Aggregate washing is helping quarries worldwide to improve the quality of end products and offer added value, and in some cases overcome legal rulings.

Driving greater use of washing equipment are stricter aggregates specifications and the need to make the best use of all material that is extracted from quarries while keeping an eye on the environment.

To meet these demands the latest technologies also offer operators the opportunity to make sure this growth does not make a major impact on water consumption or energy.

For example, MAAD Minerals & Mines, based near Mumbai, India, installed a new washing plant from CDE, which is producing manufactured sands from basalt.

Last year a government ban on mining natural sand from rivers in Mumbai in an effort to protect the natural environment was challenged, but upheld in the Mumbai High Court. The decision had a significant impact on the construction industry in the region.

It is felt that this ban on river sand mining is indicative of a wider trend throughout India, and indeed this is being mirrored throughout the world.

This presents big opportunities for systems which can deliver washed manufactured sands as a natural sand substitute.

Whether the natural sand shortage comes from a ban on river sand mining or a shortage of natural sand within a particular area, these systems offer operators a proven mechanism to increase the efficiency of their operations while at the same time maintaining the highest levels of product quality, says CDE.

The processing of crushed rock, quarry dust and scalpings to produce sand products with a range of different applications is an area where CDE have developed experience in recent years.

“Initially our focus was on the washing of quarry dust, stockpiles of what was perceived to be a waste product, and the conversion of this material to washed sand primarily used as a natural sand substitute in the manufacture of concrete” explains Manish Bhartia, managing director at

“These systems were first introduced by CDE over a decade ago in Ireland and the UK and we now have similar plants producing manufactured sands from crushed rock material throughout Europe and Africa as well as in India.”

According to Bhartia these systems cover a wide range of different rock types including limestone, basalt, granite, gabbro and tillite.

In the Mumbai area material has to be imported from neighbouring states not facing the same shortages, thus increasing transport costs for those manufacturing building sands for concrete, plastering and mortar.

“When you take the ban on this practice in the wider context of a shortage of alternative natural sand resources in the area, the construction industry was faced with a major problem,” says Chiranjib Banerjee, sales manager with CDE Asia.

Faced with this changing situation MAAD Mines & Minerals looked at alternatives to allow it to continue producing construction sands it required for its commercial building activities.

“Crushing alone would not produce a manufactured or ‘engineered’ sand of sufficient quality due to the high proportion of minus 150 micron material in the feed material,” says Banerjee.

MAAD Mines & Minerals was producing a crushed basalt product from its vertical shaft impactor (VSI), and this was subsequently sent to a dry screening phase and the underflow from the screen is delivered to the CDE manufactured sands washing plant.

The EvoWash system supplied by CDE will for the vast majority of production time produce concrete sand (coarse) and plastering sand (fine), but it can also produce a single plastering sand or concrete sand in larger quantities as required by the customer.

The washed sand product is typically less than 12% moisture content (by weight) which ensures it is suitable for use immediately.

“While the ban caused much initial concern in the industry it has forced the industry to look at how it can ensure supply of the required material from a sustainable source. When you evaluate the production of manufactured sands from crushed rock the environmental benefits are there for all to see. Elimination of the risk of damage to our natural environment caused by the mining of sand from riverbeds is the obvious advantage,” says Manish Bhartia.

According to CDE the waste-water treatment process, involving its AquaCycle tank, reduced the volume of fresh water to feed the washing plant by over 90%, a step that meant the plant requires only 22m³ of fresh water/hour. Without the addition of the AquaCycle thickener the figure would be 220m³/hour.

Other major companies are also grasping the opportunities that high quality washing equipment can offer and are introducing new products in order for operators to maximise the use of their products.

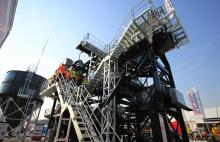

Announcing its plans to launch a new model at the upcoming

The plant can produce three aggregates and two types of sand.

The Aggresand plant’s design achieves this by providing a throughput capacity of 250tonnes/hour as well as having quick set-up time allowing the plant to be erected in one day. It fits into six shipping containers and the quick set-up time is also achieved through essential plug and play plumbing/pipework and electrical wiring.

Following the new plant announcement at

“Our engineers have been working on finalising design and specification of the new larger Aggresand 206 model to give our customers the same benefits as the Aggresand 165 system, but with even more capacity. We’re looking forward to meeting our customers and showing them how this new system will help their businesses,” says Sean Loughran, director of TWS.

The company says that the Aggresand 206 model shares all the modular features of the Aggresand 165 model including ease of transportation, rapid set-up time, pre-wired and pre-plumbed and HMI control system, which have been delivering efficient, productive performance for current owners.

The Aggresand 206 utilises the well-proven Terex 20feet x 6feet inclined rinser screen and will be available in two or three-deck options. It is directed at the larger producer who wants to increase the tonnage up to a maximum of 400tonnes/hour.

Indeed, TWS hosted a US premiere of its Aggresand at the Carolina Sunrock facility in Kittrell, North Carolina, where TWS worked with Mid-Atlantic distributor,

“This is the first machine of its kind in this market and the interest has been phenomenal. The event has proved to be a real success and we are already witnessing increased activity in this marketplace,” says Loughran.

The Aggresand plant showcased at Kittrell featured a 200tonnes/hour twin sand plant compared to the first Aggresand plant launched in Ireland, which had 120tonnes/hour twin sand plants. TWS can offer two sand plant options, 120tph or 200tph, dependent on the customer’s application and the sand to stone ratio.

The local geology of Sunrock Kittrell Quarry is granite, which made the demonstration more significant, since high wear issues are more prevalent in this situation. Poly screens were opted for, in place of the typical woven wire screen mesh.

“The US premiere of the Aggresand wash plant proved to be another successful showcase. Reaction to the new plant was exceptional and we received immediate orders as a result,” says Elaine Donaghy, marketing manager of TWS.

Garry Stewart, applications engineer with TWS, says: “The market is really embracing the Aggesand concept with extensive orders following the [Conexpo] show. Feedback from customers suggests that acquiring planning for these modular set-ups is easier compared to large static installations. The rapid set-up time, high levels of serviceability and the advanced control system are also proving major hits with our customers.”