The aggregates event takes place at Nashville Music City Center, where Durex Products will exhibit at booth 1147.

The Luck, Wisconsin-based company says it offers numerous innovative urethane, rubber, and specialty wire screen media options, which allow customers to fine-tune production and increase tons per hour, while keeping products in spec and lowering operating costs.

Durex has offered premium screen media technologies since 1965, including its Livewire, Armor, Accuslot, and Vibraspan products. Wear liners and parts for aggregate equipment and screen accessories round out the company’s offerings.

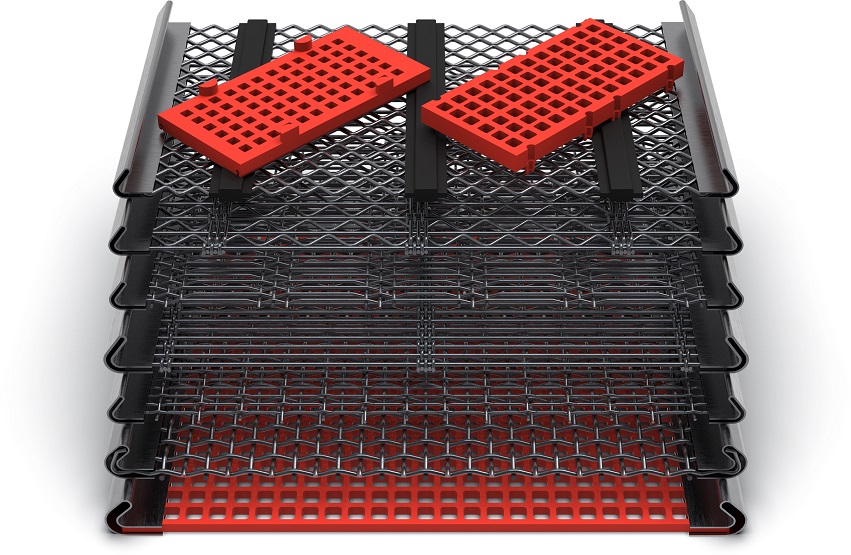

The company's modular urethane and rubber screen panels are available in modular snap-in, pin-style, knock-in, and bolt-in systems. These panels feature tapered openings that are wider at the bottom, which reduces plugging and increases throughput.

The woven and slotted wire screens are made of high-quality oil-tempered, stainless, or high-carbon steel. Woven-wire screen allows the use of lighter-gauge wire, while still providing excellent wear life. Long-slot triple-shoot screens are crimped to provide better screening accuracy and eliminate blinding and plugging.

Livewire screens are a self-cleaning-type screen, featuring molded rubber strips that hold its high-strength wires in place, providing better screening action and greater open area.

Accuslot screens are a self-cleaning-type screen that helps eliminate plugging and/or blinding, while minimizing the passing of slivers and chips.

Vibraspan screens are a self-cleaning-type screen featuring longitudinal slots for more open area, without sacrificing product size control.

Armor screens are a combination of high-grade woven-wire cloth with molded polyurethane coating, designed to increase throughput, as it reduces plugging and noise.

The Wear liners range includes magnetic, plug-weldable, and bolt-on liners for screen boxes, crusher mainframes, feed boxes, chutes, flumes, and discharge openings.

Wear parts include urethane and rubber, used in sizing and separating on screens, classifiers, dewatering screws, and various chutes and transfer areas.

Screen accessories include, but are not limited to, side-tension rails, J-bolts, U-bolts, donuts, stringers, and ferrules.