With its highly innovative and expanding product portfolio for the quarrying and aggregates sector, Trimble Loadrite is geared up for strong growth in 2015. Aggregates Business Editor Guy Woodford spoke to the company’s General Manager, Johan Smet.

With its event-record 4,200 attendees from 83 countries, numerous product launches, and 584 educational sessions including both on- and off-site immersive training,

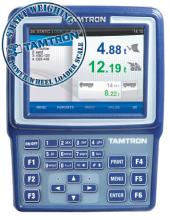

Now part of a Group which recorded a US$2.3 billion turnover in 2013 – up 12% on 2012 – that offers a vast range of advanced positioning solutions for the heavy civil construction, geospatial, agriculture, buildings, and transport & logistics sectors, the impressive Trimble Loadrite range of products includes scales for measuring payloads on wheeled loaders, excavators, conveyor belts and garbage trucks. The firm also provides cutting-edge reporting solutions for aggregates, waste, scrap metal recycling, public works, and many other industries.

“Our reach has been boosted both in terms of access to technology and in terms of access to distribution partners in new regions. This has allowed us to grow the business more rapidly than it was able to do on its own. This allows our customers to take advantage of local support around the world,” explains Smet.

“Long before the acquisition, the industry recognised the value of the Loadrite product range. That is reflected in our global market leading position. With the acquisition, we can expand the dialogue with our customers, and look beyond process steps where accurate weighing is critical. For example we can now look at blasting optimisation, and fleet and plant maintenance. The market is very interested in these applications, and that was reflected at Trimble Dimensions.”

Smet believes the quarrying and aggregates sector has a “tremendous opportunity” to achieve improved operational efficiency by using automated product packages.

“The need for our customers to extract those potential savings is increased by the ongoing weakness of markets in Australia and Europe, but also exists in less challenging environments like North America. The breadth of our offering allows quarry managers and operations teams to have a comprehensive view of what happens on their sites, from the pit, to the processing plant and the load-out area. With the right tools, customers can optimise efficiency at each step, and also look for inefficiencies across the process, which can be addressed. In addition, they can start measuring and optimising support processes, such as fleet maintenance and inspections.

“The wheeled loader [scales] product has traditionally been the highest revenue product in our portfolio. The reason for that is that the value proposition is so obvious, and the benefits so easy to capture, that almost nobody operates a quarry without onboard scales in the load out area.”

Among the new products unveiled by Trimble at Dimensions 2014 - its 7th international users’ conference - was Trimble Loadrite’s InsightHQ management solution. The web-based management portal brings together information from any Loadrite product, and allows customers to have a comprehensive look at their operations, from pit to load out.

Smet believes InsightHQ will be a key growth driver for Trimble Loadrite. “The reason I believe this is key is that it allows our customers to take the next step in analysing and managing their business and because it’s a web-based portal this can be done from anywhere and on any web enabled device or computer. As I mentioned, pretty much all quarry operations have at least a basic wheeled loader scale in their load out area. To some degree, that levels the playing field again: what was once a competitive benefit, no longer is. So quarry managers must look for the next competitive advantage. We believe that process optimisation based on real time production information is a cornerstone for that next step.”

There are many examples, says Smet, of how Trimble Loadrite products have benefited quarry-based customers. “We have one large quarrying customer who uses our reporting system to capture conveyor belt downtime information across multiple sites, and has been able to reduce black belt time; that is the time the plant or sections of the plant ran empty, by double digits on certain sites based on information from that system. That translates into very real money very quickly.

“Another example is a customer who significantly reduced the number of truck cycles and cycle times in the pit haul process, by using a Loadrite system on the excavator to significantly improve the accuracy of truck loading. They increased the average load per truck by double digit percentage (they were mostly underloading trucks out of fear of accidentally overloading them), while actually reducing the percentage of overloaded trucks. The end result was they were able to achieve weekly production targets with one less shift per week.”

Of key current regional markets for Trimble Loadrite, Smet says: “Since the acquisition by Trimble, Loadrite has gained access to virtually all markets in the world. Of course some areas are not economically attractive at this point, or have set up barriers to make them not worthwhile pursuing. Yet we have expanded our distribution and now cover the USA and Canada, most of South America, all of Western Europe, Southern Africa, and of course Australia and New Zealand. We are also strengthening our distribution and support capabilities in China and India, as well as in Mexico and the fast growing economies of South East Asia.”

Smet says that Trimble Loadrite’s business strategy does not fundamentally differ from one region to another, with the firm offering a complete portfolio of technology solutions to help quarry operators improve the efficiency of their processes.

Trimble Loadrite’s General Manager has talked previously about looking to expand Trimble Loadrite’s presence in Europe and North America, but which offers the biggest growth potential for the company?

“I’d be hard pressed to make a choice between those two. They are just different. Our relative market position has traditionally been much stronger in North America, although we’ve improved that significantly in Europe in the last couple of years,” says Smet. “North America is now also the more healthy economy of the two. On the other hand, we’re making significant investments in the European market,

both in terms of distribution capabilities and our own technical staff on the ground. So even as the economic environment is weak, we believe there is opportunity for wider adoption of the Trimble Loadrite product.”

So how does Smet see the quarry of the future? All automated using Trimble Loadrite products?

“I am always wary of pulling out the crystal ball in public, but we believe the quarry of the future will be more transparent and as a result more efficient, that’s for sure. The famous ‘internet of things’ will also affect this industry. The experience may be a bit rocky as people get used to new ways of managing their operations, but ultimately it will be greatly beneficial.

“Automation is a separate topic. I remain convinced that people will have a very important role to play for a long time to come. Quarrying is an outdoor activity, subject to many unpredictable factors. That is a lot harder to automate than an indoor factory, where the environment can be perfectly controlled. As a result, human judgment will continue to be very important. Automation of course has a role to play, but I think it will go through several stages, starting with better information in the cab, operator assistance in the cab, and then slowly evolving to remote control, etc., each one with its own adoption curve and time. New technologies require businesses to change the way they do things every day, and that takes time.”

Smet says there are many achievements he’s proud of during his ten-and-a-half year career to date with Trimble, and, since mid-2013, Trimble Loadrite.

“I am mostly proud of how the Trimble Loadrite team and the Loadrite distributors around the world have handled the transition. Acquisitions can go wrong in several ways, but we have successfully aligned key functions and technologies with the wider Trimble organisation, allowing us to continue to grow the business with relatively less incremental fixed costs, and we have done so without losing any key staff or any distributors, and in fact growing the business faster than in previous years.”

What advice would Smet give to young professionals looking to build a successful career in his sector of the quarrying and aggregates industry?

“I believe of course that the application of advanced technologies to any industry is a fascinating area to build a career. The bottom line benefits of applying cutting-edge technology to improve operational performance in a traditional industry are bigger than almost any other initiative. These are fascinating times, as current managers succeeded the generation that ran things purely based on hundreds of years of experience, and who are being challenged by an incoming generation who grew up with nothing but technology. In every operation, there is going to be a need for a ‘technology champion’: the person who can make the boss look great, by providing the right advice for technology investment, keeping it all running, and making sure management draws the right conclusions. It is not a formal role, and someone with the right ambition can position themselves into that role and be very successful.”

With Trimble Loadrite going from strength to strength and despite travelling across the globe promoting the firm’s product portfolio, Smet still manages to find some time to relax and unwind. “I have three kids and we moved the family to New Zealand at the beginning of the year, so when I’m not traveling for work, we invest our free time mostly in exploring Auckland and New Zealand. It’s been a great experience for the whole family, so it’s going well both professionally and personally.”