After more than three years of development,

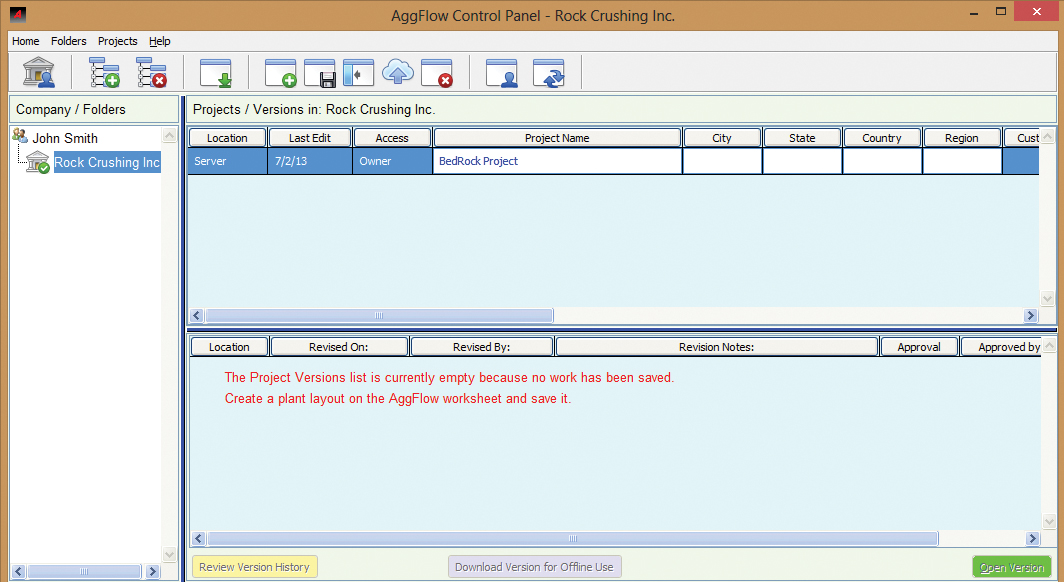

AggFlow Design and Manage (AggFlowDM, now available, represents a new generation of simulation software to manage and optimise a quarry, mine or aggregate plant operation.

AggFlowDM is a hybrid program that allows users to work online or offline and to share projects with other users. The sharing capabilities allow aggregate process engineers, consultants and equipment dealers to work most effectively and efficiently when developing plant optimisation strategy.

AggFlow users can use the simulation to accurately determine optimal production capacity for a particular equipment configuration and then input field sample data into the simulation to compare what the operation is actually producing to its theoretical capability. By identifying areas where actual production varies significantly from theoretical capacities, process engineers can identify and eliminate bottlenecks and inefficiencies in the operation.

AggFlow is also used to design new equipment applications to ensure the proposed equipment will meet installation requirements. AggFlowDM takes this functionality one step further by providing users with the ability to share simulations online and to store plant and equipment data in a private database.

“The flexibility AggFlowDM provides will have an exponential impact on our customers’ ability to develop and share project simulations. Both the sharing and database storage capabilities will greatly enhance their ability to optimise and maximiae plant production.” says Robert Teller, managing partner of BedRock.

All new program users will be provided with AggFlowDM, and all current AggFlow users can upgrade to AggFlowDM free of charge.