The latest on-board weighing systems are providing quarry operators with more than just loading information. Claire Symes reports

At one time weighing in quarries was limited to weighbridge operations in the loadout area but now a wide variety of dynamic and static weighing systems are available. These make it possible to carry out weighing at almost any stage of the production process and integration of this into management systems is adding real value for quarry operators.

"We are seeing an increased requirement to take what's happening on the quarry floor and feed it into the management system," said

"Quarry operators want to know exactly how much material their loading shovel is moving per hour and per day. It also adds traceability with information about where the material was loaded and which bay or customer it was delivered to.

"It is a mix of customers that are demanding this - not just the bigger players - because they all want to focus on more efficient use of machinery and manpower.

Using data direct from the weighing system offers a more efficient and quicker means of collecting and analysing the load information." This trend has also been seen by Actronic EAME business manager John Vaasen. "They realise that there is a need to look at operational efficiency and make improvements," he said. "Investing in weighing equipment may not make a big contribution but it all adds up if you measure and monitor the weight all the way through production.

"It allows quarries to monitor the efficiency of the blast and work out if they could get more for their money, for example. At the moment operations have more time to review methods but unless they are under financial pressure they are not looking at it.

"Corporate operators are looking for more management information and best practice and measuring process and production forms a key part of this. It all comes down to cost per tonne."

Accuracy

"Accuracy is an issue for specifying weighing equipment - different markets expect different levels," said Precia Molen regional sales manager Jeff Buxton. "In the UK 5% is acceptable but in Europe many countries want 0.5%.

"If taking material from extraction, then 2-5% is adequate but in France for example, bonuses paid for production at the primary crushing stage are the drivers for higher accuracy. It is possible achieve very high accuracy under the right conditions but it comes at a premium. Many quarries are not investing in the right technology to get the results they want." More quarries are investing but some doubt the accuracy of all systems and are unsure of dynamic ones, according to Buxton. "The benefit of dynamic over static systems is that offer continuous information that can be effectively used to increase production," he said.

The technology for dynamic weighing is moving quickly and can now provide a high level of accuracy. The accuracy depends on the range of the load cell, the time on the scale and the speed of the belt. Belt feeders can achieve 0.25% accuracy."

Integration

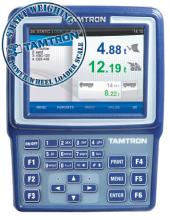

As well as being able to integrate weighing systems into management tools, it is also possible to use the data to improve safety. "Our 2180 weighing system for wheeled loaders has slope, ambient temperature and friction compensation which allow it to work to a high accuracy in more environments," said Vaasen. "The system will also soon include a safety feature to prevent overloading on slopes or by weight, which will control the hydraulics. We are working on a similar development for the excavator system too.

"This was born out of being aware that more companies are safety conscious these days and it goes beyond regulations but a desire to protect staff.

Growth

According to Evans, where the growth is likely to be is in the use of trade approvable on-board weighing systems. "On a loading shovel, such systems are effectively a mobile weighbridge and the information this produces is suitable for use in commercial transactions," he explained.

"The cost is much lower than that of a new weighbridge and they are proving to be very useful on sites that are not permanently manned or operate part time. The system also offers quarries a back-up if the weighbridge is out of action for any reason or during peak periods.

"Telemetry can be combined with a trade approvable on-board weighing system i.e. vehicles enter the site to be loaded with aggregate via an order sent directly to the Loadmaster and once the loading cycle is complete, the job data is automatically transmitted back to the base unit and a weight ticket printed for the driver to take upon exit. This set-up reduces time vehicles are on-site, avoids time delays at a weighbridge and cuts out unnecessary vehicle movements due to over or under loaded vehicles.

"Telemetry can be combined with a trade approvable on-board weighing system, so when vehicles enter the site to be loaded with aggregate via an order sent directly to the Loadmaster and once the loading cycle is complete, the job data is automatically transmitted back to the base unit and a weight ticket printed for the driver to take upon exit.

This set-up reduces time vehicles are on-site, avoids time delays at a weighbridge and cuts out unnecessary vehicle movements due to over or under loaded vehicles." However, Buxton said more emphasis was needed on maintenance of such systems. "If weighing is used for saleable products the accuracy needs to be verified and too often the calibration is not being checked between legal inspections and this should be added to maintenance programmes," he said.