With an immense total length of 2,236km, National Route 1A is particularly heavily trafficked along the section between kilometre 16 (Lang Son) and kilometre 170 (Hanoi). The stretch, which is narrow, steep, and winding in some areas, is used by lorries, cars, countless scooters and even pedestrians. It was therefore high time the performance and safety of National Route 1A were improved.

Licogi 16 JSC (Licogi 16) – one of Vietnam’s largest construction companies with 20,000 employees and a firm foothold in almost all construction industry sectors – won a contract for a near 100km section of a 154km-long National Route 1A bottleneck relief/motorway upgrade project. To help fulfil its brief, Licogi 16 used a track-mounted Kleemann five-plant combination – three crushing and two screening plant – to process basalt, an immensely tough rock, for the new highway surface course.

Licogi 16’s highly dynamic civil engineering division is carrying out a number of road and bridge construction jobs and maintains close business relations with Vitrac, the Wirtgen Group’s dealer in Vietnam. This made the firm’s choice of premium Kleemann plant and technology an obvious one.

The Licogi 16 National Route 1A works are the first Vietnamese project for Kleemann crushers and screeners. As such, the models are attracting close attention nationally and across the rest of South-East Asia. Licogi 16’s Kleemann plant combination consists of an MC 110 Z EVO jaw crusher, an MCO 9 EVO cone crusher, an MS 703 EVO screening plant, an MCO 9 S EVO cone crusher and an MS 19 D screening plant.

In the quarry 40km south of Lang Son, the Licogi 16 team found itself facing two challenges: firstly, they needed to crush the hard and abrasive basalt and classify it into clean aggregate fractions. Secondly, they had to fulfil very high-quality requirements.

Armed with its new Kleemann plant combination, the Licogi 16 team was said to be able to meet the required project criteria with astonishing ease. The company discovered that the Kleemann crushing and screening plant takes care of everything almost completely autonomously once you know how to coordinate the machines. Kleemann’s Continuous Feed System (CFS) played a key role in making the work easier. In this case, the crushing plant in the first crushing stage, a Kleemann MC 110 Z EVO jaw crusher – only drew as much feed material into its crushing chamber as the entire line-coupled plant combination could process. This prevented overloads and, to the greatest possible extent, material blockages.

Electric is key when it comes to the cost-efficiency of Iceland’s largest crushing contractor Steypustöðin. At a quarry close to Reykjavik, Metso Outotec’s electrically operated Lokotracks are three to four times more cost-effective than the corresponding diesel-operated versions.

When compared to diesel operation, electric crushing achieves up to quadruple savings at the Hafnarfjörður quarry.

Steypustöðin is the market leader in crushing and concrete production in Iceland. Over the course of a year, the company’s two main quarries produce approximately half a million cubic metres of crushed stone, most of which is used at the company’s six concrete-mixing plants.

Steypustöðin now has a total of 20 Metso Outotec crushing and screening plants, ranging from a G1814 cone crusher to Barmac VSI (vertical shaft impact) crushers, LT series jaw and impact crushers, and ST series mobile screens. Of these, one Lokotrack LT120E jaw crusher and LT330D crushing and screen plant are fully electric.

“For us, the most important characteristics of crushing and screening plants are good mobility and reliability. The climate in Iceland being what it is, we can only crush stone when the weather allows it—and when it does, the crushers must operate without interruption,” says Hörður Pétursson, the managing director of the operation of Steypustöðin.

“We have been able to rely on Metso Outotec’s equipment – which is why we have remained loyal to the brand in terms of our crushing and screening equipment. Metso Outotec is an important partner for us. If any problems appear, we can resolve them with the support of Metso Outotec’s representative Vélafl,” Petursson says.

Steypustöðin has three crushing teams that work at the company’s two quarries as well as doing contract work all around Iceland. While travelling, they mostly produce road foundation materials.

The crushing conditions in Iceland are some of the most demanding in the world: humid feed can easily coat the surfaces of crushers and screens. Furthermore, the wind is often so strong that the paint is quickly sandblasted off the surfaces of working machines.

In 2014, Steypustöðin built a new 12-km power line to the Hafnarfjörður quarry close to Reykjavik just for crushing purposes. The electric Lokotracks were taken into use in 2017.

“Direct electric drive has proven to be the right solution, and the investment will quickly pay itself back. When compared to operating on diesel, the savings are triple or quadruple. The plant is also more reliable because there are far fewer parts to maintain,” says Sigurdur Sigurdsson, who is in charge of servicing.

“As an added bonus, there are less environmental emissions. Natural values are important to us; after all, tourism is currently the most important industry in Iceland, even before fishing.”

The production process at the Hafnarfjörður quarry has four stages. The blasted crushed stone is first loaded into an LT120E jaw crusher plant with a wheeled loader, and then from there it is transferred to an LT330D crushing and screen plant where a three-deck screen separates fines.

The third crushing stage to make the final product cube-shaped is handled by a Barmac B7150 VSI. Finally, all the concrete aggregates are washed in a separate washing plant.

Steypustöðin’s six concrete-mixing plants make concrete elements from the company’s raw materials. Loftorka, a company that Steypustöðin purchased in 2017, turns the concrete into an extensive construction-product portfolio.

“Our quarry workers really are actual superhumans: they are not afraid of coming to work when it is windy and snowing. They need a strong disposition to work a full day under conditions where the wind can knock over a passenger vehicle or an empty truck,” says Hörður Pétursson, praising his employees.

The exceptional conditions also cause extra work. All working machines must be modified to withstand the extreme conditions in Iceland. It is quite usual for the working day to start using hot water to wash off fines that have stuck to the equipment because of the humid sea air.

Due to the climate, Steypustöðin’s crushing days in winter are shorter: approximately eight hours from Monday to Friday. In the summer, when the sun shines all day round, the crushers are operated for at least twelve hours a day, also on Saturdays.

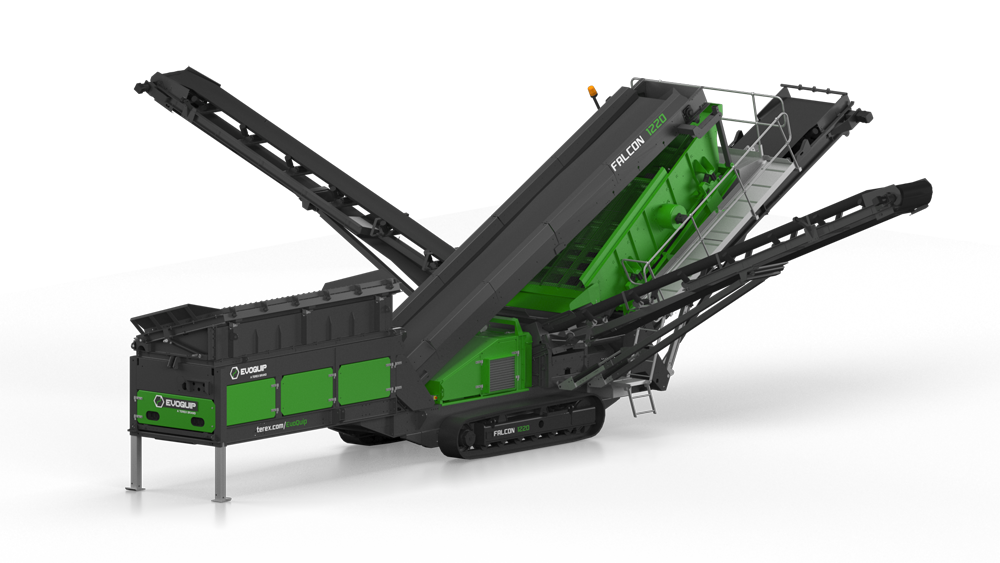

EvoQuip, a Terex Materials Processing brand, has added the Falcon range of finishing screens to its product portfolio.

The Falcon 1220 and Falcon 1230 offer a solution for scalping, screening, and stockpiling in self-contained units. Both models are available to order now and will be shipped to customers in early 2021.

Barry O’Hare, EvoQuip business line director, said: “We are confident that these highly aggressive finishing screens will open up new opportunities for EvoQuip customers globally.”

The Falcon range with its exceptional screen angle range provides an efficient classification of fines and is ideal for multiple applications and processing materials including sand and gravel, crushed stone, coal topsoil and demolition waste. In keeping with the EvoQuip model ethos, both the EvoQuip Falcon 1220 and Falcon 1230 are compact, easily transported machines and offer operators rapid set-up and tear-down times.

The Falcon 1220 features a 3.65m x 1.5m (12’ x5’) double-deck incline screen with remote tipping reject grid, hydraulic screen tensioning of the bottom deck and three on-board hydraulic folding conveyors as standard, with the option of adding the double-deck vibrating grid.

The screenbox on the Falcon 1230 features three inclined decks (top and middle deck: 3.66m x 1.52m (12’ x 5’), bottom deck 3.00m x 1.52m (10’ x 5’) giving a large screening area of 170ft² to provide efficient, high-capacity screening - even at small fractions. The fourth product conveyor has variable tilt and side slew to discharge material for recirculation and stockpiling accurately. The screenbox features quick wedge tensioning (top and middle deck), access holes and bottom-deck hydraulic tensioning system to reduce the time required for mesh changes.

The Falcons come with T-Link telemetry system fitted as standard, providing the customer with real-time information on their machine’s performance, meaning effective machine management and maximising uptime.

MDS International (MDS) is enjoying great success with its innovative drum-cleaner solution for its trommel range.

Jason Purllant, UK and EU sales manager for Co. Monaghan, Ireland-headquartered MDS, said he was with a customer recently showcasing the now year-old drum cleaner to a new prospective buyer. The prospective buyer told them that he had heard a lot about the product, but the proof of how good it was would be on his own material.

“He couldn’t get over how well it worked and how simple a solution it was,” said Purllant. “Like all the best solutions in life, the drum cleaner is so simple. We wonder ourselves why no one has come up with this solution before.”

Nearly all the trommels being sold by MDS are now being fitted with the innovative product.

Liam Murray, CEO of MDS, added: “The challenge for us was to make something that could withstand the rigours of metal and large rocks going into the drum whilst accurately meshing into the screening holes.”

Peter Scott recently used the MDS drum cleaner on his MDS M412 trommel at Scott Bros. in Teeside, north-east England. “Without the drum cleaner, we wouldn’t have been able to screen our wet and sticky recycled products. It gives us a competitive advantage in the market when others can’t produce clean aggregate material.

“It’s a foolproof solution to processing all our nasty overburden which would have normally been sent to landfill.”

Scott said Scott Bros. had previously tried processing the waste with a large screener from a leading OEM (original equipment manufacturer). He said it simply couldn’t handle the size of the aggregates they were trying to recover, and the stickiness of the soil and fines blinded over the screens within half an hour.

“I really couldn’t get over how well it cleaned up the aggregates in the muck-away and how easily it removed the fines from the rock. The feed product was the worst product we could find; we wanted to test the drum cleaner out to its full potential.”

For Scott Bros., the MDS M412 trommel fitted with the drum cleaner processed over 220 tonnes of waste per hour that would previously have been left. It provided aggregates to the crusher and fines to the wash plant when nothing else could. And it freed up space in the yard taken up by a previously “unprocessble” product that would have gone to landfill.

Another MDS customer, based in central England, who used the drum cleaner of their MDS trommel, said: “It’s an awesome bit of kit. I don’t often get excited by equipment, but this has changed everything.”

MDS says it has seen rapid growth in demand for trommels, particularly those fitted with the drum cleaner. As a result, the firm has recently appointed five new dealers across Europe.

Purllant continued: “The plan for next year is to grow our manufacturing capability by 40% just to keep up with our current demand.”

MDS is looking to hold an open day on a date to be fixed in May 2021 where existing and potential new customers will be invited to the company’s factory to see first-hand what MDS stands for and how the firm’s trommels and innovative drum cleaner can benefit their businesses.

The full MDS range features eight trommels: M412, M413 3-Split, M515, M518R Recycling, M615, M820, M820R Recycling, and M825. The firm also manufactures standard and heavy-duty apron feeders.