Metso Outotec’s high-resilience Trellex 300TS rubber screening media is helping Votorantim Cimentos to nearly eliminate contamination and fines and increase operational efficiency (OEE) by 11% at the group’s Santa Isabel quarry in Brazil.

Located in Mogi das Cruzes, in Greater São Paulo, the Santa Isabel site has been in operation since 1959 and serves customers in the metropolitan region of Brazil’s largest city. The quarry provides aggregates for civil construction, major works, and cement block producers.

Despite the quarry’s current success, it was a different story in 2018. At that time, Santa Isabel faced two major challenges. In addition to reduced civil construction works, the plant was having problems due to aggregate contamination and an above-average presence of fines. Both hurt buyers’ perception of the final quality and Santa Isabel’s sales. In the sand and gravel market buyers prefer materials with controlled levels of contaminants and dust. In other words, ‘cleaner’ aggregates.

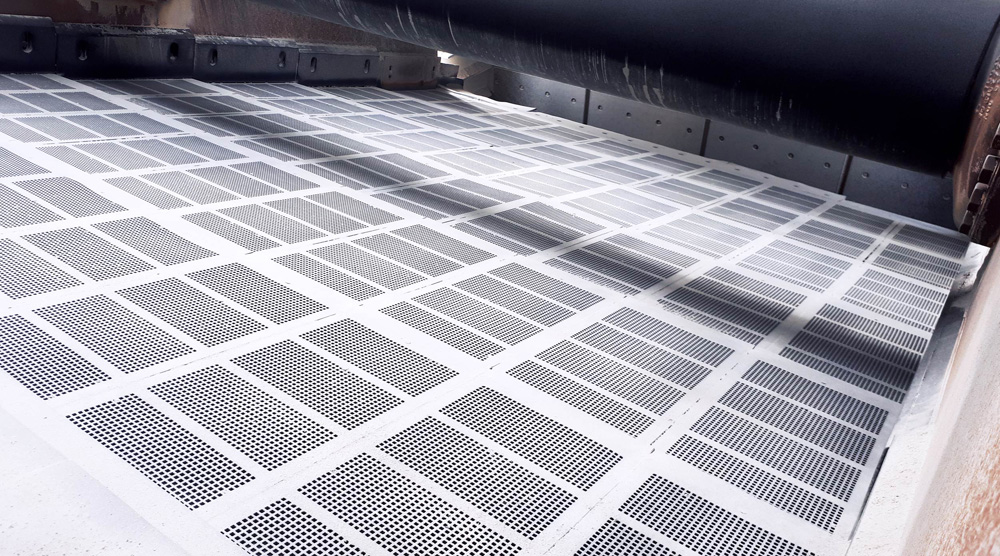

With the arrival of the new regional manager, Carlos José Barbosa Silva, Santa Isabel began to implement operational changes, including training employees and addressing the main technical problem: the aggregate screening process’s improvements. Specialists from Metso Outotec were invited to assess the operational efficiency of the screens. “We had already faced a similar problem at our Araçariguama site and achieved good results with the solution presented. The screens were retrofitted and the wire media replaced with Metso Outotec’s Trellex 300TS screening media with high-resilience self-cleaning panels,” explains Carlos Barbosa, Votorantim’s regional manager.

At Santa Isabel, Metso Outotec replicated the tests conducted at Araçariguama.”In Araçariguama, the tests involved the simultaneous operation of two screens: one with wire media and one with rubber media. When the media change-out was made, an analysis was performed in the site laboratory. We discovered that rubber screening media nearly eliminated the final product contamination and reduced the presence of fines. Even with a smaller open area, the high-resilience Trellex 300TS rubber media is much more efficient than the wire media,” says Metso Outotec’s screening specialist André Rosa. The tests played a decisive role in selecting Metso Outotec as a partner for Araçariguama and, later, for Santa Isabel.

While the screens alone were not the reason for the improved operational performance, the screen adjustments and the use of Trellex 300TS rubber media were key factors in the increased production quality. An analysis of the end-user feedback supports this: the quarry index of one complaint about every 37,000 tonnes produced (2018) changed to one complaint about every 700,000 tonnes produced, an improvement of 20 times and ten times better than planned. The current assessment parameter is ten times higher than the specified target of one complaint per 67,000 tonnes. “It was a fantastic leap that surprised everyone. We didn’t miscalculate our goal. The results of the changes were significant,” adds Barbosa.

The challenge of the above-average presence of fines was addressed by optimising the screening solution. Furthermore, the main action to address the internal contamination, i.e. the unwanted mixture of different products, was training. Internal contamination was reduced by correcting the loader operators’ improper procedures when moving products in both operating shifts. Mistakes made by third-party drivers transporting products from the quarry to customers were also identified and corrected through appropriate guidance. However, the best indicator of success is pricing. In July 2019, for example, the price of stone powder had been increased seven times in a row. The recovery of the price negotiated between local customers and increased production was complemented by bold screening changes that created an intermediary product between fine and medium gravel. This has improved the quality of concrete block production with lower cement consumption and higher mechanical strength and visual quality.

“There is pent-up demand already being seen, but our production should be able to keep up by making screening adjustments,” says Barbosa. He notes that Santa Isabel has a lean operating approach, increasing productivity by 4,000 tonnes per employee since 2018.

“Some of the buyers of our sand and fine gravel are concrete block producers who have automated machines and demand a high homogeneity standard. They were the first to observe the change in the quality and appearance of our final product,” summarises Barbosa.

Speaking to Aggregates Business, CDE’s Thomas Patterson, senior technical engineer, and Mark Ballantine, senior product development engineer, highlighted that the Cookstown, County Tyrone, Northern Ireland-headquartered washing plant manufacturer had in recent years seen a big increase in demand for plant set-ups focused on C&D (construction & demolition) waste recycling applications.

“We had a more simplistic approach to the recycling market four to five years ago as the needs of the market were very different,” explains Patterson. “Then, our customer was just looking to divert products from landfill, make them saleable, get them out of the door and get a quick return on investment on it.

“Now, it’s gone from one sand and one aggregate to two in-spec sands and four aggregates, which are CE certified. That is a drastic change in the range and quality of the final product, which is supported by the level of investment that a customer wishes to make in the complexity and capability of their recycling plant.”

The screening element of the plant set-up for recycling and other customers in the quarrying, mining and construction industries includes screen media based on a longstanding partnership between CDE and screen media specialist, TEMA Isenmann, the UK-based subsidiary of German company Isenmann Siebe, one of the world’s leading manufacturers of screen media and ancillary products.

“We have a very close relationship with TEMA Isenmann,” says Ballantine. “If there are any problems that arise in the field or anything in our screen media that we think we can improve, be it cut-point efficiency, throughput capacity, or dewatering capacity, we know we can find the right mat for the optimised solution. It’s a continuous feedback loop involving our sales and technical engineer teams and the customer.

“With recycling projects, you may at one stage have loads of fine materials that need to be screened and dewatered, which will affect your dewatering capacity or fines management. Then next week, you want to get rid of larger sized particles.”

CDE has a range of 15 Infinity-branded screens for dewatering and product-sizing classification. “There’s a lot of novel features across that range, like Trilogy side walls and bolted construction, and we’re working on two more screens to add to it,” explains Ballantine. “There is modularity in the Infinity screens design and adaptability, allowing them to accommodate different screen media. The wide breadth of our screens means you need a wide arsenal of screen media to go with them, which we can get through our partnership with TEMA Isenmann.”

Patterson notes that CDE uses its Infinity range of screens on its plants for customers across both material handling divisions, natural processing and waste recycling. “CDE incorporates three main principles of good screening media, that is, plant performance, maximising tonnes per hour; durability, so you have good plant protection and minimum downtime; and ability to achieve tight product specifications.

“In each material processing solution from CDE, the screening media is tailored to every application. For example working with a crushed manufactured sand is different to working with an alluvial natural occurring sand where the shape and texture of the two particles appear different, and aperture size and shape are very important to retain maximum screen efficiency.

“With a crushed rock application, given crushed rock is very sharp and angular, a slotted mat may be more suitable to gain more screening efficiency. Whereas a naturally occurring product [glass sand] that is rounder and alluvial is going to be more easily screened with a square aperture. Top-cut-point protection and low-cut-point protection is also much more easily achieved.”

Patterson says around 55% of CDE plant orders in 2020 were repeat customers. “I think the growing relationship we have with these repeat customers helps make each project a success, and that includes the screen media that we supply to them.”

Ballantine highlights how CDE has invested heavily in improving its testing capabilities, especially when dealing with specialist sand applications. “For those kinds of customers, we get a large volume of samples and test them on our screens in our dedicated test rig. You have all the theory and the calculations but being able to thoroughly test out a tailored plant set-up gives us peace of mind that the set-up will be fit for the task in the field. We want to be clear with our performance commitments to every project, and we want to be accountable for the solutions we provide, so it’s important that we get technical certainty around what we’re supplying.”

As well as being the year when CDE opened its new eye-catching, state-of-the-art global HQ in Cookstown, 2019 also saw the company move into its first in-house manufacturing facility in Monkstown, County Antrim. “Prior to that, all our manufacturing was sub-contracted out. Moving forward, we envisage a shared approach between in-house and partner suppliers,” says Ballantine. “That brings greater flexibility in how we work while also speeding up product development and ensuring better quality control. It’s been a very positive development.”

Patterson adds: “The big thing for me is the collaboration that the new HQ and manufacturing facility has given us. The new HQ building also gives us a great opportunity to invite our customers in and complete a technical design workshop where we can transform our customer’s vision or idea into a world-class solution that can be visualised on the same day.”

MAJOR says it has seen encouraging demand for three products launched at the CONEXPO/CON-AGG exhibition in Las Vegas, USA, in March 2020. The product trio is said to maximise the productivity and efficiency of MAJOR’s popular FLEX-MAT range.

The FLEX-MAT ID-Enabled system has been designed to track and store screen-media data such as panel dimensions and customer-defined details to offer users information at their fingertips for simple reorders.

The FLEX-MAT Sensor is a valuable and easy-to-operate vibration data-measurement tool to review results and fine-tune screen machines without shutting down the equipment.

Meanwhile, MAJOR’s smartphone app gives customers up-to-date information and access to advanced digital tools. The MAJOR App is available for aggregates and mining producers, and MAJOR dealers, with customisations for each. It integrates with the latest MAJOR technologies, including the company’s FLEX-MAT ID-Enabled and the FLEX-MAT Sensor.

Lars Bräunling, MAJOR director of product technology, said: “2020 wasn’t the launch year we — or anyone — was expecting, but even so, the FLEX-MAT Sensor, MAJOR App and FLEX-MAT ID-Enabled have all been well received with varying levels of feedback and utilisation.

“Our dealers say the FLEX-MAT Sensor — our screen box vibration data measurement tool — is an absolute game-changer. Almost every MAJOR dealer now owns the tool, which has made it easier to complete professional assessments and check-ups of customer equipment since it doesn’t require the screen box to shut down to be measured. It’s been eye-opening for quite a few of our customers, especially a couple of operations for whom dealers using the Sensor were able to prevent bearing failures by noticing discrepancies in vibration data and prompting further investigation. The regular use of the Sensor has allowed for tracking of machine development as well as more informed preventative maintenance. Moving forward, we’re continually looking at ways we can expand the information the Sensor collects as well as figure out new and innovative ways to use it as actionable data.

“The MAJOR App is rolled out and is being used by our dealers and customers not only to use the FLEX-MAT Sensor and ID-Enabled but as a resource for newsletters, product details and other MAJOR information. We are continuing to develop the app and its features.

“Our FLEX-MAT ID-Enabled Radio Frequency Identification (RFID) technology will be included on all new FLEX-MAT screens this year. The microchip tracks and stores screen media data such as panel dimensions and customer-defined details to offer users information at their fingertips. It’s a comfort feature available if our customers want to use it, and we expect more and more will realise the benefits of simplified screen media ordering and inventory management.”