The system continually measures hydraulic pressure using up to four sensors, with pressure signals captured and filtered through a weighing arc provided by inclination sensors measuring the angle of the main boom. All signals are processed in the RDS Technology Smart Box and the resultant weight calculation is sent to the terminal mounted in the cabin.

The SQL database capability with up to eight reference fields is designed to provide virtually unlimited inputs of containers, customers, trucks, hauliers, locations, destinations and notes.

RDS Technology says that with the ever-increasing focus on safe loading of containers, the new Liftlog 1000 is a cost-effective weighing instrument designed for forklifts working in a dispatch port environment.

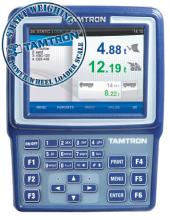

Weighing on the forklift removes the need to travel to a static floor scale, often remotely located from the stock location or loading bay. The Liftlog 1000 informs the operator of the load as a calculated weight in tonnes, kg, lbs and US tons.