Various weighing systems, static and mobile, are available to quarry and recycling operators as Patrick Smith reports

Accurate weighing and measurement is vital for improving quarry productivity. For example, prior to billing a customer it is essential to know the weight of each load, and a variety of specialist systems are available to calculate this and to make sure trucks leaving a quarry are not too heavy for the roads they will travel on.

Static or dynamic weighing systems are often used to measure the quality and quantity of products sent to customers and there has been much development in integrated belt scales, volumetric hatches, weighing conveyors and on-board systems and associated management and control software programs, by a number of manufacturers including

However, quality measurement has not always been readily available for mobile conveyors, claims Soeren Schramm, product manager for

“Traditionally, belt scales have only been used on fixed, not portable plant equipment, because the shorter length of conveyor belts on portable plants has not been sufficient for accurate results. But being able to accurately weigh materials crossing the conveyors on a mobile crusher, screen or stacker is really important if operators want to get the best results from their business,” says Soeren.

His company’s C-Weigh belt scale has been developed specifically for the portable equipment environment, with rugged components, flexible frames, modular installation and a repeatable accuracy, and has been installed worldwide in mines and quarries.

It is claimed that with a C-Weigh belt scale on mobile equipment, operators can access reliable data on tonnage crushed per hour, day, week or month, and an overview of the efficiency of the crushing and screening processes.

“The scale frame is very well suited for retrofitting and doesn’t require major structural modifications, and it is tolerant to shock, vibration and extreme temperatures. The design ensures C-Weigh is very cost effective and unobtrusive so retrofitting is very achievable,” says Soeren.

A range of reporting options is available to suit the needs and experience of the user.

“It starts with the simple digital display that shows tonnes per hours and total tonnes. It is also possible to print out the report using a hardy printer specially designed for the system, or reports can be emailed directly to the user’s inbox. Connection to Loadrite’s MMS [Multimedia Message Service] allows for basic inventory and stockpile reports or the system can be integrated with third party software.”

For advanced reporting requirements, the C-Weigh can be coupled with Loadrite’s Insight software, a new web-based system that offers the reporting power of expensive PLC/SCADA systems “at a fraction of the cost.”

C-Weigh uses the same robust user interface as Loadrite’s wheel loader scales, and works with a range of wireless data communications options including Wi-Fi, radio modems or cellular modems and is able to fit most crushers, screens and stackers.

Last year, Bell Equipment UK worked closely with Loadrite to develop an advanced payload system (APS) for its entire wheeled loader range. Designed to be ‘plug and play’ the payload system enables target load input, multiple material measurements, multiple attachment calibration, batch loading data where the operator mixes materials, and recall and subtract of last bucket load, which can help counteract one-off errors.

The company’s articulated dump trucks also offer an on-board weighing system.

The Finnish

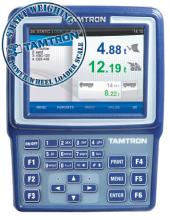

The product range, the Power 100 (basic scale); Power 200 (advanced scale) and Power 300i (online scale), has digital technology to increase loads and productivity with loading speeds of up to 500tonnes/hour. The Power 100 model can be upgraded to advanced models 200-300i.

A sunlight readable touch display and hot keys offer user-friendliness while the system is fully dynamic with weighing during bucket lifts as the loader is operating normally. The scale compensates automatically for errors caused by lifting speed, machine tilt and acceleration.

“Improved loading speed, accuracy and productivity differ from the traditional analogue loader scales,” says Tamtron.

“There is also automatic angle compensation for increased accuracy and faster loading.

“The latest carriage to storage mode is a standard feature on the scale, which serves both the need to weigh basic loads as well as for use with advanced memo items.”

The Tamtron POWER 100-300 range has the colour touch display with a logical user interface, and the scale serves both basic and professional weighing needs. For example, with the basic weighing mode any user can weigh loads and with the memo weighing mode professional operators produce necessary weighing data for further processes.

“Carriage to storage mode is an improved and easy-to-use feature. Crushed materials and other truck loads to storage are monitored accurately and with ease,” says Tamtron.

With online data transfer, weighing data flows in real-time from the scale to invoicing and orders are sent wirelessly from the platform to the wheel loader and so the work orders are executable immediately on the scale display, thus improving loading and storage control.

The Power 100 has two main memos and optimal loads are reached with the weighing of last bucket and subtracting the overload. Carriage to storage mode is optimised to weigh materials transported to storage and to manage stocks.

The Power 200 advanced scale has eight main memos for data such as customer, truck, trailer, material, loading site, order number, and driver. Some 10,000 plain text data can be stored in the databases.

“The scale has integrated functions for comprehensive shift/day/week/month reporting and a log memory.

Features such as control of emptying bucket, count of loaded buckets, and automatic retrieval of previous loading data demonstrate the versatility of the advanced wheel loader scale,” says Tamtron.

It Power 300i has same standard features as the Power 200 but with added online data transfer services and 12 main memos. Besides weighing results, the scale records automatically stock levels and usage and location of the loader.

Following the purchase of a range from Nordic Bulk

“These include onboard belt weighers with an accuracy of between ± 0.5-1.0% which offer a flexible solution to suit all types of crushers either mobile or static within the quarrying, recycling and demolition industries,” says Les White, Precia-Molen’s sales and marketing manager. The company recently supplied a Precia-Molen FXM Belt Weigher, the first FXM to be fitted in the UK by the company, to Tyne Tees Crushing & Screening (TTCS) in north-east England. The company, part of Tyne Tees Demolition Group (TTDG), operate a fleet of mobile crushing and screening machines producing quality recycled aggregates from its own demolition contracts, as well as forming part of the company’s contract crushing and screening fleet.

TTCS bought an adapted Precia-Molen FXM Belt Weigher, which was then fitted to an

Accurate weighing is an essential priority for TTCS in the production process, and if the machine is moved this means the onboard conveyor is folded when the machine is re-sited. When the conveyor is opened out for operation again the FXM automatically recalibrates offering immediate weighing.

The FXM is a weighing frame with a single idler station utilised in integrating belt scales designed for production weighing applications and comprises two adjustable height weighing units with integral load cells and a single idler station with special rollers for extremely low build-in height.

“Ideal for mobile crushing and screening machines this new technology has enabled the design of a compact assembly with separate adjusting systems for height and trough angle to accommodate the belt conveyor,” says Precia-Molen.

The assembly is suitable for 400-1,800mm wide belt conveyors with a conveyor speed up to 2m/second and offers a maximum throughput of 2,000tonnes/hour for all commodity types.

“The Precia-Molen FXM scale has the ability to view the current speed of the belt, which is an essential vital element when there is only a fixed period window to discharge, as the belt speed can be increased to suit the flow of products.”

After installation, the FXM scale was connected to an onboard I400 Programmable Indicator which is said to provide a solution to the integration of weight measurement in any industrial process.

Next generation

“In addition, the Loadmaster iX range offers effective management of weighing data. The Loadmaster 8000iX has an integral SD card port for the fast and efficient transfer of data between loader and weighbridge or office PC and enables pre-registered customer reference data to be uploaded directly to the instrument,” says RDS Technology, which also offers the Loadmaster 9000i. When fitted to a wheeled loading shovel, the onboard weighing scale effectively transforms the loader into a mobile weighbridge.

Celebrating an increase in interest and recent orders for its Loadtronic 3 products for tipper trucks is

A recent order for 20 systems was received from Attero, one of Holland’s largest recycling companies, and another reference user is EMO in Rotterdam, the world’s largest dry bulk terminal handling more than 35 million tonnes of coal and ore every year.

“It’s really great to be able to supply our weighing systems to such a large, international player,” says Harald Jørgensen, product manager of Loadtronic products.

“We believe that the market for such systems will grow when customers see that it is a very helpful tool for the operator. Fines for overloaded trucks will become rare with our system. The possibility to track productivity is also important.”

The

“Under the previous system, which was not as accurate, we had to include a safety margin of at least 15%, which meant that we couldn’t load more than 85tonnes in each car,” says Paul Hinskens, manager of machinery at EMO.

If any of the cars are overloaded the trains are sent back to EMO, and this leads to a heavy fine by the train operator and extra work for EMO.

“Today we can use each car to the maximum level and accurately load 100tonnes. This is 15tonnes extra per car, with 52 cars per set, thus a total 780 tonnes extra. Which makes for good economics,” says Hinskins.

Loadtronic 3 and 3E weighing systems for wheel loaders and excavators measure and compensate for different forces during weighing, and give high accuracy, high-speed weighing.

“Time saving and less fuel consumption due to correct weighing every time is one of the main reasons for choosing Loadtronic 3. The system has 16 different languages available,” says Jørgensen.

Loadtronic 3 has high capacity data storage and data can be sent by wireless or via USB to the office computer, in text or Excel format, while the weighing system for excavators, Loadtronic 3E, is built on the technology of the wheel loader system, but with more angular and rotation sensors. It is a dynamic system: the load in the bucket is being weighed during a normal loading cycle. Every function such as data storage is the same as in the wheel loader system, and it can be installed in machines with normal buckets as well as with such attachments as grapples and stone rips.

Award winner

Voted a winner in the Intermat 2012 Innovation Awards was Volvo Construction Equipment’s On Board Weighing (OBW) system for its F-Series haulers which is available for Volvo CE’s full suspension haulers and is said to “give an unprecedented insight into machine productivity.”

The system monitors the input of weight on the machine from pressure sensors and relays this information to load software integrated into the machine’s electronics.

Fully automatic, OBW logs all transported loads and the ensuing data is then displayed on the operator’s display. The information can also be accessed remotely using Volvo’s advanced CareTrack telematics system. This allows complete payload management, giving access to data such as total transported load in tonnes; tonnes transported per litre of fuel and number of cycles.

“The system highlights if the machine has been overloaded during any of its cycles on a load indicator light mounted outside the machine. A yellow light comes on when at part load and this changes to a green light at nominal load, finally turning red when overloaded,” says Volvo.

“This simple tool helps prevent overloading and the machine wear, tyre damage and excess fuel consumption that go with it. The nominal load can be preset to suit material and site requirements.

“OBW, together with fuel consumption data, help show the true productivity of the machine, combing fuel efficiency with tonnes of mass moved. Additionally, it can help in improving operator performance. The OBW system also offers the ability to unlock a wealth of previously inaccessible information, such as the weight of ‘carry-back’ left in the haul body after tipping.”