A new MDS-2000 drilling system from

To monitor and control drilled blast holes in a granite quarry in Vacamonte, Panama, the company has equipped an HCR-1200 EDII-type drilling device from FRD Furukawa Rock Drill with the drilling system in collaboration with B-B-S Bohrsysteme.

Since installation and training of the machine operators, the machine is now operating in two shifts.

“The system allows for efficient machine resource planning and exact drilling of the blast holes,” says Jose Alvarez De Soto, general director of FRD Latin America.

Moba says that with the MDS-2000, the drill holes can be made exactly parallel to each other to the desired depth and the preset angle. This facilitates controlled blasting with smooth brims, which makes quarry work safer. Faulty drill holes or redrilling is prevented, which then reduces time and cost.

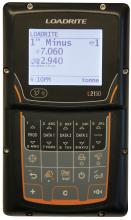

The MDS-2000 works with a two axis slope sensor with an angular range of ±60° as well as three rotary sensors. The sensors record all drilling data such as drill hole depth, drill angle and time per drilling and forward it to the controller, where it is processed and displayed.

With the integrated MTS-001 Telematics System, information can be exchanged between the drilling device and the office, and all drilling and machine data is sent to a server via a

This means the current status of the project and the machine can be called up from the office or anywhere else at any time.

All data appears right at the site for the machine operator on a display, specially designed for mobile applications.