Despite being disrupted by flooding due to heavy rain, the 11th edition of Excon staged by the Confederation of Indian Industry (CII) at the Bangalore International Exhibition Centre (BIEC) in Bangalore, southern India, demonstrated why it remains South Asia’s largest construction, quarrying and mining equipment exhibition. Joining almost 50,000 visitors and a varied cast of leading Indian OEMs, were around 100 notable OEMs from countries including the US, UK, Germany, Italy, UAE, South Korea, Czech Republic, Singapore, and Sri Lanka.

India’s Union Minister of Road Transport and Highways, Nitin Gadkari, has been urging Indian construction and quarrying equipment manufacturers to develop engines powered by alternative fuels like biodiesel, ethanol and electrification.

Given this, the state-of-the-art equipment solutions for extraction, mineral processing, loading and hauling on show in Bangalore 17-21 May 2022 included electric and diesel-electric hybrid-powered units capable of significantly reducing operating costs, making Indian construction and quarrying business owners more money, while also adhering to strict new lower emissions legislation.

Given this, the state-of-the-art equipment solutions for extraction, mineral processing, loading and hauling on show in Bangalore 17-21 May 2022 included electric and diesel-electric hybrid-powered units capable of significantly reducing operating costs, making Indian construction and quarrying business owners more money, while also adhering to strict new lower emissions legislation.

JCB India introduced the construction industry’s first fully electric excavator, the JCB 19C-1E. The 19C -1E is a zero-emission machine. Four lithium-ion batteries power the machine for a full day on a single charge. The OEM also launched its 22-ton hydraulic excavator on the NXT platform, specially designed for Indian applications. JCB’s natural gas genset, the G 125 NG, was also launched.

Deepak Shetty, CEO & managing director, JCB India said: “The JCB 19C-1E is the [construction] industry’s first fully electric excavator in India and is integral to JCB India’s ‘Road to Zero’ initiative, a programme, that we have been working on for the past few years. The machine has been tested extensively and has various built-in features that enhance safety and performance. With zero emissions and low noise, this new machine will be ideal for infrastructure development in urban areas and indoor jobs.”

Shetty continued: “We have taken a bold step of launching a natural gas-powered generator set that significantly reduces emissions. This range will be manufactured in India catering to the domestic market. The product will also be exported.”

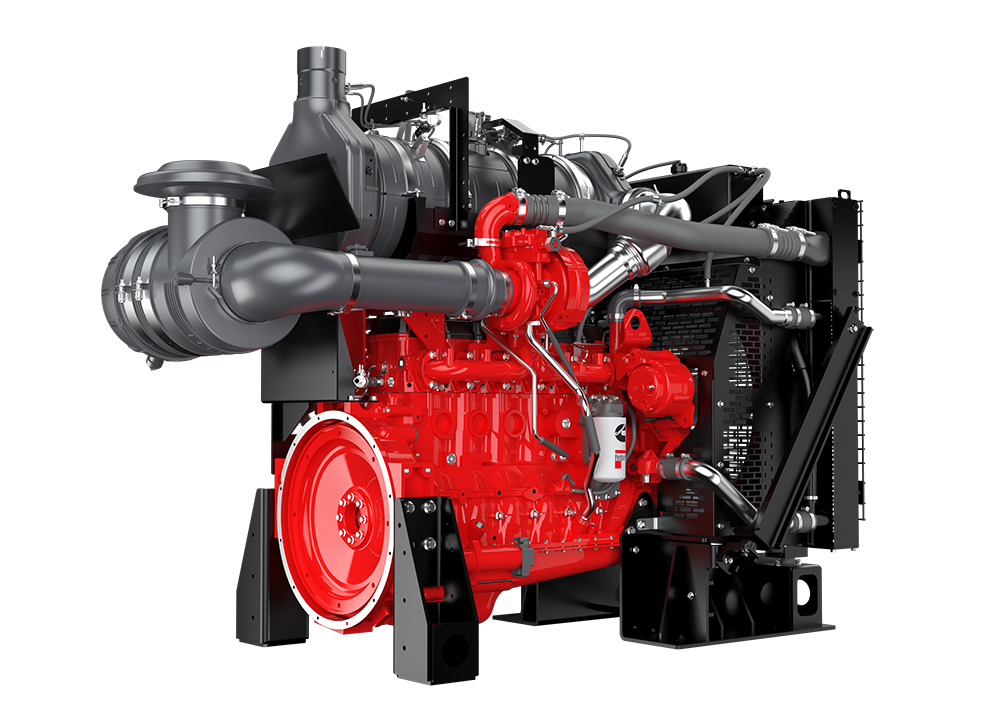

Cummins India celebrated 60 years of its presence in India by exhibiting its cutting-edge solutions for the construction equipment industry.

Cummins showcased its B4.5 (121 to 173hp) & B6.7 (173 to 260hp) engines, which are compliant with CEV BSIV regulations. These products are capable and scalable to the next emission level of CEV BS V and CEMM BS IV/V. Cummins' joint venture partners, Valvoline Cummins and Fleetguard Filtrum, also displayed their products.

B4.5 CEV BSIV units are suitable for soil compactor, 14-20-ton excavator, three-and-a-half-ton wheeled loader, and paver and motor grader applications. This engine is said to provide best-in-class fluid economy as compared to six-cylinder engines and has covered more than 18,000 hours of test cell and field validation in India.

The B6.7 is Cummins' biggest-selling global product. It is most suitable for motor grader, five-tonne wheeled loaders, 25-35-tonne excavator, crane, and harvester applications. This engine provides best-in-class performance, reliability, and lowest total cost of operation (TCO) in this power range. Cummins has sold more than 90,000 of these engines meeting advanced emissions.

Speaking about Cummins' participation at CII Excon, Anjali Pandey, Engine Business and Components business leader, Cummins India, said: "Tough terrains demand tougher equipment, and no one makes tougher construction engine systems than Cummins. Our construction engines are durable and reliable, producing more responsive power delivery with minimal maintenance costs. Thus, translating to maximum uptime and best TCO for our customers.”

Cummins in India provides leading aftermarket support and has an extensive service support network that offers a complete range of service needs such as engine health checks, maintenance services, repair services, and hassle-free Cummins Warranty administration.

Tata Hitachi displayed its newly launched CEV-IV emission-compliant, Shinrai backhoe loaders and the TL340 H Prime series hydrostatic wheeled loader. The company also launched the five-ton ZW225 wheeled loader and the new NX 30 mini excavator. Also displayed were the EX and Zaxis series of hydraulic excavators.

Komatsu India, Larsen & Toubro (L&T) and Scania India displayed a new range of biofuel-compatible equipment. This included the Komatsu PC 205-10 MO and Komatsu PC 500LR-10 R hydraulic excavators. Arvind Garg, executive vice president and head of L&T’s Construction & Mining Machinery said: “Komatsu has now introduced a new mining equipment fleet compatible with biofuel, which is an important initiative and can lead towards significant reductions in carbon footprint. The Indian mining and mineral processing industry is growing at a healthy pace and, as a responsible stakeholder, we are committed towards introducing innovative and environmentally friendly solutions in India.”

Garg continued: “The Komatsu Earthwork Master PC 205 10MO hydraulic excavator is specially built for the Indian market. It offers longer duty cycles, unmatched fuel efficiency, and low initial and maintenance costs. The PC 500LC-10R hydraulic excavator is the first of its kind from Komatsu in the 50-ton class. It is ideal for the mid-mining segment and works very well handling overburden removal in coal mines.” Komatsu machines are equipped with KOMTRAX tracking systems. This enables the users to monitor the equipment’s health for increased efficiency.

L&T also showcased a variety of manufactured sand plants and crushing solutions, and Scania India showcased its latest powerful G500 heavy, rigid dump truck in the L&T pavilion. With its novel modular system, the G500 is said to deliver high levels of productivity. The truck is manufactured by Scania Commercial Vehicles India at its Nasarpur site in Karnataka, South India.

Indian off-highway tyre manufacturing major BKT exhibited tyres for the mining and construction equipment customers, including the new giant EARTHMAX SR 468 TL. The latest addition to the EARTHMAX family, the 57-inch mining-machine-suited tyre features an all-steel radial structure, providing greater casing resistance. The tyre comes with special tread design and compound to limit heat generation and resistance to cuts. Also on display was the 45/65R45 EARTHMAX SR 53TL, an all-steel radial tyre with cut-resistant compounds designed for large wheeled loaders operating in rocky conditions.

JK Tyre, & Industries, an India off-road equipment tyre major, showcased its range including 45/65 58 PR VEM 63 L5 premium heavy-duty tyres for wheeled loaders, to support extra payloads, and the 12.00-24 HARD ROCK CHAMPION 20 PR E4, featuring high tread depth for better protection and traction for rigid dump trucks. The company also launched 16.00-25 VEM 045 44 PR E3 TT tyres to meet the increased load per tyre for tippers with higher payloads.

V.K. Misra, technical director, JK Tyre & Industries said: “Our new premium OTR tyre collection is created with advanced technology and is designed to deliver increased mileage and exceptional traction in most demanding situations. The tyres also deliver longer service life, equipment stability with cut-resistant compounds. JK Tyres has nine manufacturing facilities in India and three in Mexico, which collectively produce 32 million tyres annually.”

Schwing Stetter India launched the ZL 33FV (CEV-IV) and ZL 55GV(CEV-IV) wheeled loaders, and the XE 38U and XE 215-I LC excavators, among other products.

V.G.Saktikumar, the company’s managing director, said: “ Over the years, we have observed the rising need to become cost-effective for customers. We have partnered with Indian engine manufacturers Kirloskar and Mahindra for biodiesel solutions for the CE-IV engines. This will extensively assist in reducing the total cost of ownership of the product for the customers.”

Schwing Stetter India recently inaugurated its global manufacturing hub, built at a cost of INR 350 cores at Cheyyar in Tamil Nadu, South India. The state-of-the-art, 50,000m² integrated facility manufactures boom pumps, self-loading concrete mixers, shotcrete pumps, excavators, wheeled loaders, and motor graders for both the domestic and export market. The company will continue to invest in the facility for the next couple of years.

Volvo CE India displayed its new EC 300DL block-handler crawler excavator. Dimitrov Krishnan, head of Volvo CE India, said: “The crawler excavator is custom-built. It is armed with a heavy-duty lower frame and toughened undercarriage and is powered by Volvo D7 engine. The excavator is designed to deliver best-in-class productivity with lower operating costs and overall comfort and safety.”

CDE Asia exhibited its new Combo Alpha Smart manufactured sand plant. Manish Bhartiya, the company’s managing director, said: “Alpha Smart is a patented invention that converts crushed dust into manufactured sand in various industry grades. It features a cutting-edge technology that cleans, grades and recycles the water on a single mobile chassis unit and produces 120 tons per hour of washed, manufactured sand. Combo Alpha and its smart variants assure highest product recovery with an eye on sustainability.”

Sany India launched a range of biofuel-powered excavators and biofuel-compatible rigid dump trucks. “With steep hikes in diesel prices, demand for cheaper biofuel and base oil is rising,” said Deepak Garg, managing director of Sany Heavy Industries India & Southeast Asia. “With the Indian Government notifying that unblended biodiesel will attract an additional surcharge, we have worked with different engine manufacturers to make use of biodiesel to make excavator- and RDT-owning and operating costs competitive.”

The new SY225C-10HD GENe Series excavator from Sany India is especially developed for the 22-ton premium Indian market segment. According to Garg, this is an energy-efficient machine that is 8% more productive and 11% more fuel-efficient as compared to other 22-ton-class unit options. Fellow new range model the SY260C-10HD is a 26-ton class new generation hydraulic excavator that comes with a six-cylinder CRDI engine.

Sany India also unveiled the SY240C-9HD, a 24.4-ton GraMa excavator for marble and granite applications. Dheeraj Panda, chief operating officer (sales, marketing & customer support), Sany Heavy Industries India, said: “The excavator is equipped with brand new features like an ultra-heavy-duty track chain, robust scoop bucket to handle granite and marble blocks, and a power-boost hydraulic system.” The same features, plus long drain service intervals, are included on Sany India’s also new 37.5-ton SY390C-10HD GraMa large excavator.

Volvo Trucks India had a notable presence with its Volvo FMX 500 off-road rigid dump truck (RDT) and Volvo FM 420 8x4, 23m³ body construction tipper truck. “Both trucks are designed to provide the highest levels of productivity, fuel efficiency, combining unmatched safety and driver’s comfort. The enhanced Volvo Connect Telematics aims to deliver the highest levels of uptime and connectivity to our customers,” said B. Dinakar, executive vice-president, Volvo Trucks India.

Aimed at mining customers, the Volvo FMX 500 8x4 tipper truck comes with a body builder module, that prevents the truck from exceeding 5km-per-hour speed when the dump body is in raised position, thus preventing accidents. “The Volvo Dynamic Steering ensures that the truck is stable even while carrying heavier payloads,” added Dinakar.

SDLG India displayed its new L series seven-ton L975F and five-ton L958H wheeled loaders. Surat Mehta, head of SDLG’s India business, said: “The seven-ton wheeled loader is being positioned to strengthen our offerings in the higher capacity segment which is growing in India. The loader is highly suitable for 300-tonnes-per-hour-plus crushing plants. The L 975F can be used for arranging stockpiles, giving feed materials to the crushing plants, loading rigid dump trucks, and for transporting finished aggregates. The five-ton L958H wheeled loader will be highly suitable for tunnel construction projects with the side discharge bucket arrangement. The wheeled loaders come with advanced BSIV engines delivering higher levels of fuel efficiency and improved hydraulics for better loading.”

Bonfiglioli India showed its advanced gears and drives for tracked equipment, ranging from 1.5 to 1,500 tons across a variety of mining and material-handling models. Kennady V Kaipally, Bonfiglioli India’s manager, said: “We are an integrated solutions provider. However, the key segment which holds business potential for us in India is mineral processing, particularly tracked and stationary crushing plants and excavators. The segment is witnessing rapid growth due the surge in road construction projects in India.”

Stefano Baldi, global sales director, Bonfiglioli Riduttori, added: “There is growing demand in India for solutions for higher productivity and low operating costs. Bonfiglioli has the requisite expertise of working with top OEMs to provide the required integrated solutions. Our electronic and hydraulic features integrated in a machine’s mechanical transmission system provide online feedback to equipment owners and operators.”

Massimo Palomba, sector manager E-Mobility at Bonfiglioli Riduttori, said: “Our focus is also on providing integrated solutions with lesser carbon footprint. There is growing customer need for hybrid crushing and screening plant and road construction equipment. Taking cognisance of this, we are working on electric-drive systems and electric-motor drop boxes. We will look to introduce the products in India in the near future.”

Indian crushing and screening equipment manufacturer Proman displayed its dry classifier along with its stationary and mobile crushing plants. “There is rising demand for high-quality concrete and plaster sand in India. Our Pro Dry Classifiers can be used optimally by the quarry owners to make their businesses profitable, while meeting the market demand. Our dry classifiers come with bucket elevators for ease-of-output removal and require a small quantity of air for purging. The classifier is fitted with hoppers with a rotary air lock for facilitating fines removal without stopping,” explained R.S. Raghavan, managing director of Proman Infrastructure Services.

Raghavan said Proman is looking into producing its tracked plants at its new manufacturing facility in Bangalore. “We are also now venturing into industrial and metal waste recycling. We have entered a joint venture with Wendt for recycling of metal waste as there is a high demand for recycled steel in India. This is owing to the high cost of finished steel from primary ore.”

Indian crushing and screening manufacturer major Propel Industries launched its new 350 tons per hour cone crusher, the AVC 350. Senthil Kumar, Propel Industries managing director, said: “The cone crusher offers multiple benefits like lower installation costs, heavy-duty design and rugged parts to keep operating costs down.”

Propel also unveiled its new track-mounted QM 2505 Endurer cone crusher. “The crusher has been designed to operate between capacities of 150-380 tons per hour,” explained Kumar. “The product has also been designed to maximise throughput and product shape in a wide range of crushing applications. The inclusion of a double-deck vibrating screen allows the oversized material to be circulated for re-crushing and for sized end products.”

The track-mounted PSS 1550 two-deck scalper was another new plant showcased by Propel. The model’s top-deck size is 4800 x 1540mm and the bottom deck is 4700 x 1540mm. “The PS 1550 scalper is a combination of extremely accurate scalp material screening of end product and high output,” noted Kumar.

Action Construction Equipment (ACE) displayed its 49, 74 and 95hp backhoe loaders. Manish Handa, ACE vice president & business head, Earthmoving & Road Construction Equipment Division, said: “We will promote our 95hp, 4x4 drive backhoe loaders for use in India’s hilly terrain areas, especially for the Northeastern India market. While some backhoe loader manufacturers have gone slow in the 49hp-class, we have continued to produce the machine. Our new 95hp-class backhoe loader, which has undergone rigorous trials for two years, will deliver lowest cost of operations and high productivity through its front- and back-end loading.”

Indian manufacturer ACE’s 95-hp backhoe loader is equipped with an Indian Mahindra engine, Carraro axles and Parker hydraulics. ACE exports its backhoe loaders and other equipment to Africa, Middle East and South Africa and a number of former Soviet Union countries.

Hyundai India displayed its 2021-launched HX360 and HX 380 excavators. Raja Sharma, the company’s head of marketing, said: “We have positioned our 36-ton HX 360 for the quarrying industry to work with high-capacity crushing and screening plant, which are increasingly being used in extremely time-sensitive and bigger road construction projects. The 38-ton ton HX 380 is good for marble and granite quarrying applications.”

Sharma said that as well as the new excavator duo, manufactured at Hyundai India’s Pune facility, the company is looking to strengthen its offer position in the 20-ton excavator class, where Hyundai India already enjoys a healthy market share.

Coimbatore, Southern India-based Hailstone Innovations unveiled a series of crushing and screening solutions, including its Smart JHF 200 wheel-mounted, 200 tons per hour crusher with combination of grizzly, jaw cone and four-deck 1850mm x 6000mm screen. The plant, equipped with Hailstone’s JC 100 jaw and HF 220 cone crushers, is well suited to crushing hard rock types such as granite and basalt. The company also showcased its Smart Impact Series vertical shaft impactor, the VSI EP7X187. The wheel-mounted, dual-power plant is also suited to crushing hard rock types. Hailstone Innovations also displayed its new, 650 tons per hour HTS 1860 4D four-deck 6000x1800mm screen.

R J Williams, managing director at Hailstone Innovations, said: “In order to hedge the rising initial procurement costs of the equipment, we have been looking to provide cost-competitive solutions to our customers, so that they can lower their operating expenses. These are characterised in our machines, which deliver the rated output with a compact footprint. Our JHF 200 is one of such products to be launched in India for the first time mounted on wheeled chassis, having a combination of jaw-cone and screen. The wheel-mounted chassis makes it easier for transportation between sites with a prime mover.” Telematics is a standard feature in Hailstone’s plants, Williams noted, adding: “This gives information on the set-up times, loading and unloading times of the feed and crushed materials, diesel consumption etc. also ensures higher availability of our plants.”

Indian blast-hole rig manufacturer PRD exhibited its new machines for domestic and overseas customers. Mithunraj Paranthaman, CEO PRD Group, said: “Our new blast-hole rig is targeted at the granite quarrying industry. The product comes with a new drifter arrangement. Featuring high levels of compactness, the blast-hole rig comes with an onboard compressor and new hydraulic circuit. The product can be used in the aggregates quarrying industry as well as in the granite industry.” Paranthaman added that PRD’s blast-hole rigs feature advanced technology that helps deliver “cost-effective, high-performance and safe drilling solutions,” that can be custom-built to suit site conditions.

Aiming to lower equipment downtime and lessen maintenance cost, polymer technology specialist Trelleborg India displayed its Roto L and SG seals. “One of the key benefits of Roto SG is that it will help to reduce downtime of rigid dump trucks, especially those involved in removal of overburden, transportation of crushed mineral ores and allied materials,” said Ranjan Sen, the company’s managing director.

Trelleborg India’s Roto L and Roto SG are fitted on the axles of rigid dump trucks and a sensor-based system continuously checks the tyre pressure of loaded or empty trucks while in motion. “The real-time monitoring of the tyre pressure not only reduces the fuel consumption but also repressurises the tyres as and when needed for safety during operations. Roto L is the first-ever active seal to extend the seal life of the axle systems. It only seals when the seal is required, reducing friction to lower fuel consumption,” said Sen.

Trelleborg India also displayed the Nexus Metal face seal for excavators and other equipment working on fast duty cycles. The seal features a heavy chrome casting, preventing the contamination of the hydraulic system. The seals can be used in hydraulic systems, gearboxes, transmission systems and power take-off systems in machines like concrete transit mixers.