged material, otherwise there is a risk of the water not being able to drain as required through the substrate layer and causing damage mainly in winter as a result of frost,” says the

Wolfgang Schöberl from Eckl says: “A daily output of about 3,000tonnes of end material is no rare occurrence, and it achieves this with a consumption of 0.1litres per tonnne.

“Moreover, an additional grain size can also be produced very flexibly by swinging out the return conveyor. This is very quick and easy to do and we can then produce a grain size larger than 45mm, which can be used as oven stones or gabion material.”

According to Schöberl the new operating concept is also impressive with the machine being easy to operate and practically maintenance-free, but if required service is provided by the Wirtgen sales branch in Augsburg.

Uwe Herrmann, responsible for the sales and distribution of Kleemann plant systems at Wirtgen in Augsburg, says: “Everything simply has to be right. The customer needs the right machine with the right equipment for his/her application scenario or, in this instance, application scenarios. A certain amount of expertise is required even before a purchase is made. And the right service must follow.”