Screen media selection is an often-overlooked factor in mineral processing that can have a significant impact on overall efficiency. Though relatively cheap compared to the rest of the equipment in a quarry or mine, it could be argued that media has as much impact on productivity and material quality as the vibrating screen. It is important that operations give screen media as much buying consideration as they do the vibrating screen itself according to Lars Bräunling, director of product technology at MAJOR, which manufactures wire screens for the aggregates, mining and recycling industries

For this reason, Bräunling says that a number of factors should influence the choice of screen media.

“Certainly, cost is a consideration, but it shouldn’t be reduced to purchasing price versus wear life,” he says. “A full cost analysis needs to include labour cost for change-outs and cleaning, loss of production during downtime, media performance — tonnes produced, for example — and indirect factors like crusher relief.”

Bräunling adds that thinking only in terms of monetary value can be shortsighted and end up costing an operation more in the long run. The operating environment — including material characteristics and recurring screening problems — should also be considered. From there, look at different media types to find out what fits best, and learn proper installation and maintenance to ensure long term success.

Selecting the proper screen media for an application first involves examining the screening plant and any issues surrounding it. Bräunling recommends starting by taking a look at the material being processed to get an idea of what the media needs to stand up against. Consider the drop height, material size, abrasiveness, weight and volume. The more impact the material will have on the screen media, the higher durability that media should have, at least at the impact point. Abrasive material like granite calls for resistant screen media, such as polyurethane or high-vibration wire media. Likewise, top sizes of 254mm (10”) or larger demand a more durable screen, including options like double wire screens, perforated plate or rubber.

Operators should also take a look at the flow of material. “A visual check or belt cut of the crusher feed belt is an effective way to see if there is saleable rock being sent to the crusher,” Bräunling says. “This could be the result of carryover or because the deck capacity is exceeded. The solution may be adjusting the cut, improving capacity or fixing screening problems like blinding or pegging with alternative screen media.”

In addition to the deck itself, the pile of discarded screen media can be a good area to look for insight into screening problems. Bräunling says that operators should take note of things like broken wires, wear areas, pegging or blinding to pinpoint problems on their decks. Any of these can lead to material contamination and downtime, making them a significant cause for concern.

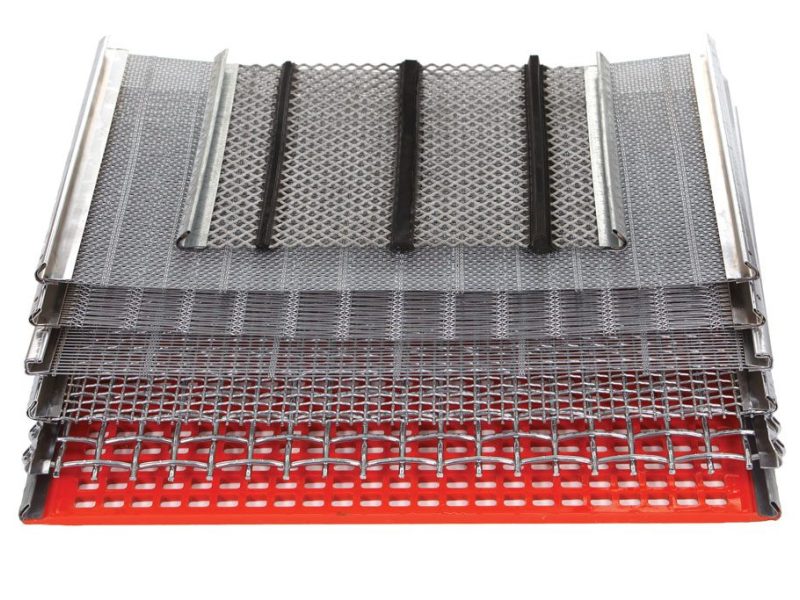

Depending on the operation, an hour of downtime could be expensive in terms of lost production, which makes choosing a screen media that maximizes uptime and efficiency even more critical. Perforated steel plate and heavy rubber panels are, almost by definition, the most durable options. Rubber can be effective for screening material with a top size larger than 12 inches or for openings bigger than four inches, but tends to be more susceptible to pegging.

Perforated plate is an acceptable option for applications requiring a durable screen media with a lot of open area, but is often noisier and heavier, which can cause issues. Both also typically have less open area than wire alternatives.

“Woven-wire cloth has been the traditional option for a long time for a reason,” says Bräunling. “It is relatively inexpensive and effective. But there are a number of advanced options available that offer more durability, throughput and versatility. And purchasing a traditional woven-wire design based solely on price may end up costing more in terms of wear life and more frequent change-outs.”

Synthetic modular media, such as polyurethane or rubber, is typically known for its long wear life and ability to reduce noise levels, but it isn’t without its own challenges. Bräunling says this type of media typically has less open area than wire screens, leading to decreased throughput. This, in turn, also reduces the capacity of bottom decks because the material takes longer to make its way down.

Both synthetic screen media and traditional woven wire are very rigid and rely on the vibrating screen to do most of the heavy lifting. The static movement of the screens limits vibration to 800 or 900 cycles per minute.

“In most cases, this does not hinder the screen media from achieving adequate production and throughput, but it is not fully using screening equipment, either,” Bräunling says. “And often it results in common issues, such as blinding and pegging.”

He adds that high-vibration screen media offers a wear-life compromise between synthetic and woven wire, and often provides the most performance benefits. The media features high-strength wire bonded by polyurethane or rubber strips to hold individual wires. The wires vibrate independently of one another — within opening size specifications — to amplify the screening process and increase throughput by as much as 40%.

Not all high-vibration screen media is the same. Most manufacturers do not customise the media specifically to each application to ensure optimum performance and wear resistance. When properly fitted to an application, Bräunling says that high-vibration screen media can amplify the work of the vibrating screen with vibrations of 6,000 to 10,000 cycles per minute — up to 13 times greater than traditional, rigid media options.

“There are inexpensive options for every style of screen media, but operations should hesitate before choosing them,” he says. “The lower price often comes with reduced performance and wear life as a result of poor quality with the material, weaving, trimming and hooking process for wire screens or, similarly, poor manufacturing and material with other styles of screen media.”

He adds that operators should start off correctly with proper installation and then monitor to ensure the longest possible wear life. They should inspect the condition of all components that come in contact with the screen, and replace if necessary.

“Selecting the best screen media involves taking a look at the big picture,” Bräunling states. “While not required, an operation can expedite the decision process with experience-backed recommendations from a screen-media OEM [original equipment manufacturer] or dealer. With infrastructure on the rise, the potential for fewer screening problems, increased uptime and more profit flowing over the screen makes the whole process worthwhile.”

MAJOR launched three new products at the recent ConExpo show in Las Vegas that are aimed at maximising the productivity and efficiency of its popular FLEX-MAT range.

The FLEX-MAT ID-Enabled system has been designed to track and store screen-media data such as panel dimensions and customer-defined details to offer users information at their fingertips for simple reorders.

The FLEX-MAT Sensor is said to be a valuable and easy-to-operate vibration data-measurement tool with which to review results and fine-tune screen machines without shutting down the equipment.

MAJOR has also launched a new smartphone app to give customers up-to-date information and access to advanced digital tools. The MAJOR App is available for aggregates and mining producers and MAJOR dealers, with customisations for each. It integrates with new MAJOR technologies, including the company’s FLEX-MAT ID-Enabled and the FLEX-MAT Sensor.

Also at ConExpo Durex promoted a number of screen-media options for the aggregates and mining sectors including the Accuslot, Armor and Livewire screens.

Accuslot Wire Cloth is designed to provide the accuracy of square openings with the production efficiency and cleaning ability of long-slot wire cloth.

Durex says that Accuslot screens help eliminate plugging and/or blinding, while minimising the passing of slivers. Clusters of wires can be spaced to match bucker bars. The screen media is built for processing crushed stone, sand and gravel and materials that have high moisture content.

Durex says its Armor screens protect an operation with a long wear life, high open area and reduced noise. The screen is a combination of high-grade wire cloth and a moulded coating of premium polyurethane. Durex states that this combination of technologies creates screens that have a much higher open area than conventional polyurethane screens and much longer wear life than wire screens.

The Livewire Wire Cloth is designed to boost productivity by reducing costly blinding and pegging problems while also delivering superior wear life. Livewire screens are a hybrid-type screen and available in four different opening styles for maximum output.

US-based Samscreen supplies the KleenSkreen finger deck replacement screen system. The system is made for difficult-to-screen materials where blinding, clogging and pegging cause problems with traditional screening media. The KleenSkreen can be retrofitted to existing portable and stationary screening plants, which the company says provides a viable and economical choice of not having to purchase a new piece of equipment similar to a StarScreen or trommel.