The growth in the construction market worldwide is giving rise to a surge in demand for concrete products, concrete pipes and shafts as well as precast components.

This demand is in turn boosting developments among the manufacturers of the machinery and plant that is used to produce these components, say the organisers of

At the event, being held in Munich, Germany, from 15-21 April, 2013, a range of new products made of concrete and other materials will be on show at the booths of systems suppliers and components specialists, across the spectrum from new-comers to market leaders.

The German Engineering Federation (

A recent survey of selected German building materials machinery manufacturers, carried out by the Weimar-based Institute for Applied Research in Building (IAB – Institut für Angewandte Bauforschung), revealed that sales growth is expected to come in particular in the markets abroad.

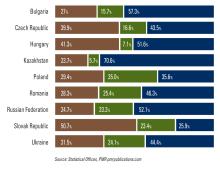

Demand was especially strong, it noted, in the emerging markets: China, India, certain countries in Eastern Europe and some of the former Soviet republics.

The report identified strong interest in turnkey production systems where manufacturing expertise and services were also included in the package.

For example, Vollert Anlagenbau of Weinsberg claims that it has delivered India’s first modern pallet circuit system, used by construction company Precast India Infrastructures at its production plant in Pune, western India, outputting up to 120m² of precast concrete walls/hour per hour, as well as precast concrete floors and hollow-core slabs for the subcontinent’s booming building industry.

At a new aerated concrete factory in the Ukraine, Systems manufacturer Masa of Porta Westfalica has increased daily output at the factory in Dnepropetrovsk from 1,000m³ to 1,400m³.

The IAB survey is also said to reveal a general rise in market interest in the wetcast production process where wet concrete is poured into flexible special moulds which have patterned inner faces. This pattern is retained on the surface of the concrete after curing. The technique enables companies to produce high-quality products with an individual look.