On-board weighing technology company Outset has launched a T1 Bluetooth transmission module, designed to allow direct and constant control of a vehicle’s load volumes and tyre conditions. The system works via an Android App for smartphone or tablet.

Outset, based in Vicenza in the north of Italy, says the module is suitable for use in articulated lorries, wheeled loaders, excavators, and aggregates dumper trucks.

All weighing and TPMS (tyre pressure monitoring system) data can be transmitted via a serial line to the on-board computer or directly in-cloud on external devices, helping users maintain the control and management of productivity, in addition to the safety of their vehicle fleet.

The data can be transmitted via GPS, SIM card or Wi-Fi to the cloud platform, with printed reports to ensure the continuous updating and management of the loading process and tyre monitoring activity.

Luca Toneatti, export area executive at Outset, says the company has more than twenty years' experience in on-board weighing. It supplies TPMS devices for commercial vehicles, earthmoving machines, mining, and logistic vehicles.

Outset technology is designed to provide precise and efficient weighing while loading, in addition to continuous monitoring of tyre pressure and temperature.

Toneatti says that Outset makes constant, significant investments in R&D to improve its products and develop new, innovative instruments that incorporate the best new technology. The company also works hard, he says, to maintain its reputation for developing user-friendly tech.

The company has an extensive network of authorised sales partners around the world, and plans to expand its network further in the coming years.

Outset provides a range of technologically advanced devices compliant with Industry 4.0 directives, and it works closely with operators to optimise loads. The company’s systems ensure that payloads stay within legal limits and that vehicles do not get overloaded.

In separate news, Outset says it has changed its legal form and become a “Benefit Company.” Outset says this move, made on 30 December 2021, formally recognises how it has established a raft of social responsibility and ethical policy commitments in recent years, all of which are now an integral part of the company's DNA.

“As a B Corp we operate responsibly, following sustainable and transparent criteria, which are rewriting the way of doing business globally,” says Toneatti.

A Benefit Company is one that integrates into its corporate purpose, in addition to profit objectives, the aim of having a positive impact on society and the biosphere, says Outset.

"First of all, we thought about the people who work with us, their well-being and happiness, the enhancement of their talents and the creation of new jobs," Toneatti adds.

"We aim to create a healthy and meritocratic environment where people are happy in the company and put passion into what they do."

The new hydraulic WK60 excavator scale from mobile weighing systems provider Pfreundt impresses with digital weighing data acquisition, precise measurement results and intuitive operation.

The WK60 excavator scale enables material weighing directly in the work process and thus fast and accurate loading of transport vehicles. Equipped with four pressure and four inclination sensors, the robust mobile weighing system reliably delivers precise measurement results even on uneven terrain. Digital management, analysis and further processing of the recorded weighing data is also easily possible through a connection to the Pfreundt web portal.

The weighing electronics are available in the three different versions, WK60-XS, WK60-S and WK60, and can be flexibly adapted to individual customer requirements and operating procedures thanks to the different functional scope of these versions. The hydraulic excavator scale can also be retrofitted at any time into excavators with mono booms of all manufacturer types.

By recording the weighing data directly during the work process, the hydraulic Pfreundt excavator scale enables fast and accurate loading of transport equipment. This accelerates logistical processes and optimally utilizes production capacities.

Due to the optimal loading of means of transport in compliance with the permissible total weight, overloading is avoided. Penalties as well as repair and maintenance costs due to overloading are saved.

The hydraulic excavator scale ensures transparency in the material flow. By analysing and evaluating the recorded data via the Pfreundt web portal, internal material movements can be traced. This helps to optimise the operating processes, e.g., the avoidance of idling - energy is saved, costs are reduced.

Pfreundt says the hydraulic WK60 excavator scale provides a number of benefits including: dynamic weighing in the working process for fast and accurate loading; precise weighing results even under extreme conditions; fast availability of weighing data even with a high number of short loading cycles; maximum freedom of movement of the machine is fully maintained; easy and intuitive operation of WK60 weighing electronics through 7-inch touch display; extensive and customisable master and weighing data management; and installation or retrofitting possible in excavators with mono booms from a wide range of manufacturers.

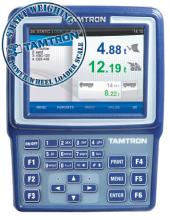

Tamtron Group says it is continuing to invest in growth and has entered into an agreement to acquire the entire share capital of fellow Finnish weighing technology company Lahti Precision.

“The acquisition will enable Tamtron to provide its customers an even wider global range of weighing and dispensing technologies, advanced SaaS solutions and lifecycle services to ensure customer success,” comments Tamtron Group MD Mikko Keskinen on the background of the arrangement.

“Lahti Precision’s System sales solutions form a new business sector and foundation to the Tamtron group which will help us serve an even wider international clientele.

“It is fantastic to be able to collaborate with the professionals of Lahti Precision and collaborate in the development of the most advanced solutions in the industry. Both companies have a strong culture of continuous development and therefore we will be a good match. Tamtron is in a phase of strong growth and the acquisition represents an important step in achieving our strategic objectives.

“I welcome the 94 experts of Lahti Precision Oy, the current and future customers, partners and stakeholders to build mutual success.”

Lahti Precision has more than a hundred years of weighing industry expertise, specialising in the development of industrial competitiveness. Its head office is in Lahti. The products and services of Lahti Precision cover industrial weighing solutions (e.g., truck scales, big bag stations, conveyor belt scales, dispensing systems, lifecycle services and calibrations) and mScales, a SaaS-based material-flow management system. During 2022, the company’s turnover reached €17m and EBITDA (earnings before interest, taxes, depreciation and amortisation) totalled €1.8m. The company employs 94 experts. The customer base consists of leading industrial, recycling, mining and logistics companies, including manufacturers of battery materials used in electric vehicles.

“Together with Tamtron, Lahti Precision will create a strong actor on the Finnish and Nordic markets,” says Juho Koskinen, managing director of Lahti Precision. “A comprehensive portfolio of weighing systems, a Nordics-wide after-sales service network and the combination of two market-leading SaaS-based material-flow management systems will provide significant benefits to customers now and going forward. Lahti as a location will be a major centre of expertise in the heavy weighing sector of Tamtron Group. We are also confident that our international success will develop further with the addition of Tamtron’s foreign subsidiaries and partners into our distribution channel.”