Still far and away the leading aggregates producer in Europe, Germany is maintaining its position and role as the stable core of the industry on the continent. But the overriding optimism of a year ago has been tempered somewhat by figures showing a recent sharp decline across the construction industry, writes Julie-Anne Ryan.

Industries other than construction, such as iron and steel production and processing, glass and ceramic industries and chemicals for example, also consumed about 10.5 million tonnes of quartz gravel and sand as special products. There were also 66.6 million tonnes of recycled building materials, accounting for 12% of aggregate demand.

The UEPG (

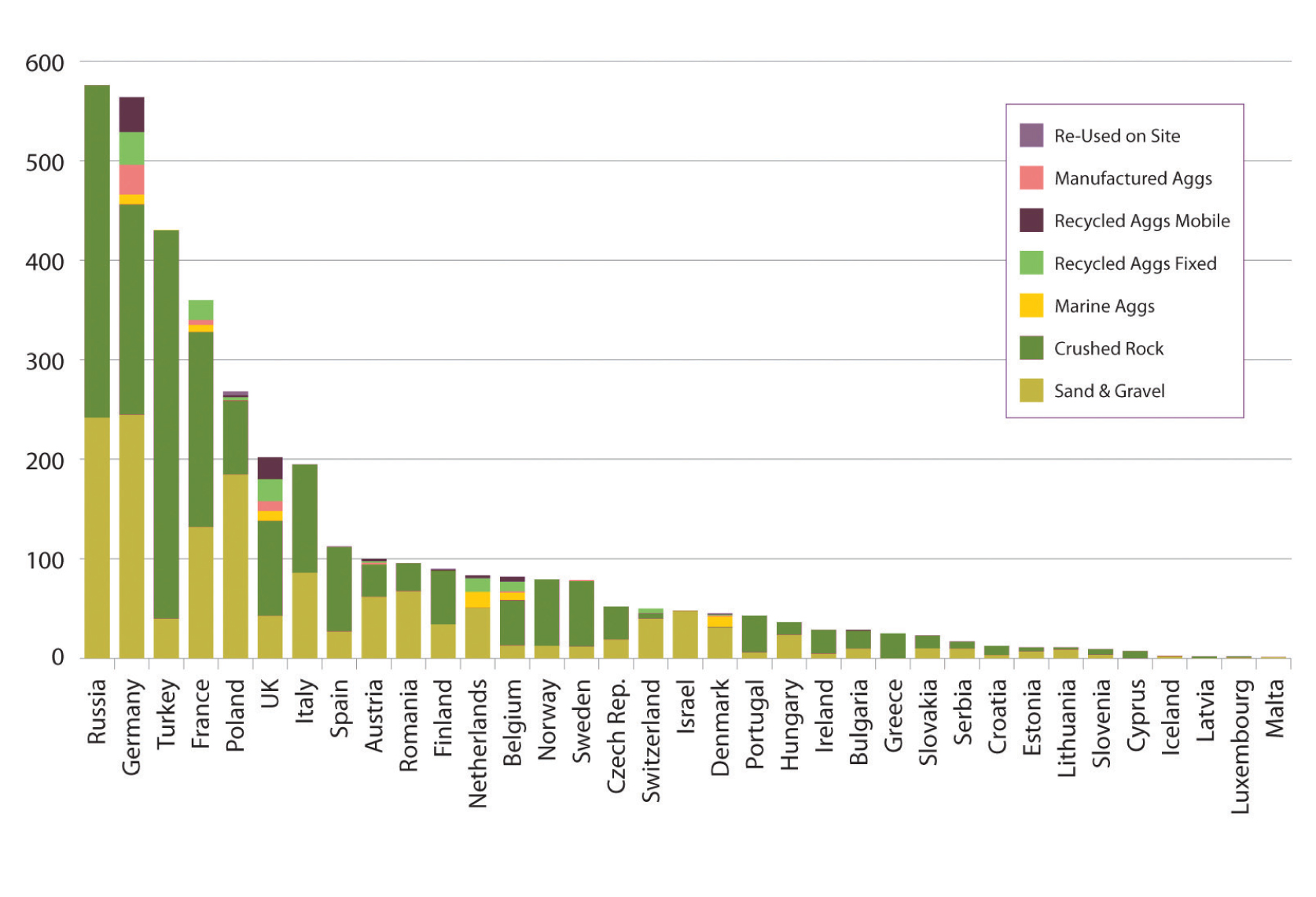

The annual review stated: “Focusing on the EU27 plus EFTA [European Free Trade Association] data, the total production for 2011 was just on 3 billion tonnes. It was 3.1% up on the previous year, mainly due to growth in Germany and Poland, partly offset by declines in Spain and some other countries. This tonnage came from 26,000 quarries and pits, operated by 15,000 companies (most of which are SMEs), with 238,000 employed. The industry annual turnover is in the order of €20 billion.”

Another national organisation, the German Building Materials Association (BBS) represents the business and industrial interests of 16 sub-sectors and around 4,000 companies with a total of 145,000 employees. It states that the German building materials industry generates rates of annual turnover of more than €30 billion.

The BBS expected for 2014 an increase in public construction spending by 5%. How close was it in its prediction? In fact there are conflicting reports of Germany’s fortunes in that department.

A report in January said that sales in the German construction sector would climb by 3.5% this year thanks largely to strong demand for homes.

Germany’s HDB and ZDB construction groups said that sales would increase to €98.6 billion this year from €95.3 billion in 2013, helped by a 5% increase in housebuilding. It credited low interest rates in residential construction, which made it attractive for investors and encouraged consumers to buy homes instead of keeping their cash in banks.

HDB and ZDB said construction sales had jumped by 2.5% in 2013, beating a forecast for 2% growth.

And yet just six months later the Germany Construction Purchasing Managers’ Index (PMI) showed that building activity had declined across all of the three monitored categories, and at the sharpest rate in 15 months amid a steep fall in new orders.

Meanwhile, companies reduced their workforce numbers for the first time since March last year.

The report stated: “Work on residential building projects fell for a third consecutive month, albeit only marginally.

“Meanwhile, commercial activity declined for the first time in 14 months and at a slightly steeper rate than housing activity. By far the sharpest drop in activity was seen in the civil engineering sub-sector, with the rate of contraction the fastest in over two years. Moreover, nearly one-third of the survey panel reported a decline.

“As has been the case since April 2012, new orders placed at German construction companies fell in June. The rate at which new business declined was the joint highest in 15 months.”

Importantly for the aggregates industry, German constructors lowered their purchasing activity in June. Input buying fell for the third month in a row and at the quickest pace since March 2013.

There was, however, optimism in terms of the 12-month outlook for activity, where the level of positive sentiment was the highest in three months and linked to greater workloads in the pipeline.

Oliver Kolodseike, economist at Markit, which produced the report, said: “The only bright spot in the survey results is a positive outlook for the year ahead, which companies generally linked to work in the pipeline.”

Key players are continuing to ride the waves, as they must, with a variety of plans, investments, sales and mergers.

The transaction includes one cement plant, two grinding stations (total cement capacity of 2.5 million tonnes); one slag granulator; 22 aggregates locations and 79 ready-mixed concrete plants. They would be combined with Holcim’s existing northern German operations. The transactions should be closed in the second half of 2014.

German based global group

The group, which employs 4,000 people in Germany, said its improved sales figures were down to successful price increases and improved cost control. Despite this, the group still reported a net loss of €108 million for the period, although this was better than the €187 million loss in the first quarter of 2013.

Lafarge and Holcim have committed to shed around €5 billion of assets to secure approval from competition authorities for their proposed merger. While HeidelbergCement wants to prioritise debt reduction, it may seize opportunities to snap up assets.

A

Kiesel has been the national distributor for

“We are proud to reach the No.1 position with hydraulic excavators above 45tonnes. The customers appreciate the high quality, performance, service capability and engagement of our organisation. Finally, the total cost of ownership is the key target,” says the company.

Hitachi points out that as the production of cement and natural raw materials decreased by about 10-15%, customers became more reserved in their willingness to invest in new equipment.

But, as a spokesman said: “This industry invests with an eye to the long-term.

“Cost reduction and optimisation of the processes are the key words for the future.”

Hitachi says its E-Service is an example of how customers can optimise their machine control and thus their profit.

“Competitive pressures, environmental regulations and sustainability shape the German quarry market. However, the regional production and mining of raw materials is necessary and is an important economic factor.

Only with the use of latest technology can we make this possible,” says Hitachi.

German company Amberger Kaolinwerke (AKW), a subsidiary of Quarzwerke, is investing €25 million in a new sand and gravel plant in Schnaittenbach and €15 million in Hirschau in the next few years.

The two plants employ about 500 staff. In Schnaittenbach, AKW will extract kaolin and quartz sand for a minimum of 40 years for the ceramics, paper, glass and construction chemicals industries.

MPA and the Aggregates Levy

In our last Market Report mention was made of the

To clarify the MPA’s position on the Levy, Nigel Jackson, MPA chief executive, said:“The MPA and prior to that QPA have always stated that the Aggregates Levy is a bad environmental tax and both organisations have been consistently opposed to it. Both Treasury and BIS are aware of the MPA view which we repeat regularly. Our strategy has been to try and mitigate the rate of growth of the levy which to date is worth around £70million as a result of three freezes in indexation we alone have argued for.

“MPA has taken the view that Government is unlikely to remove the levy as it is ‘hard baked’ into both Treasury forecasts and environmental thinking. We have been aware from the outset that the exemptions and reliefs would be liable to both legitimate use and abuse and would require modification at some point with the likelihood that the Treasury would seize the opportunity to increase its tax take from the sector rather than reduce it.

“The overriding issue for our members has been the creation of a level playing field and consistent and rigorous enforcement. MPA has taken the view that whatever the outcome of any legal action either in the UK or EU the Government ‘owns the goalposts’ and will move them to recover revenues whatever the justification.”