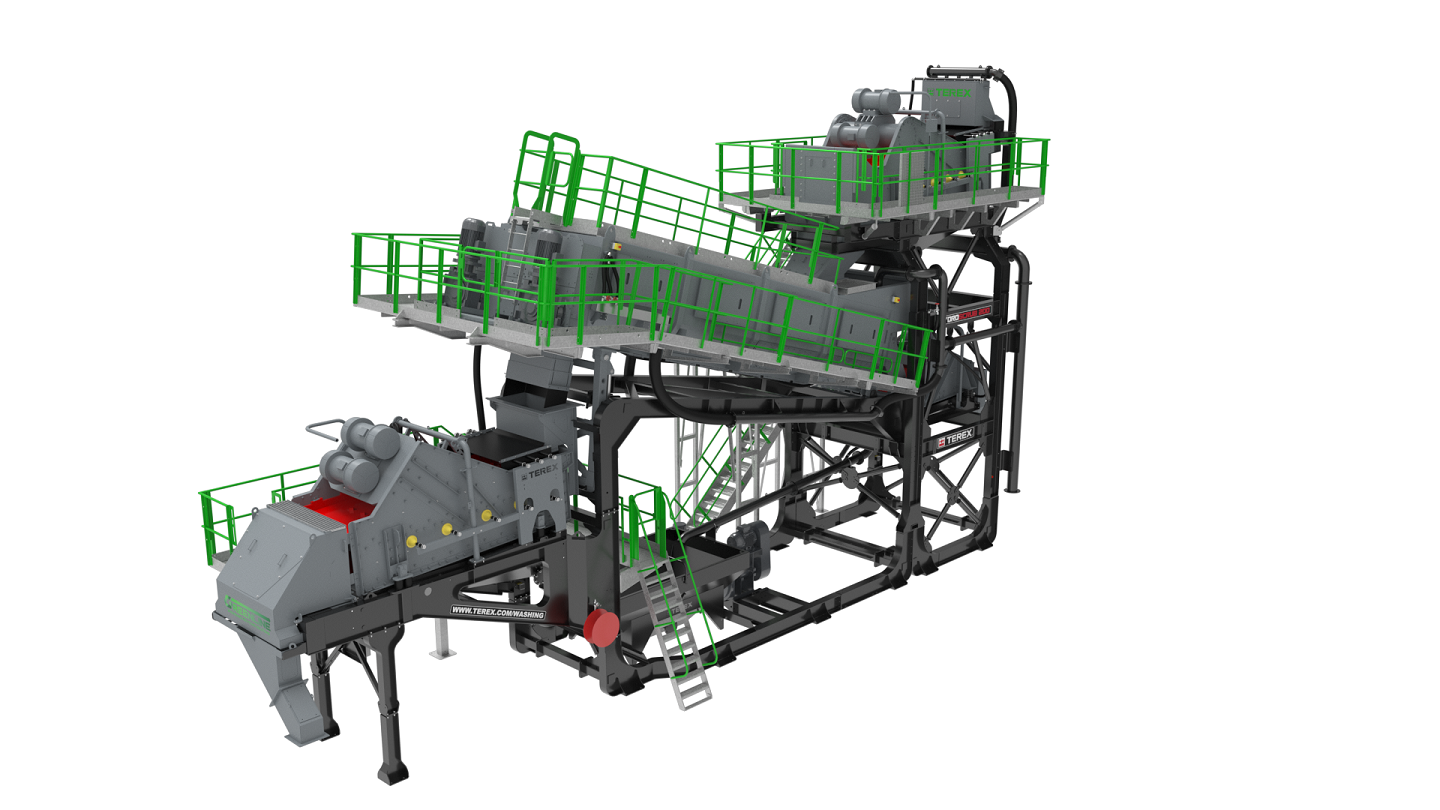

Described as TWS's "most versatile machine to date", and the end result of a two-year research and development project, the HydroScrub 200 wash plant uses the core principals of a high-performance log-washer with new features that offer dynamic adjustment and control, ensuring a flexibility that enables the customer to adjust parameters to optimise performance and suit various types of feed material.

Comprising of hydro floatation water injection, integrated pre and post screens, a high-volume trash removal screen, and single-pass processing for various feed materials, the HydroScrub 200 is said to be ideal for wash recycling applications. These can range from construction and demolition (C&D) muck away applications—where the challenge is liberating the valuable aggregates and light organics from tough to break down fines and insoluble clay—to 'high volume lights' applications, where the level of attrition required to clean aggregates is less, but high volumes demand more water to create the hydro separation required to float these off effectively.

Barry McMenamin, business line director - Terex Washing Systems, said: "We recognise that not only is there a huge growth in the wash recycling sector, but there is ever-increasing diversity in the range of materials end-users need to wash. The HydroScrub 200 offers the convenience of having one machine that can be easily adjusted to process different feed materials and provides opportunities for expansion in the range of customers you can provide a service for and expansion in terms of the volume of material they can process. It is the epitome of what we strive to offer through our Greenline range of products: balanced, end-to-end processing systems that enable our customers to wash wisely."

The HydroScrub 200 was officially unveiled on Tuesday 17 November at a live launch webinar that took viewers through critical features of the product and how it efficiently caters for various applications, allowing you to wash more and waste less.