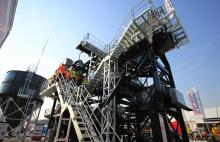

Organised and hosted in conjunction with one of TWS’s French distributors, Catecom and its customer, Santrac (celebrating 40 years in business), the event attracted more than 80 guests including TWS dealers, their customers and Santrac’s customers, who had the opportunity to see the Terex Aggwash 60-1 wash plant in operation.

The plant, on the Santrac site, is processing natural sand and gravel following the company’s search for a solution to process the materials that were particularly clay-bound, with a high level of silt.

“The Terex Aggwash mobile wash plant brings together rinsing, screening, scrubbing and sand washing capabilities on a transportable single chassis. Primarily designed for the processing of construction and demolition waste, it is equally suited to virgin material applications. The Aggwash is capable of producing four grades of aggregate and one or two grades of sand with a capacity in excess of 70tonnes per hour,” says TWS.

With a pre-wired and pre-plumbed design, the logwasher component of the plant breaks up the clay-bound material, liberating the clay and sand from the stone producing three aggregates (4-8mm, 8-20mm and 20-40mm), one oversize (40mm+) and one concrete sand.

“We were delighted to welcome so many customers and dealers to the open day, which proved to be a great success with sales following after the event,” says Fergal McPhillips, TWS sales manager.

“Catecom has grown over the last two years, clearly demonstrating an acute understanding of the washing demands in France. They have greatly increased market share and have expanded their business line for greater future growth within all washing segments such as concrete and building sands and in wash recycling.”

Patrick Palais, Santrac quarry owner, says: “The Aggwash wash plant has been operating very effectively for us since the installation. We are much better placed to serve our customers’ needs.”