A new Norwegian weighing system can help save time and reduce fuel consumption. Alan Peterson reports

Modern wheel loaders are well designed for increased productivity under any condition but the addition of an onboard weighing system could further improve productivity.

The Loadtronic weighing system, from Norway-based

However, Aanderaa has said it is essential that the weighing is performed while driving and that the system never tells the driver to stop or slow down the speed. Loadtronic is a truly automatic and dynamic weighing system, said Aanderaa marketing manager Toralf Brunaes and is "the most efficient weighing system available in the market today." Loadtronic has been developed by AADI (short for Aanderaa Data Instruments AS) which produces sensors, instruments and systems enabling acquisition, validation and transmission of data for demanding environmental markets.

The Loadtronic system is automatic in the sense that the load in the bucket is weighed without any involvement from the operator. During normal operation the weighing sequence is activated automatically when the wheel loader is reversing away from the material heap after filling the bucket. The weighing begins as soon as the lifting arms have moved within the weighing range. The weight of the bucket is automatically added to the running total weight.

During the automatic weighing the display shows the current material weight, the running total weight, the number of bucket loads, as well as other various job details.

The dynamic lies in the fact that the system allows weighing while the machine operates normally without any interruption. This means that the driver does not have to stop the vehicle for weighing the load, and is free to concentrate on the driving and loading. The weighing is not even influenced by driving on uneven or very rough ground surface. The system never has to tell the operator to slow down the speed of driving and loading. This helps save time and money.

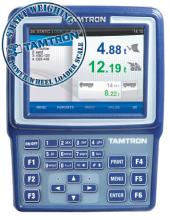

A new version - Loadtronic 3 - is to be launched shortly and of a main unit including a computer unit and a colour display. It has a robust and ergonomic construction and the operation is very user-friendly and self-explanatory, according to Brunaes.

Emphasis has been put on the graphical user interface part. All menus and displayed information are presented in colour and logically organised and structured to enable quick and precise handling. "Built-in help functions make the user manual superfluous," said Brunaes.

Loadtronic3 is mounted on the right corner post in the cabin and making it easy to reach and it records each operation when the system is active. The recording is linked to a specific job record, with reference to the type of truck, material, customer or location. The data is stored in the main unit and can be inspected and printed for customer receipt. Wireless communication is used for transmission of data between the wheel loader and a remote location.

Improvements over the Loadtronic2 include a CANBUS interface for all major wheeled loader brands, calibration for 10 different attachments and a structured, user-friendly menu structured based on Windows CE.

Loadtronic is marketed as a product for installation at the factory (branded or OEM) or as a stand alone system for retro installation. It is adaptable to all the major wheel loader brands available in Europe.