New Zealand-based Loadrite has launched a suite of solutions for in quarry management. Claire Symes reports

The advent of asset management systems for construction equipment has helped quarry operators to significantly improve efficiency of their operations. But the integration of weighing systems adds a new dimension to the performance improvement on offer, according to New Zealand-based

Loadrite has just launched a new and updated range of systems to help improve productivity both in the pit and the loading yard.

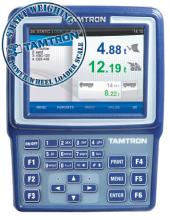

New to the range is the automatic weighing system for excavators - the X-weigh 2350. The company has had a similar system for wheeled loaders for some time but the system has been re-configured for the excavator geometry with additional sensors. Like the wheeled loader version, it allows loads to be weighed on the move.

Loadrite international technical sales manager Lars Marsden said, "The X-weigh systems allow quarry operators to track cycle times accurately and ensure maximum efficiency is being achieved with each load."

Information from on-board weighing systems can be effectively linked using the new Pit Boss, which is designed to give customised productivity reports based on weighing data. According to Marsden, the system helps to ensure that trucks are loaded with the optimum amount of material to improve productivity.

"Under loaded trucks mean that more cycles are needed but overloaded ones can cause both tyre and machine damage," he said. "Analysis of the loading from each blast can help quarry operators to check the efficiency of the blast, compare efficiency of different trucks and see in real time the impact of problems like a wet or damaged haul road can cause. Quarry owners can also use the information to plan maintenance for machines based on the actual tonnage that each item has moved rather than just by engine hours." According to Loadrite, trials of the Pit Boss in several quarries have shown that the system can offer immediate gains in productivity of 15%.

The productivity improvements offered by the Pit Boss in the quarry itself are matched in the loading yard by the Loadout Management System. Loadout uses RFID tags - microchips with a built in antenna - to track customers' trucks as they enter and move round the aggregate loading yard. The tag allows the system to display the information for the load, the wait time and the order and link a quarry's weigh bridge ticketing system with the wheeled loader operators.

"Loadout uses the details to prioritise the loading by wait time and product to ensure maximum efficiency for machines in the loading bays and minimum wait times for customers," said Marsden. "It also tracks the material, matches it to the order and feeds the information through to invoicing and can also be accessed by customers via a web-based application, which adds visibility."

The company is working on the final field trials of Loadout with the X-weigh system. Marsden said that the two are linked by a "black box" and is being tested by two US quarries - a Luck Stone quarry in Virginia and a