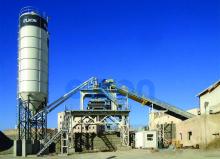

Turkish concrete-batching plant maker

The customer is said to have placed the order after being impressed with the ELKON-60 Quick Master plant exhibited at the

The newly commissioned concrete-batching plant is equipped with a 2m³ twin-shaft mixer, a skip hoist system and four aggregate storage bins, each with a 20m³ capacity, allowing for the use of a one-sided ramp. Three 75-tonne cement silos were also installed on the customer’s work site.

Stringent requirements imposed by France on the quality of concrete and concrete-making equipment resulted in the integration on the ELKOMIX 120 Quick Master of sand moisture sensors, an automatic high-pressure mixer cleaning system, mixer protection systems and accurate water and additive feeding systems. To protect the mixer against weather conditions and to limit the impact on the environment, the mixer block and weighing batchers were covered with a galvanised metal and polycarbonate sheets, while a filter was also installed on the mixer block. Additionally, maximum galvanisation was applied to parts and components including aggregates storage bin panels, discharging gates, cement, water and additive weighing batchers, skip bucket, all maintenance platforms and tracks, stairs, railings, and sidings.

The resulting ELKOMIX-120 Quick Master plant can produce up to 720m³ of high-quality concrete a day. An Elkon technical assistance team is on hand to support the plant’s smooth operation.