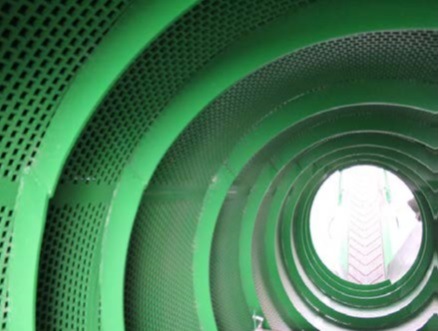

The new option, available on all models, combines the drum incline found in all McCloskey trommels with the enhanced product quality control of a spiral drum.

A spiral drum screens in a different way to the standard lift and drop system usually used in a trommel. It is able to prevent ‘“spearing’ where elongated material is lifted and thrown through the screen opening. This lack of spearing ensures that tight product specifications can be met. The drawback of the spiral drum is less ability to break up material by the aggressive lift and throw of a standard drum.

Used for applications such as green waste, mulch, and compost, McCloskey’s spiral screen increases control of material flow, maximising material sorting per load.

While load height in spiral drum trommels is often much lower than the inclined design, McCloskey says it combines the standard incline featured on all McCloskey trommels, with the highly efficient output of the spiral drum to deliver higher productivity.

Key features of the McCloskey drum are the ability to offer it as a punch plate or supply the frame around which screen cloth of any desired size can be wrapped.

McCloskey developed its first spiral drums thre years ago and is now ready to deliver this design option across the whole range.

The spiral drum will be available on 500, 600, and 700 series trommels. All trommels in the line-up take advantage of McCloskey’s Drum X-Change System, which allows operators to remove the drum from the trommel with a loader, and swap it out with another drum in 15 minutes.