Off-highway diesel engine giant

“Having a dual-certified Stage V/Tier 4 Final engine simplifies OEM machine design as the same engine can be used in the highly-regulated EU and U.S., so managing inventory is easier,” said David Nicoll, Perkins global marketing director. “The Perkins 2806J-E18TTA compliments the existing 2806D-E18TTA which is designed for use in lesser regulated countries and expands on our worldwide engine platform offering.”

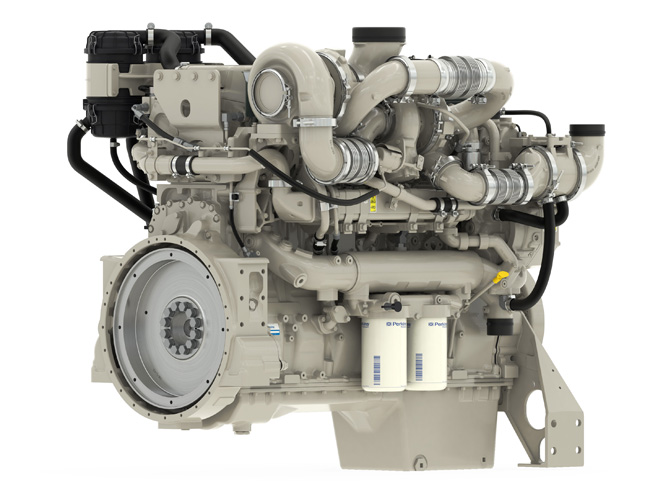

The new 2806J-E18TTA uses the same robust mechanical electronic unit injector (MEUI) fuel system found in the 2806D-E18TTA. The series twin turbos help to achieve a powerful 597kW at 1800rpm and produce 3710Nm of class-leading torque. A 563kW rating is also available.

The engine uses a maintenance-free diesel oxidation catalyst (DOC) aftertreatment to meet the emission standards – the ideal solution for engines in the 560-600kW range. There are no coolant, fuel or electrical connections which help simplify installation, and the absence of selective catalytic reduction (SCR) means there is no need for diesel exhaust fluid (DEF)—thus eliminating the DEF tank and reducing total package size and helping to minimise the cost of operation for the life of the machine.

“Today’s OEMs pack more components into less space than ever before and flexible installation options help them do that. The design of the 2806J-E18TTA allows OEMs to remotely mount a single can DOC, providing that installation flexibility,” Nicoll added.

Pekins says the optional engine-mounted aftertreatment (EMAT) eliminates the need to design and test special bracketry since the engine and aftertreatment can arrive as a single unit that is ready to be installed. The simplification of both installation design and assembly during manufacture is, says the off-highway diesel engine heavyweight, exactly the kind of solution many OEMs enjoy, as it allows them to focus on what they do best and continue to grow their business.