ABC supports construction industry inclusion

US industry trade association Associated Builders and Contractors (ABC) has given its strong support for the second annual Construction Inclusion Week, which started on October 17, and the need to champion and foster inclusion, diversity and equity throughout the construction industry.

Boral appoints new CFO

Australian building materials provider Boral has appointed Belinda Shaw as its new chief financial officer.

New CSC rating system rewards concrete recycling practices

The Concrete Sustainability Council (CSC) has introduced the new R-Module Version 2.1 which has been enhanced with a “Star” system that rewards maximising the use of recycled material and aggregates in fresh concrete.

Permission for pipeline to help UK quarrying's road to net-zero

UK-based liquefied petroleum gas (LPG) supplier Flogas Britain has been granted planning permission to construct a gas pipeline from Bristol Port into the LPG storage terminal at Avonmouth near Bristol.

Lafarge SA resolves Syria operations case with DoJ

Building materials provider Holcim says it supports the agreement reached by Lafarge SA with the U.S. Department of Justice (DOJ) to resolve the DOJ’s inquiry into Lafarge SA and its long-defunct subsidiary Lafarge Cement Syria (LCS).

Keestrack is on track with the M5 engine unit

To facilitate this, featuring on the Keestrack stand is the latest M5 tracked engine unit which carries a Cummins X12 EU Stage V engine and alternator. It delivers 383kW, 450kVA to drive all electric equipment at 197g/kWh.

The tracked engine – the perfect back up for the ZERO drive machines where there is no source of electricity on site – is part of Keestrack’s lengthy engine/gen set portfolio. Keestrack introduced a few years ago the first drop off module, a diesel engine with integrated gen-set, which can power several e-driven machines. It is placed a few meters from the machine in a less dusty environment and allows easier access for service and maintenance, unlike units that are built into a machine’s chassis.

One step further is the introduction of the tracked engine/generator units. These supply connected Keestrack crushers, screeners and stackers directly with electricity in case there is no plug in connection from the grid available. This way the economic advantages of the complete production train will rise due to using only one engine for several machines.

Doosan enters 10-tonne class with the DX100W-7

The 10-tonne weight class is new to the Doosan range and the DX100W-7 offers a high performance for urban and road maintenance applications. The integral 1.35-tonne counterweight ensures the highest stability for lifting work in combination with the articulated boom and long arm. The boom ensures that the operator can position the machine as close as possible to trucks during loading.

In addition, the DX100W-7 offers maximised lifting capacities and digging forces, as well as satisfying a requirement in some countries for a wheeled excavator with a travelling height of under 4m.

Other safety features include a ROPS cab with a premium seat as standard. An operator can use the large touch screen to easily browse all machine settings, including the view from the standard side and rear view cameras. The availability on the DX100W-7 of an optional 360° all-around view camera, linked with an optional ultrasonic detection system is another exclusive for a machine of this size, says Doosan.

With 75kW of power at 2000 RPM provided by a Doosan D34 G2 Stage V engine, the DX100W-7 has the highest engine power, hydraulic flow and traction force in this class. The high flow from the smooth and precise hydraulic system can drive all kinds of attachments. In addition, there are two different pumps providing independent hydraulic flow for the transmission and to fully power hydraulic tools on the front end.

The new DX100W-7 comes with DoosanCONNECT TMS 3.0 wireless fleet monitoring system.

Lay it out with BEUMER’s Layouting Tool

No two conveying systems are alike, even if the primary task of transporting bulk material from A to B appears comparable. The components and the system must be adapted to the material being conveyed. The mass flow to be conveyed and height differences that need to be overcome over the length of the conveyor line are important factors that must be addressed when designing a system.

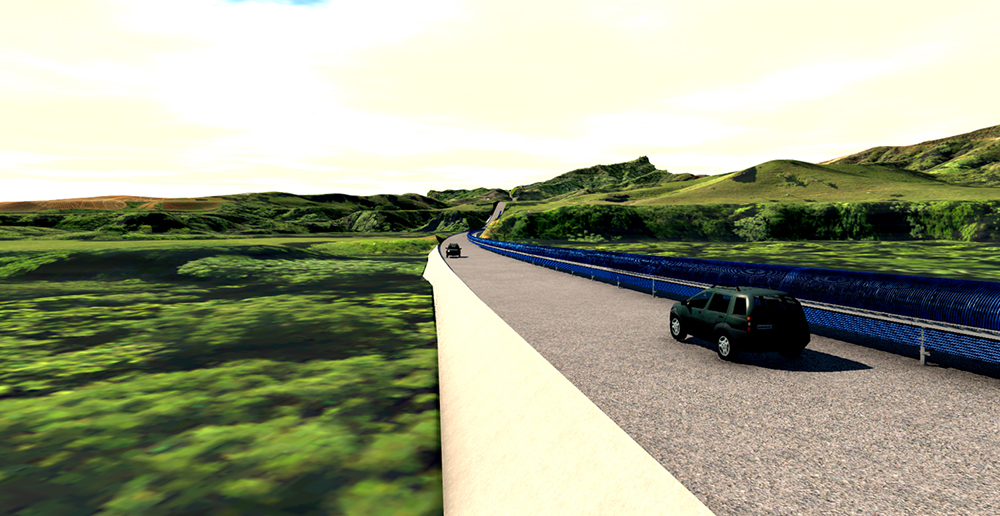

The right layout is all-important and the BEUMER Overland Layouting Tool is central for ascertaining the ideal layout for the system at an early stage of the project and designing the ideal conveying solution together with the customer.

It generates a digital 3D model of the conveyor in the virtual landscape during project planning, more or less automatically, according to the company. The critical topography data can either be provided by customers or drones that capture terrain data. These 3D visualisations are also ideal for supporting mining companies in their public relations work.

Important factors such as cut-and-fill volumes - the necessary excavation work - and the required steel structures for the conveyor can be evaluated and illustrated on this basis. This procedure considerably accelerates the project planning process and enables BEUMER to provide project-critical data to the customer at an early stage of the project.

Topography has a significant influence on the design of the conveying system. An in-depth analysis of various dynamic load cases and a thorough investigation of the technically feasible horizontal and vertical curve radii must be conducted to design the system in the most efficient and environmentally friendly way. This is especially true for longer and more difficult conveyor lines. Potential obstacles that must be considered during the planning phase include residential areas, roads and rivers.

Today, BEUMER can design curved overland conveyors of up to 20km or longer without the need for a transfer tower. The conveying capacities of a system like this are more than 20,000 tonnes per hour.

DEUTZ appoints Timo Krutoff as CFO & Labour Director

DEUTZ has appointed Timo Krutoff as its new Chief Financial Officer (CFO) and Labour Director.

Krutoff will join the Cologne-based engine manufacturer on December 1, 2022, as the member of the Board of Management with responsibility for finance, human resources, and information services. He will take over the role of CFO from Dr. Sebastian C. Schulte, who will continue to carry out the duties on an interim basis alongside his role as CEO until Krutoff joins.

CDE named one of Ireland's best managed companies

Wet processing equipment provider CDE has been named as one of the best managed companies on the island of Ireland.

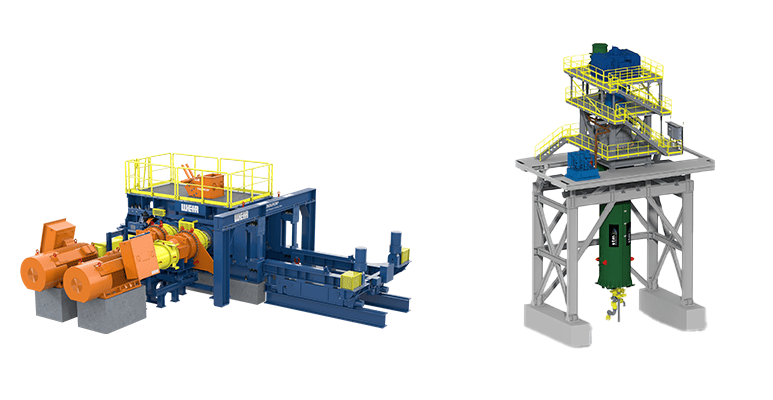

Weir and STM partner for sustainable coarse grinding

Weir Minerals has formed an alliance with Swiss Tower Mills Minerals (STM) in which Weir will market STM’s vertical stirred grinding mills for coarse grinding applications worldwide.

Conveying expertise

New product lines and a wealth of new technical expert analysis are enriching the conveyors area of the global quarrying equipment market

FMB calls for green homes strategy to boost economic growth

The 2% fall in repair, maintenance and improvement (RMI) work in the building industry revealed in the latest ONS figures on construction output in Great Britain, reflects reduced consumer spend as a result of the higher cost of living, according to the Federation of Master Builders (FMB).

CEMEX signs pallet re-use charter

Building materials supplier CEMEX has signed The Pallet LOOP Charter, which aims to reduce waste in the construction industry through a national pallet reuse scheme that supports the principles of the circular economy.

A new Komatsu WA600-8 “Stone Handler” delivered to Arthur Scheuermann GmbH

A few months ago, the fleet of Arthur Scheuermann GmbH in Kleinrinderfeld, Germany, was further strengthened by the purchase of a Komatsu WA600-8 “Stone Handler”, that will break down and transport shell limestone blocks. Sold and delivered by Schlüter für Baumaschinen, Germany’s largest distributor of Komatsu premium products, the robust and powerful wheel loader will advance shell limestone excavation in Arthur Scheuermann GmbH’s quarry.

Keestrack I4e crusher gets a redesign

Thanks to the RIC, or Reversible Impact Crusher, this machine is very flexible in the secondary and tertiary crushing of rock and recycling building materials, for example, asphalt. The specific design of the reversible horizontal impact crusher with a large variable crushing chamber, powerful rotor and electronically monitored hydraulic gap adjustment allows feed sizes of up to 250mm and ensures consistently high-quality end products of up to 0-2mm in closed circuit.

Titan America achieves state-of-the-art end-to-end cement plants' digitalisation

Titan America has successfully implemented digitalisation applications based on artificial intelligence (AI) and machine learning at its two cement plants, resulting in enhanced equipment throughput and reliability, reduced energy consumption, and improved product consistency and quality.

WCA conference emphasises need for cement decarbonisation in MENA

The World Cement Association’s Annual Conference has emphasised the urgency for the cement industry to decarbonise in the Middle East and North Africa (MENA) region.

Heidelberg Materials reaffirms 2030 carbon reduction targets

Heidelberg Materials has reconfirmed its 2030 carbon reduction targets, submitting them to the Science Based Targets initiative (SBTi) for validation in line with the recently announced 1.5°C scenario.