The patented Ty-Rail system is said to solve an age-old problem of time intensive screen media change-outs. Replacing tension rails is typically time consuming and requires removing and replacing many pieces of hardware per screen section. Washers or bolts are often dropped or lost in the process, which adds to downtime and parts costs. The Ty-Rail system is said by Haver & Boecker to provide a fast return on investment, and cuts screen change-out time in half.

Haver & Boecker will launch Ty-Rail 26-28 September at booth 12050 in Silver Lot, during MINExpo in Las Vegas, U.S.

“We continue to lead the aggregates and mining industries in innovation that’s focused on improving efficiency. Our engineers’ invention of the Ty-Rail system solves the long-time problem of lost parts and difficult, time-consuming screen panel change-outs,” said Karen Thompson, Haver & Boecker Canada president. “Our customers will undoubtedly experience increased uptime and, as a result, increased profits by using this revolutionary tension rail system.”

The system was developed and designed by a team of engineers led by Haver & Boecker vice president of engineering and technology, Dieter Takev.

“We’re continually looking for ways to minimise the challenges mines and quarries face,” Takev said. “Our team spent countless hours brainstorming and discussing some of the biggest issues we saw during our many site visits and heard about in discussions with customers. After nearly two years of design, development and testing, Ty-Rail is ready to serve and improve our customers’ operations.”

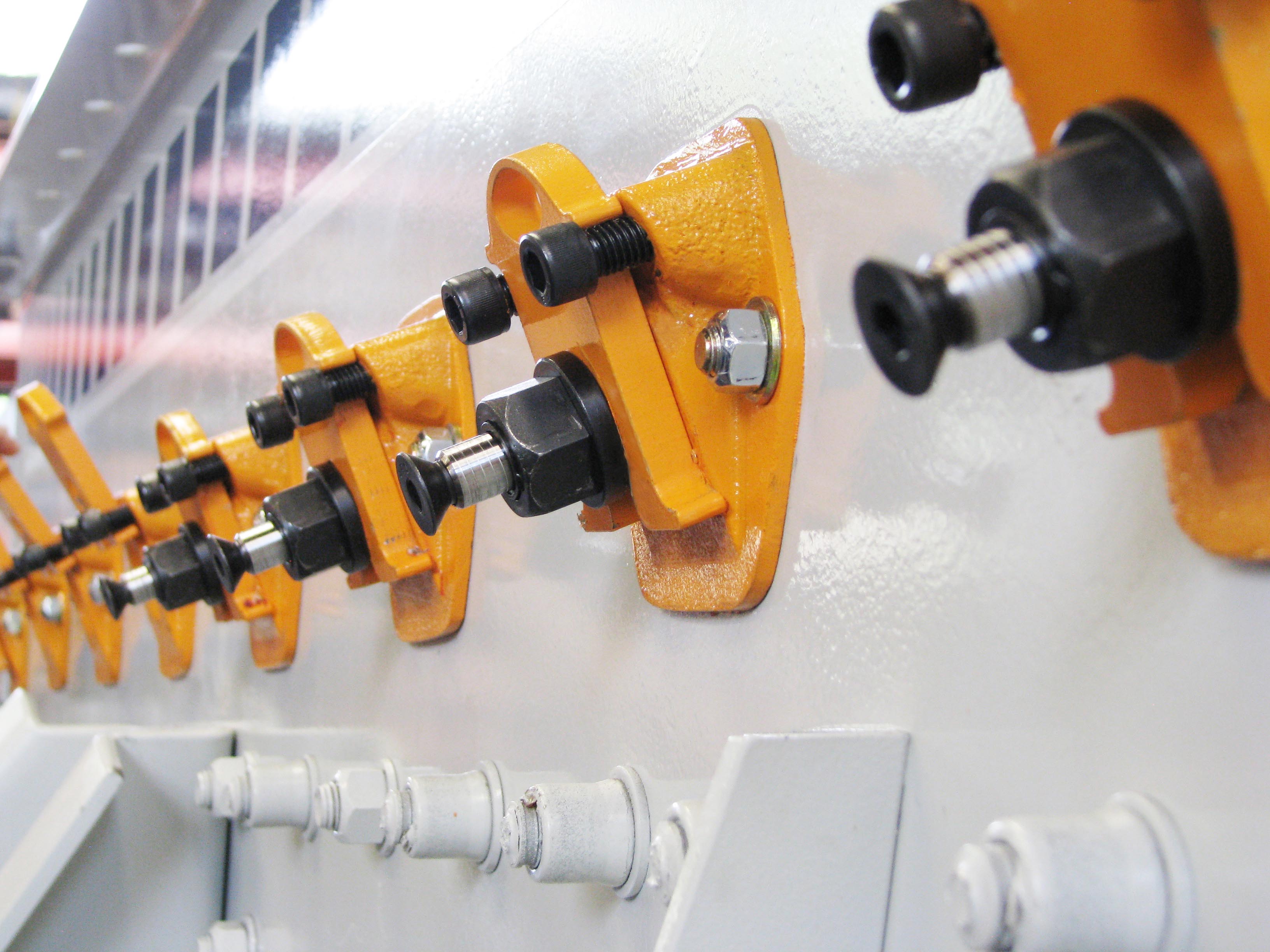

Each Ty-Rail package includes two tension rails, eight angle boxes and eight bolts; all the hardware required to change one screen section. Once installed, each rail becomes a singular, removable piece since the bolts remain attached to the rail, and the angle boxes remain attached to the vibrating screen. To remove the tension rails, an operator simply loosens the bolts on each, shifts the angle boxes up, and lifts the rail and bolts out as one piece. This reduces screen media change-out times by about 50 percent. Additionally, the innovation can take the task of changing tensioned screen media panels from two people down to one.

“For decades, our Tyler brand has been leading the way in innovative processing technology and quality,” Thompson said. “Productivity plays a significant role in production, which is why we developed the Ty-Rail system: to provide our partners in the mining and aggregate industries with a method to simplify tension rail change-outs. Now, producers can drastically reduce downtime and, therefore, increase their production and profits and achieve better ROI.”

The system is designed specifically for Haver & Boecker’s Tyler brand of vibrating screens and is now standard on all new F-Class and T-Class machines. Producers can also refurbish older Tyler vibrating screens and add the Ty-Rail system.