From rock-face gravel through railway ballast and on to building rubble: when such a wide variety of materials are loaded on the machines, multi-talents are required from the crushing and screening equipment that is being used.

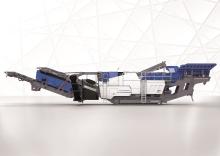

These requirements provided a highly suitable environment for the new Kleemann screen for coarse elements Mobiscreen MSS 802i EVO. In Germany, the first machine of the new design has been put to work at a quarry operated by Ernst Krebs at Neumünster in central Schleswig-Holstein. Ernst Krebs, located in the far north between Hamburg and Kiel, is a very diversified company. Owner Caren Krebs and her son André operate several gravel quarries and their portfolio includes demolition and recycling work, earthwork, road-building and also a transport and logistics section.

The company's machinery was to be extended in 2021 by a new screening plant. The plant had to be flexible and perform in the gravel quarry just as well as on the recycling site – which is not an easy task. Whereas sand and fine-grained material are processed in the gravel quarry, in the recycling of rubble and railway ballast Krebs processes almost everything. This includes, for example, topsoil which is often particularly cohesive. The screening plant therefore has to deal with stone material ranging from very fine to very coarse as well as with all degrees of contamination.

André Krebs took his request to his long-time contact partner at Wirtgen Germany, Henning Lüdtke. After hearing the task description, Lüdtke believed that this was an ideal application area for the new Kleemann Mobiscreen MSS 802i EVO screen for coarse elements whose strength is its high flexibility and productivity.

The problem: at the time, the machine was not yet available on the German market. But Lüdtke found an unconventional solution, offering André Krebs a pilot series model of the plant for coarse materials. An offer that Krebs accepted, stating: "Even though it was bit like buying a pig in a poke. There were hardly any documents on the product.

“In our gravel quarries and in recycling we have been using Kleemann machines for a long time with real conviction. I was therefore fully confident that this machine would also do a good job.”

Krebs adds that he was not disappointed. "Everything is so much quicker; set-up times are shorter and output is higher. All in all, it pays off.”

The flexibility begins with the large feed hopper. The hopper rear wall and the filling aids can be folded variably so that loading from different heights, from both sides and from the rear can proceed in an optimum manner. The screen surface change is comparatively easy even in the lower deck because the screen casing can be placed completely in a horizontal position. The screening parameters can be adjusted precisely and even conversion, for example from three to two final grain sizes, is uncomplicated.

Transport from one work site to another is also swift: the discharge conveyors can be folded in – without the disassembly of parts. Thanks to the stepless driving control, the plant can also be moved precisely into position.

Krebs says that one of the real challenges for the company is the gravel extraction process, with the side discharge conveyor for fine grain having a very tough job. “This is no problem for the new plant!" he adds.

After a few months of practical testing, the screen for coarse elements was able to demonstrate its qualities. "One of the real challenges for us is, for example, gravel extraction. We have to deal with a lot of sand with a relatively small proportion of stone. This means that the side discharge conveyor for fine grain has a real tough job. This is no problem for the new plant," says Krebs, adding that the company has already ordered a further plant.

Another advantage of the new plant is that the screen casing can be set more than 20% steeper than many other screens for coarse elements on the market. This guarantees a great cutting effect for the separation of fine material such as sand and a significantly higher output.

Also in Germany, a Kleemann cone crusher is proving itself in the production of railway ballast and high-grade chippings.

A company near Berlin is using the Mobicone MCO 90i EVO2 cone crusher for recycling and the production of crushed rock and high-grade chippings. Since summer 2021, the plant - the first of this type worldwide - has been recycling mainly railway ballast. A Mobiscreen MS 953 EVO screening plant operates downstream of the cone crusher.

High demands are placed on railway ballast because, in a high-quality ballast bed, the stones dig into one another with their sharp edges to form a stable base. The sharpness of the edges is therefore an essential quality criterion of the crushing procedure. Furthermore, only suitable material gives the track system the required elasticity and ensures the unrestricted downward flow of rainwater.

At the work site near Berlin, the two Kleemann plants mainly process pre-crushed and screen material. This includes large amounts of crushed rock, which is processed for reuse or is crushed to produce high-grade chippings. The tolerances for the grain sizes in railway ballast production are very tight. An important quality criterion is to observe these values, which is why the cone crusher is fitted with an oversize grain returning system. From the single-deck, post-screening unit of the Mobicone MCO 90i EVO2, the oversize grain can be transported via a return conveyor back to the feed hopper and therefore processed in a closed material loop. The large screening surface with optimised screen utilisation makes effective screening possible even for grain sizes below 20mm.

For separating other grain sizes, a screening plant Mobiscreen MS 953 EVO is positioned downstream of the cone crusher. The classifying screen has large screening surfaces, which guarantee a high throughput even with small final grain sizes. Thanks to the plant design and overall concept, these screening plants are ideal for coupling with the Kleemann crushers.

The complete process is optimised by line coupling of the machines: the interaction of crusher and screening plant is stabilised via an automatic control system. Although both machines work independently of one another, in case of malfunctions or overfilling they send signals to the upstream or downstream machine. The plant train is then switched off quickly and reliably. Among other things, this saves fuel and relieves the burden on personnel: there are no emissions at the upstream or downstream unit and, furthermore, a single person can operate the complete system.

A crusher from Finland-based Metso Outotec is also proving itself in a German deployment. Due to the unique properties of the local basalt and an increase in demand, RF Sand needed a powerful mobile primary crusher that can take on a challenge. To increase throughput and enable the feeding of large quantities of abrasive natural stone at once, they decided to go with a Metso Outotec Lokotrack LT120 mobile jaw crusher.

RF Sand is part of the Reinhard Group which dates back to 1927, when it was founded by the great-grandfather of today's managing directors Marco and Ralf Reinhard.

The basalt extracted from the Balduinstein open-cast mine has an extremely high bulk density, which is why it is suitable, among other things, for applications on the Rhine, Main and Moselle rivers for bank or slope stabilisation. Armourstones from the traditional plant are also supplied as wave breakers to the Dutch coast or to more distant regions.

Due to the unique properties of the local basalt, such as its high abrasion resistance, resilience and acid resistance, and the resulting increase in demand, it was decided to use a more powerful mobile primary crusher to increase throughput. After an intensive testing phase, the investment decision was taken in favour of a Metso Outotec LT120, which has been produced almost 1,000 times worldwide and has already proven itself in a wide range of applications.

Ralph Phlippen, MD at authorised Metso Outotec dealer Fischer-Jung Aufbereitungstechnik, commented: "To meet the desire for a significant increase in throughput and to enable the feeding of large quantities of abrasive natural stone at once, our recommendation clearly leaned toward the Lokotrack LT120 mobile jaw crusher.”

Fischer-Jung initially provided the jaw crusher to the open-cast basalt mine for testing purposes for a period of two months. This gave Marco Reinhard and his team, who rely exclusively on mobile processing plants within the site, the opportunity to test the LT120 in interaction with existing units such as the fine crusher and screening plant.

JCB Power Systems has won a contract to supply Stage V IPU engines to leading crushing and screening equipment manufacturer Powerscreen.

The partnership will see bespoke specification JCB 81kW and 97kW Stage V IPU engines power the latest models in Powerscreen’s Warrior and Chieftain screening ranges. Production of the new JCB-powered equipment began in August 2022, with the first models now in the market. This includes the Chieftain 1400, Warrior 1400X and Chieftain 2100X models, which have been flagships of the Powerscreen brand for over 20 years.

JCB Power Systems OEM engines sales and applications manager Jon McNulty said: “To be selected by a market-leading screener manufacturer such as Powerscreen is a fantastic achievement for JCB engines, and it is a testament to the capability and durability of our IPU models that they can excel in the arduous crushing and screening environment. Their proven performance in this type of application is seeing JCB Power Systems gain significant traction in this huge market.”