A UCLA (The University of California, Los Angeles) research team has received a two-year, $2 million grant from the U.S. Department of Energy to support the development of a process that can convert carbon dioxide emissions into construction materials.

According to a recent report on ConstructionDive, the team has also won an additional $905,000 from UCLA discretionary funds and industry partners. This will: "Advance research into capturing carbon dioxide from gas as it exits power plants, cement plants and other producers of carbon dioxide, reducing emissions.

"The process also cuts down on the use of traditional cement.

"The research team is led by Gaurav Sant, a professor at the UCLA Samueli School of Engineering, who invented CO2Concrete, a form of concrete that is made in part from carbon dioxide emissions.

"Sant, who is also the director of UCLA’s Institute for Carbon Management, said the product will have a carbon footprint 50% to 70% lower than that of regular concrete used in construction.

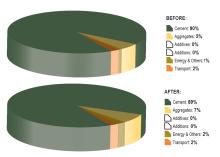

"The production of cement results in more than 8% of annual man-made carbon dioxide emissions.

"Similar to traditional concrete, the UCLA team's product is a mixture of a cementing agent, sand, stone, water and chemical additives.

"However with CO2Concrete, unlike traditional Portland cement-based concrete, the researchers have achieved cementation by the use of calcium hydroxide, which absorbs carbon dioxide from waste gas to form limestone.

"Sant likened it to the same type of structural cementation seen in seashells.

'We achieve such cementation in a matter of hours while being able to use a wide range of flue gases, and without the need for a carbon capture step,' he said.

"CO2Concrete offers a functional replacement to traditional concrete which offers similar performance at a similar price," the ConstructionDive report concludes.